Horizontal positioning and sinkage detection compensation method for marine multi-fulcrum boring machine boring rod

A technology of horizontal positioning and compensation method, which is used in measuring/indicating equipment, automatic control devices, feeding devices, etc., can solve the problems of inability to meet the requirements of multi-pivot boring bar detection and compensation adjustment, cumbersome detection, and reduced accuracy. , to reduce the natural subsidence, ensure the accuracy, and eliminate the straightness excess.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

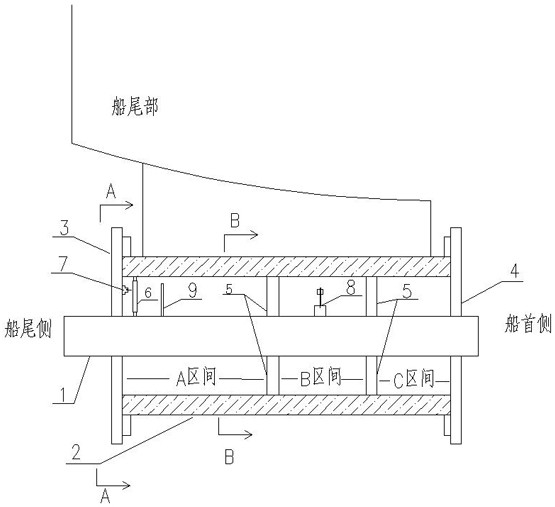

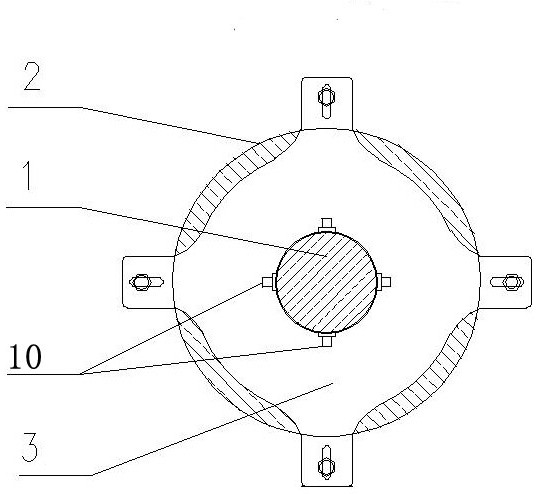

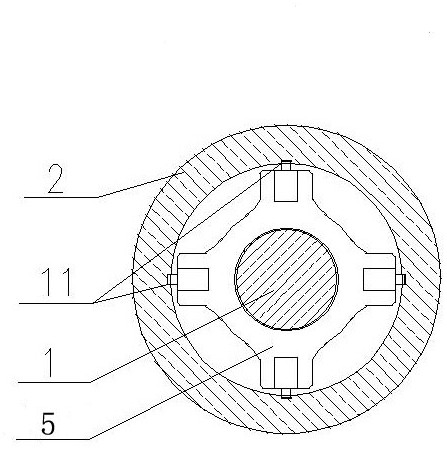

[0027] see Figure 1 to Figure 3 , a kind of marine multi-fulcrum boring bar horizontal positioning and sinking amount detection and compensation method provided by the present invention is carried out according to the following steps:

[0028] S1. Insert the boring bar 1 into the stern tube 2, fix the head fixing bracket 4 and the tail fixing bracket 3 with the hull as a whole, and install the intermediate support bracket 5 in the stern tube 2 for auxiliary support And fixed boring row boring bar 1.

[0029] S2. Use the inner diameter micrometer 6 to measure the distance between the boring bar 1 and the stern tube 2 at the positions of the head fixing bracket 4 and the tail fixing bracket 3 of the boring bar 1, and adjust the radial adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com