Pond bottom sludge cleaning machine for penaeus chinensis breeding and sludge cleaning method

A Chinese prawn and cleaning machine technology, which is applied in application, fish farming, climate change adaptation, etc., can solve the problems of inconvenient cleaning of the bottom of the pond, inconvenient handling and cleaning, inability to mix and crush, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

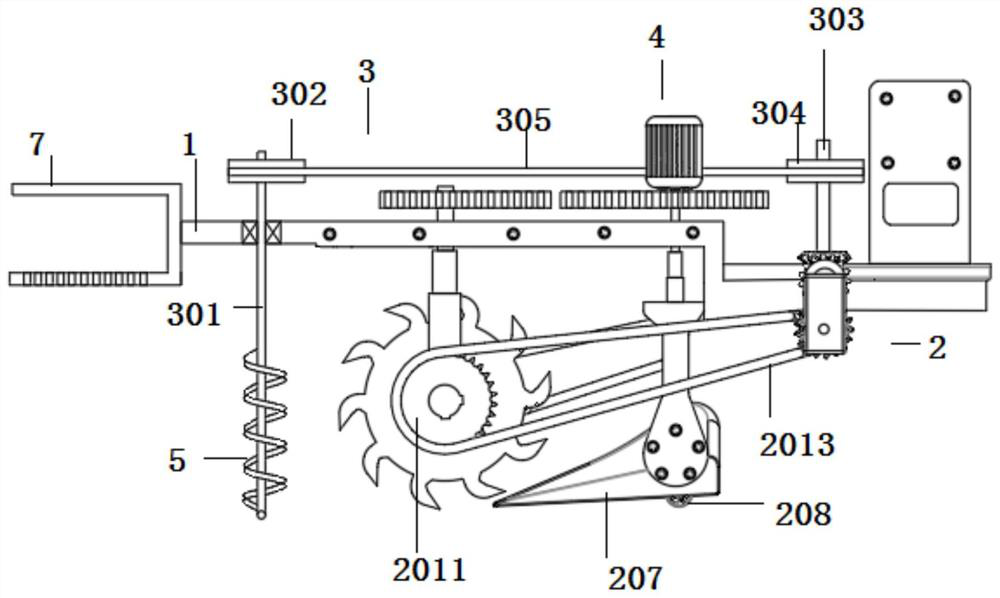

[0034] Such as Figure 1-6 Shown, the present invention is a kind of pond bottom cleaning machine for Chinese prawn seedlings, comprising a cleaning ship plate 1, and the bottom of the cleaning ship plate 1 is provided with a cleaning mechanism 2 and a sludge crushing mechanism 3;

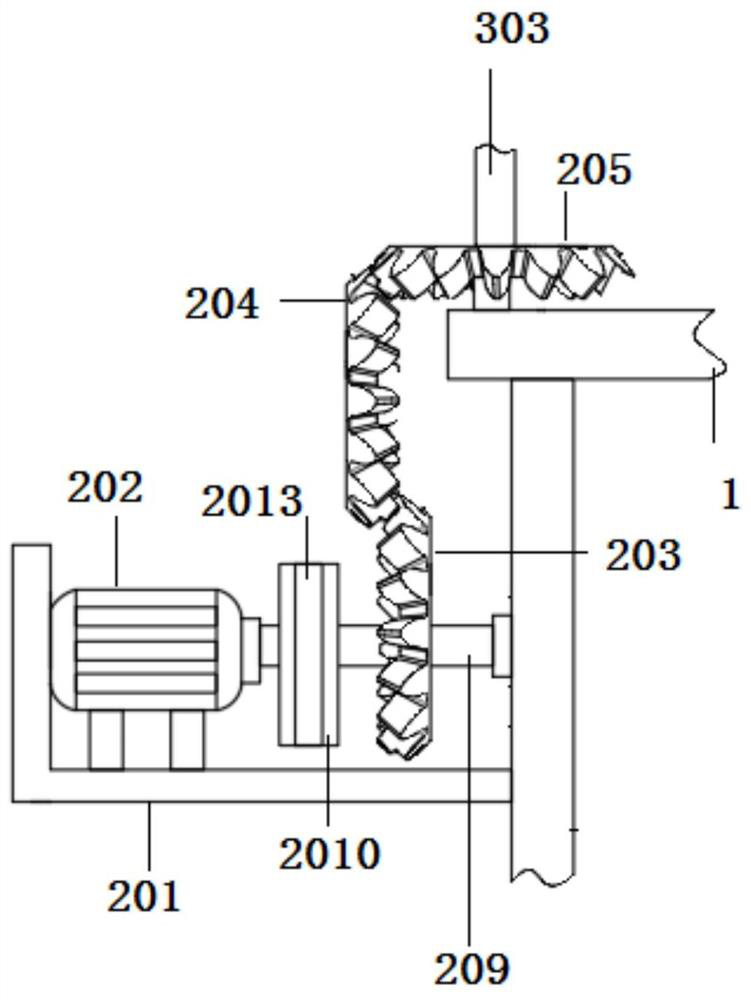

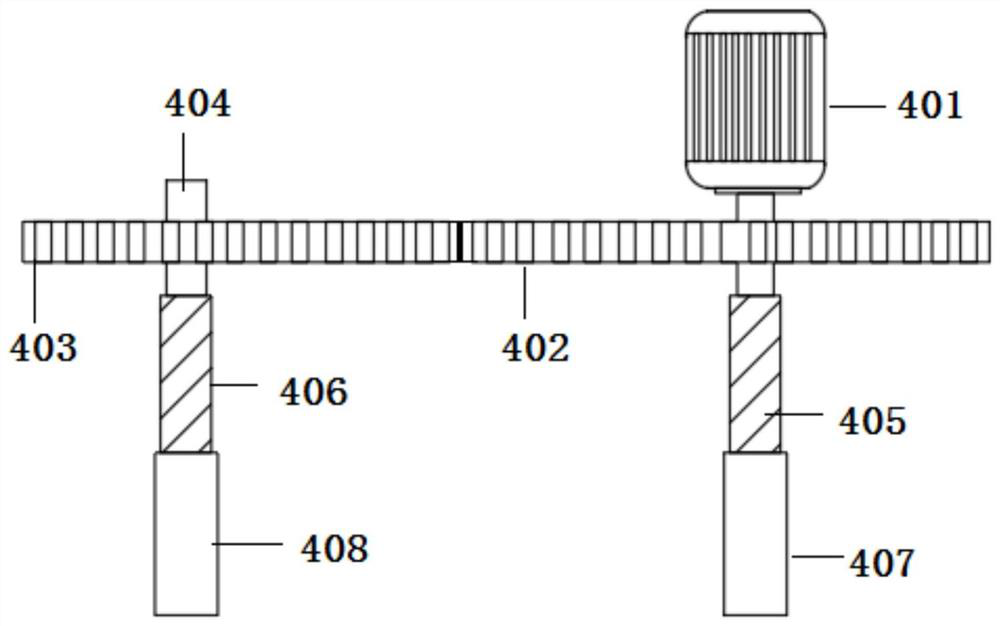

[0035]The cleaning mechanism 2 includes a gear installation cover 201, the side wall of the gear installation cover 201 is hinged to the front end side wall of the cleaning ship plate 1, and an underwater motor is installed on the side wall of the gear installation cover 201 close to the cleaning ship plate 1 202, the output end of the underwater motor 202 is sleeved with a driving gear 203, the first driven gear 204 is meshed above the driving gear 203, and the second driven gear is meshed with the first driven gear 204 above the cleaning ship plate 1 205, the bottom of the cleaning ship plate 1 is located on the left side of the underwater motor 202, and the cleaning drum 206 and the dirt loading...

Embodiment 2

[0038] A tank bottom cleaning machine for Chinese prawn seedlings, comprising a cleaning boat 1, the bottom of the cleaning boat 1 is provided with a cleaning mechanism 2 and a sludge crushing mechanism 3;

[0039] The cleaning mechanism 2 includes a gear installation cover 201, the side wall of the gear installation cover 201 is hinged to the front end side wall of the cleaning ship plate 1, and an underwater motor is installed on the side wall of the gear installation cover 201 close to the cleaning ship plate 1 202, the output end of the underwater motor 202 is sleeved with a driving gear 203, the first driven gear 204 is meshed above the driving gear 203, and the second driven gear is meshed with the first driven gear 204 above the cleaning ship plate 1 205, the bottom of the cleaning ship plate 1 is located on the left side of the underwater motor 202, and the cleaning drum 206 and the dirt loading box 207 are respectively installed through the lifting mechanism 4, and the...

Embodiment 3

[0043] A tank bottom cleaning machine for Chinese prawn seedlings, comprising a cleaning boat 1, the bottom of the cleaning boat 1 is provided with a cleaning mechanism 2 and a sludge crushing mechanism 3;

[0044] The cleaning mechanism 2 includes a gear installation cover 201, the side wall of the gear installation cover 201 is hinged to the front end side wall of the cleaning ship plate 1, and an underwater motor is installed on the side wall of the gear installation cover 201 close to the cleaning ship plate 1 202, the output end of the underwater motor 202 is sleeved with a driving gear 203, the first driven gear 204 is meshed above the driving gear 203, and the second driven gear is meshed with the first driven gear 204 above the cleaning ship plate 1 205, the bottom of the cleaning ship plate 1 is located on the left side of the underwater motor 202, and the cleaning drum 206 and the dirt loading box 207 are respectively installed through the lifting mechanism 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com