Reciprocating rolling type particle forming machine and forming method thereof

A pellet forming machine and rolling technology, which is applied in the field of reciprocating rolling pellet forming machine and its forming, can solve the problems such as unsustainable machine tool work, slow flow of raw materials, and reduce extrusion force, so as to achieve high processing efficiency and solve the problem of Easy to clog and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

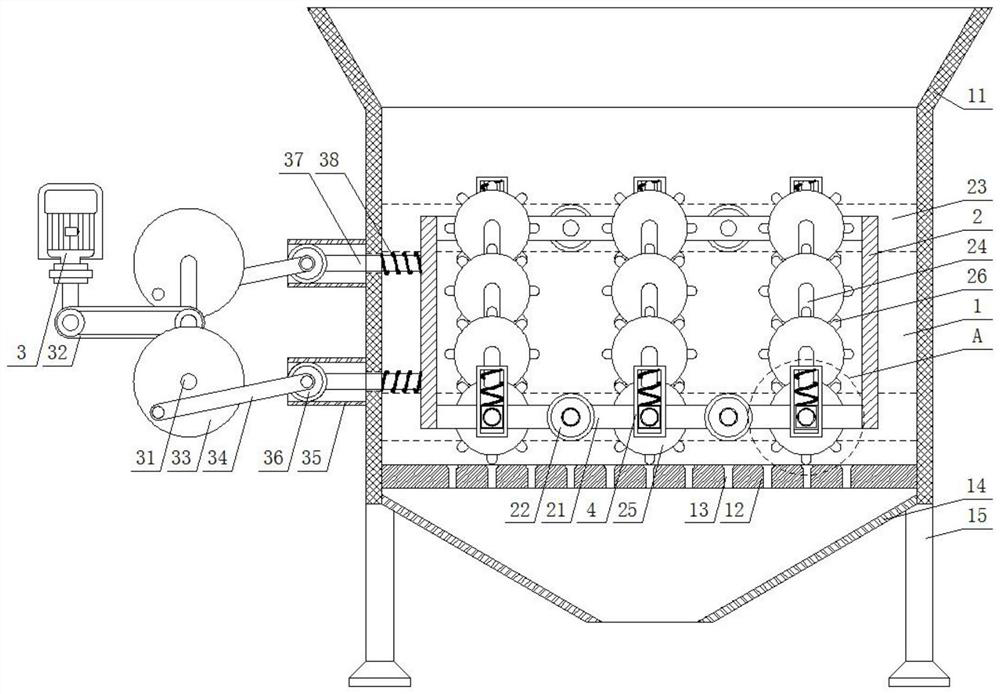

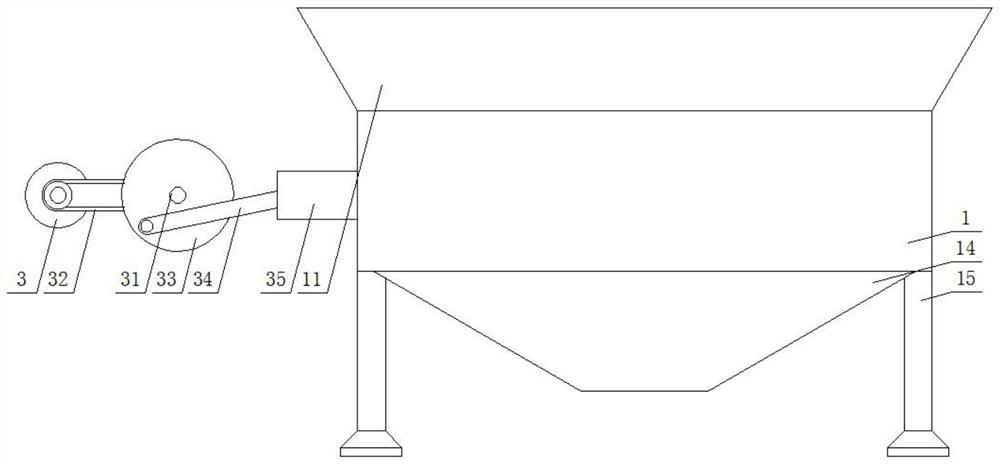

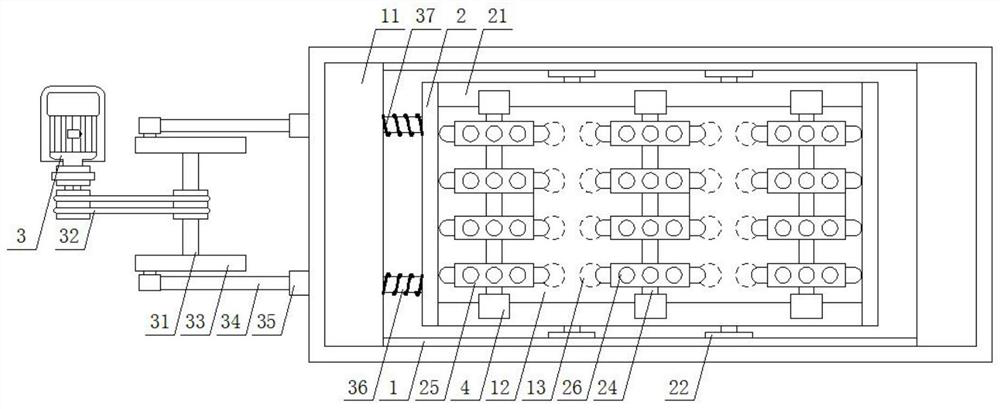

[0032] Embodiment 1: This embodiment provides a reciprocating rolling pellet molding machine, see Figure 1-4 Specifically, it includes a bottom box 1, a pressure regulating mechanism, and a turntable reciprocating mechanism. The bottom box 1 is in the shape of a rectangular box with its upper and lower sides open. A pair of reciprocating plates 2 placed in parallel in the longitudinal direction are provided in the bottom box 1 above, a pair of horizontal plates 21 fixed in parallel in the transverse direction are arranged between the two ends of the pair of reciprocating plates 2, a pair of reciprocating plates 2, a pair of transverse plates 21 are perpendicular to each other to form a rectangular frame, and a number of rolling shafts 24 placed longitudinally are arranged between a pair of horizontal plates 21, and both ends of each rolling shaft 24 are connected to a pair of horizontal plates 21 through a pressure regulating mechanism;

[0033] One side of the bottom box 1 i...

Embodiment 2

[0040] Embodiment 2: In Embodiment 1, there is also the problem that the forming hole is easy to block. Therefore, on the basis of Embodiment 1, this embodiment also includes:

[0041] In the present invention, the pressure regulating mechanism includes a rectangular limiting frame 4 and a square block 43, and a rectangular limiting frame 4 is arranged on the inner side of the horizontal plate 21 at positions corresponding to the two ends of the rolling shaft 24. The bottom of the frame 4 is provided with a square block 43 that slides up and down. The middle part of the square block 43 is provided with a fixed bearing, and the two ends of the rolling shaft 24 are inserted in the corresponding fixed bearings; A limit column 41 is provided, and a pressure spring 42 is set on the limit column 41, and the bottom end of the pressure spring 42 is fixedly connected with the middle part of the top surface of the square block 43;

[0042] When there are hard objects in the material, un...

Embodiment 3

[0043] Embodiment three: see Figure 5 , in this embodiment, the present invention also proposes a molding method of a reciprocating rolling pellet molding machine, comprising the following steps:

[0044] Step 1, start the servo motor 3, the motor shaft of the servo motor 3 drives the driving shaft and the driving pulley to rotate synchronously, drives the driven pulley and the linkage shaft 31 to rotate synchronously through the driving belt 32, and then drives the turntable 33 and the eccentric pin shaft to rotate synchronously, Under the cooperation of the hinge action, the hinge rod 34 drives the reciprocating shaft and the reciprocating wheel 36 to perform reciprocating rolling operations along the rectangular channel steel 35;

[0045] Step 2, at the same time, the reciprocating shaft drives the rectangular sliding rod 37 to reciprocate and slide along the rectangular sliding hole, driving the tension spring 38 to undergo reciprocating compression deformation, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com