Skid-mounted LNG deacidification device and method thereof

A skid-mounted deacidification technology, applied in the energy field, can solve problems such as difficult equipment maintenance and repair, high production configuration costs, complex structure of deacidification devices, etc., to achieve the effect of convenient skid installation, cost reduction and investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

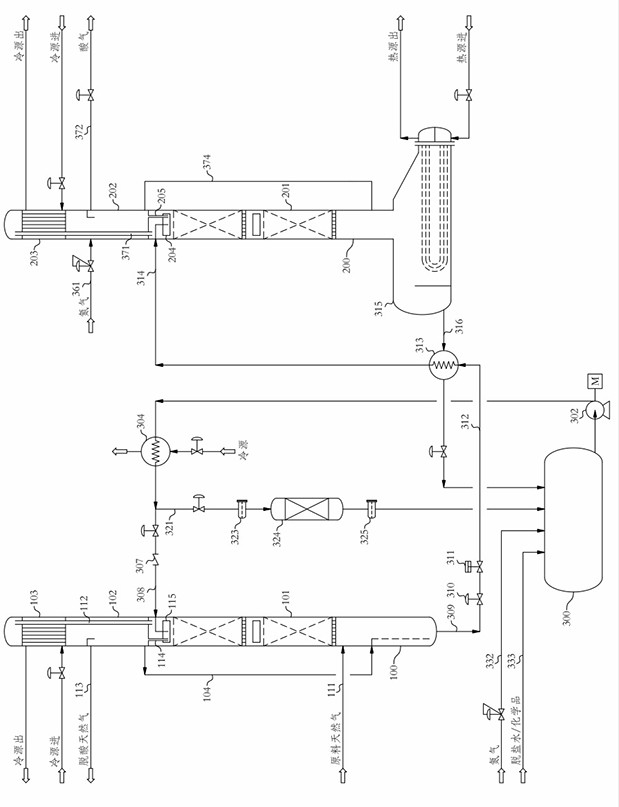

[0035] Such as figure 1 Shown:

[0036] The present invention provides a skid-mounted LNG deacidification device, which includes a combined absorption tower 100, a combined regeneration tower 200, a lean-rich amine heat exchanger 313, a lean amine cooler 304, an amine storage tank 300, and a lean amine pump 302;

[0037] Described combined absorption tower 100 is provided with cooling chamber one 103, separation chamber one 102 and absorption chamber 101 successively from top to bottom, and the top of described absorption chamber 101 is also provided with liquid distributor one 115, and described absorption chamber 101 and cooling Chamber one 103 is connected by steam pipeline one 112, said cooling chamber one 103 and separation chamber one 102 are connected by passage of cooling pipe, and the bottom of said separation chamber one 102 is provided with liquid distributor one 115. Flooding pipe one 114; the bottom end of the absorption chamber 101 of the combined absorption tow...

Embodiment 2

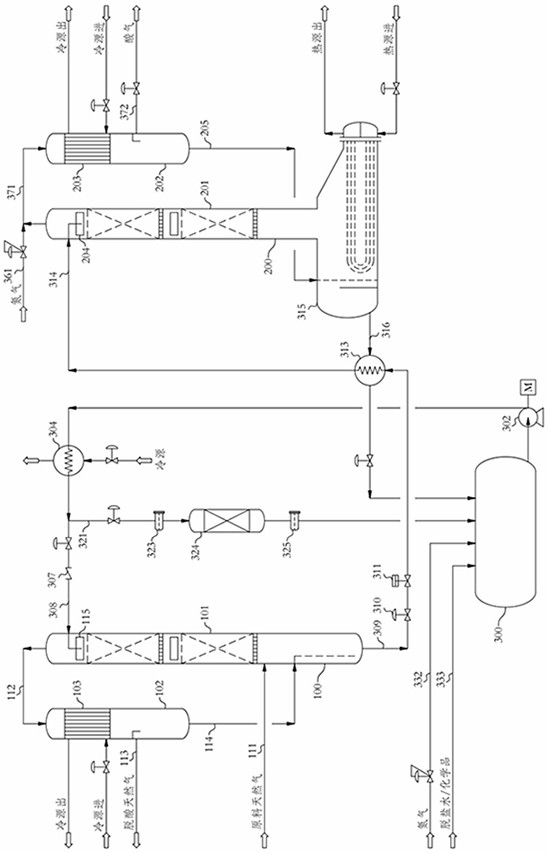

[0050] Such as figure 2 Shown:

[0051] The present invention provides a skid-mounted LNG deacidification device. Compared with Embodiment 1, the cooling chamber-103 and the separation chamber-102 of the combined absorption tower 100 of Embodiment 2 are combined, and the combined cooling chamber-103 and the separation chamber one 102 can be separately arranged outside the absorption chamber 101, and have the same height as the top of the absorption chamber 101; the steam pipeline one 112 communicates with the cooling chamber one 103 and the absorption chamber 101, and the said flooding pipe one 114 connects the separation chamber one 102 and the bottom of combined absorption tower 100.

[0052] The second cooling chamber 203 and the second separation chamber 202 of the combined regeneration tower 200 are arranged in combination, and the combined cooling chamber two 203 and the second separation chamber 202 can be separately arranged outside the absorption chamber 101 and hav...

Embodiment 3

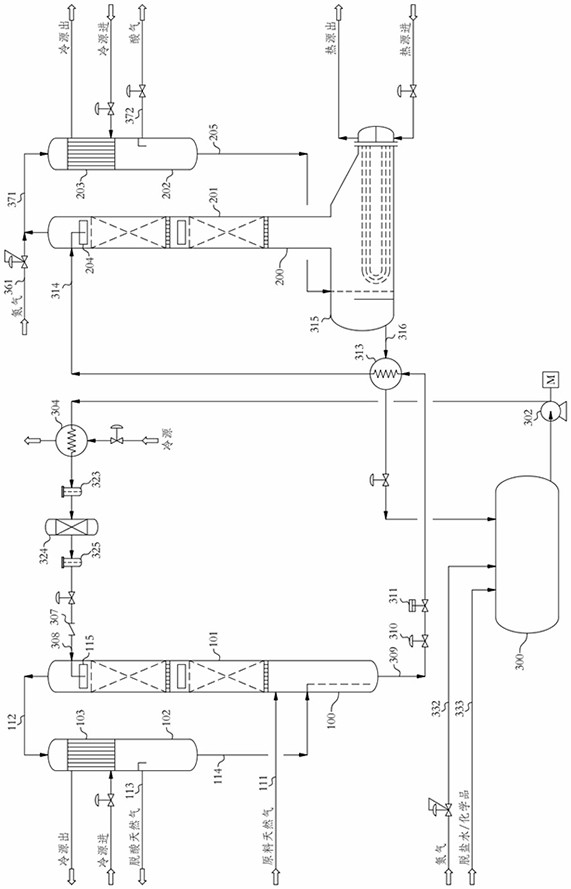

[0055] Such as image 3 Shown:

[0056] The present invention provides a skid-mounted LNG deacidification device. Compared with Example 2, in Example 3, the return pipeline 321 and the pipeline filter 1 323, lean amine filter 324, and pipeline filtration The second device 325 is installed on the pipeline between the lean amine cooler 304 and the lean amine liquid inlet pipe 308.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com