Multi-region complex damage defect feature comprehensive analysis method

A comprehensive analysis and multi-area technology, applied in the field of comprehensive analysis of multi-area complex damage defect characteristics, can solve problems such as the difficulty of obtaining approximate frontier surface solutions, and achieve the goal of improving the ability to express details, improve the performance of defect feature representation, and improve the detection ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0238] Such as Figure 1-3 Shown: a kind of multi-area complex damage defect characteristic comprehensive analysis method of the present invention, comprises the following steps:

[0239] Step 1. Perform multiple infrared inspections on large-size specimens to obtain multiple thermal image sequences of large-scale specimens, and use infrared feature extraction and infrared thermal image reconstruction algorithms to obtain large-scale specimens from multiple thermal image sequences Multiple reconstructed infrared thermal images, the specific methods include:

[0240] Step S11, multiple thermal image sequences obtained from the infrared camera are set in a three-dimensional matrix {S 1 ,...,S i ,...,S |C|}, where S i Indicates the thermal image sequence obtained by the infrared thermal imager in the i-th infrared detection, |C| indicates the total number of thermal image sequences, S i (m,n,t) represents the temperature value at the coordinate position of the mth row and nt...

Embodiment 2

[0345] Such as Figure 16-18 Shown: a kind of comprehensive analysis and identification method of complex micro-damage defect feature of the present invention, comprises the following steps:

[0346] Step 1. The specific method of using infrared feature extraction and infrared thermal image reconstruction algorithm to obtain reconstructed images from the thermal image sequence also includes:

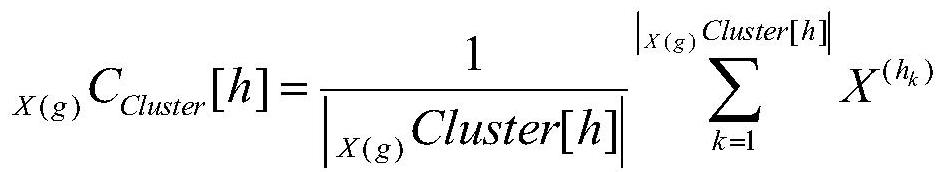

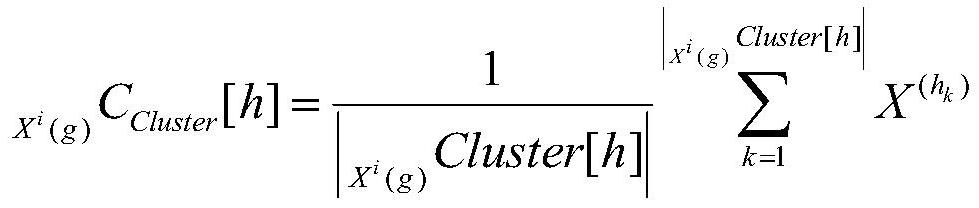

[0347] Step S11, based on the transient thermal response data extraction algorithm with block-variable step size, a valuable transient thermal response data set X(g) is extracted from the thermal image sequence S obtained by the infrared thermal imager, where , S(i,j,t) represents the pixel value of the i-th row and j-th column of the t-frame thermal image of the thermal image sequence, where t=1,...,T, T is the total number of frames, i=1 ,..., I, I is the total number of rows, j=1,..., J, J is the total number of columns;

[0348] Decompose the thermal image sequence into K distinct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com