Circulating heat preservation granary for brown rice or rice

A technology for granary and brown rice, which is applied to fruit hanging devices, botanical equipment and methods, gardening, etc., can solve the problems of uneven distribution of cooling effect, poor cooling effect of grain, and inability to achieve optimal cooling effect, so as to achieve cooling effect. Good effect, low energy consumption, uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

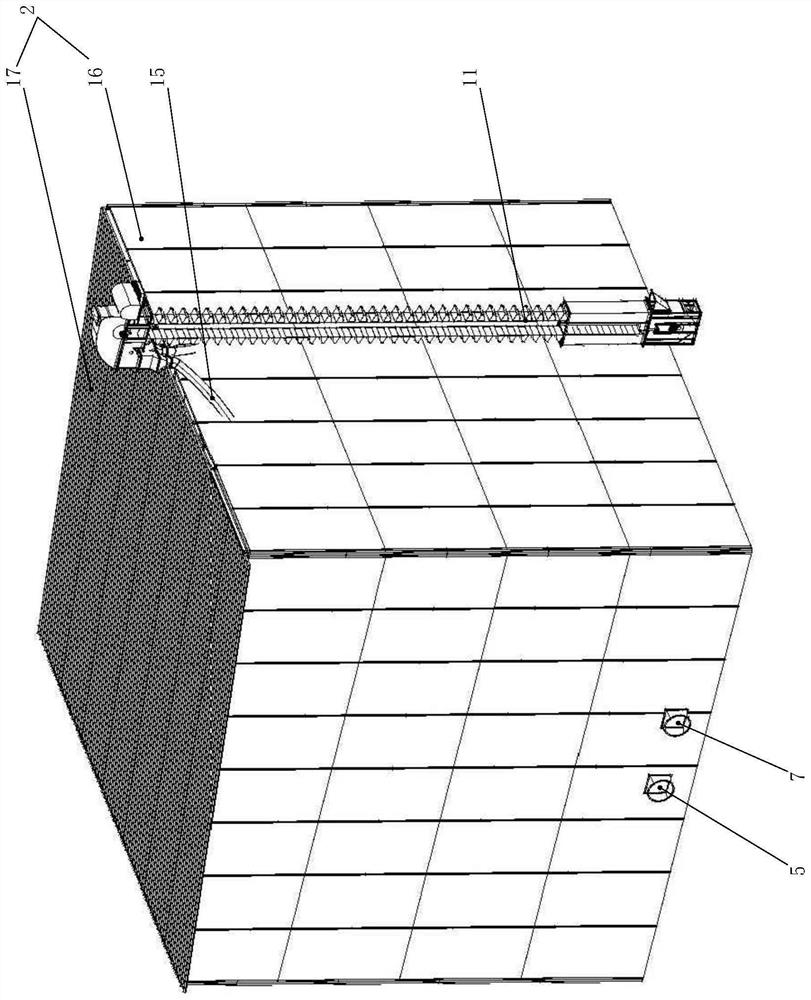

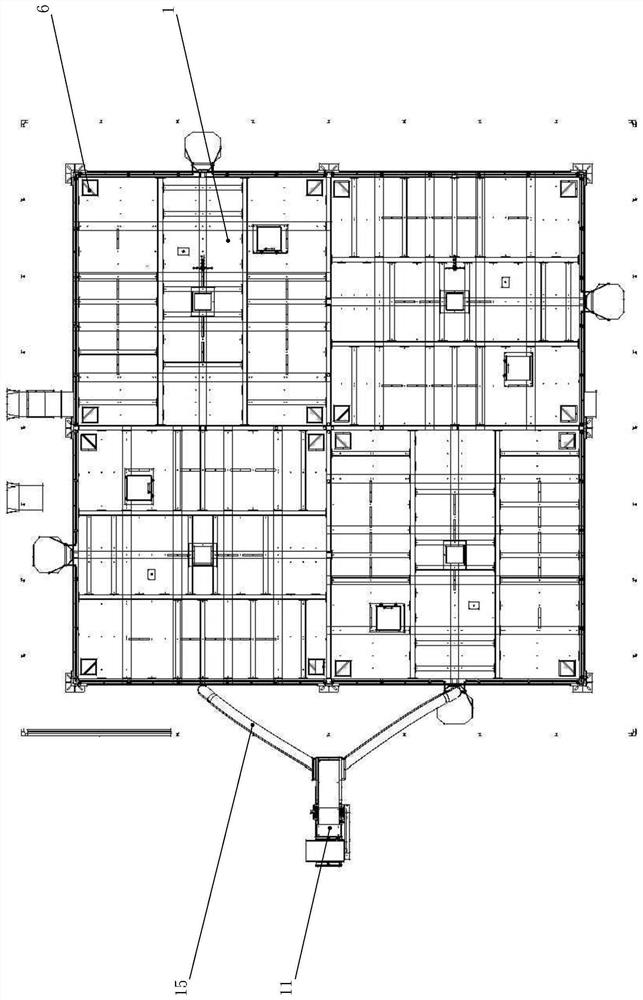

[0033] One kind or brown rice granary incubation cycle, comprising a body 1 with a barn, granary located outer periphery of the main body 1 are set insulation housing 2, 3 is formed, the outer housing 2 with a thermal insulating space between the housing 2 and an insulation body granary is provided with a cold air outlet end of the drum 4, the cold drum 4 penetrate through the pipeline 5 and holding the housing 2 communicates with the bottom of the inner cavity of the body 1 barn, granary body 3 defines a space communicating with the insulation on the wall surface 1 barn a body lumen through the inlet window 6, the insulation cover 2 defines an exhaust port 7, wherein the cold air inlet end of the drum 4 may be in communication with the exhaust port 7, to further re-use of energy. And, through the inlet window 6 may be opened directly, may set a one-way valve assembly, i.e. the open lumen of a body granary way valve cool air into the space within the insulation 3.

[0034] The pre...

Embodiment 2

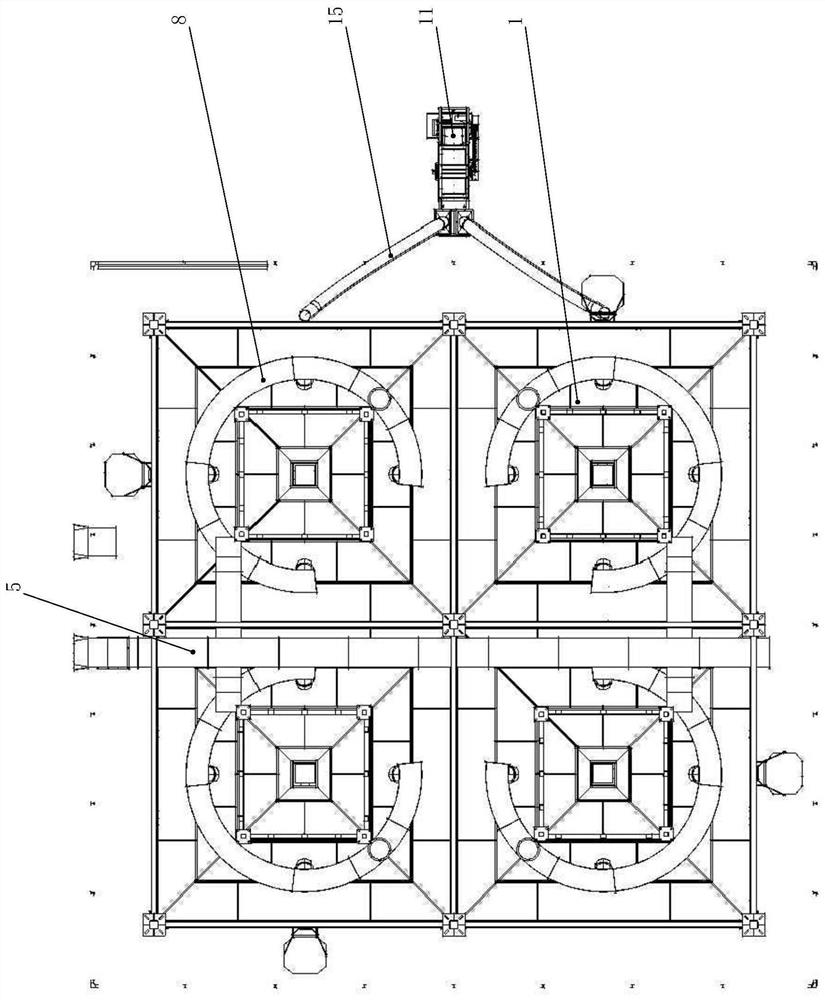

[0042] A configuration example of the above-described embodiment of the present embodiment is substantially the same, the main difference is: the barn is provided with a plurality of main body 1, and spaced, the outer periphery of each granary body 1 are set with said insulation housing 2. That is, each holding a barn housing body 2 a pair, corresponding to the food in order to be able to fill the lumen of the body 1 of the barn, which is a specific configuration of: further comprising insulation disposed outside of the housing 2 of the hoisting machine 11, to enhance the unit 11 and a port grain into the grain scraper conveyor communication port, the scraper conveyor 12 is located at the grain silos port 12 just above the main body 1, and the scraper conveyor 12 through an input port grain food conduit 13 insulation penetrating the housing 2 communicates with the intake port granary bread body 1, there can be input to the pipe 13 plugging food or valve means 14 is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com