Surface printing equipment for machining in textile industry

A technology of mechanical processing and textile industry, applied in the field of surface printing equipment for mechanical processing in the textile industry, to achieve the effect of preventing wrinkling, cleaning the surface of the fabric, and good color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

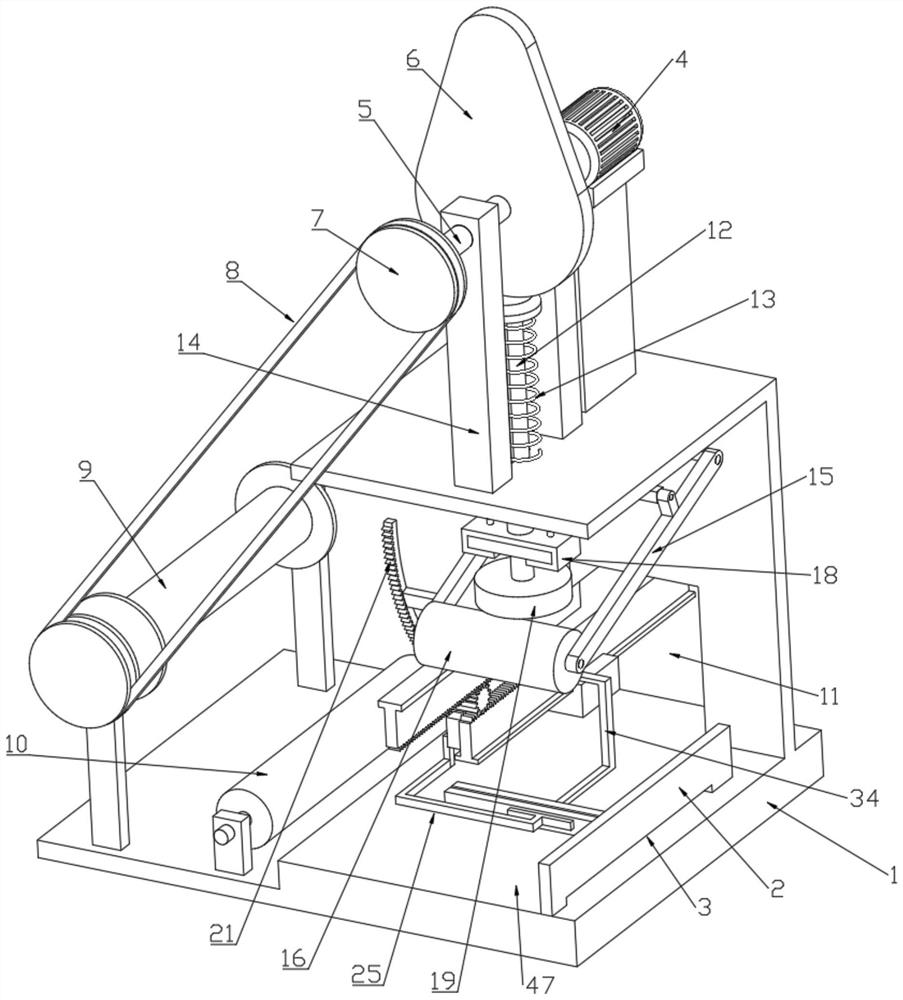

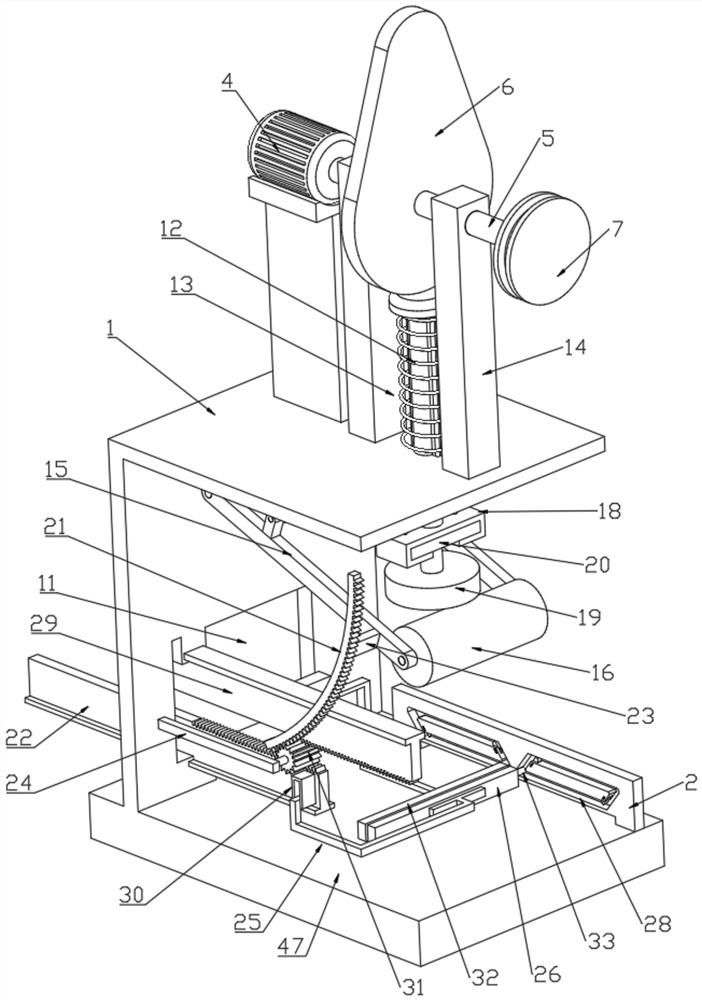

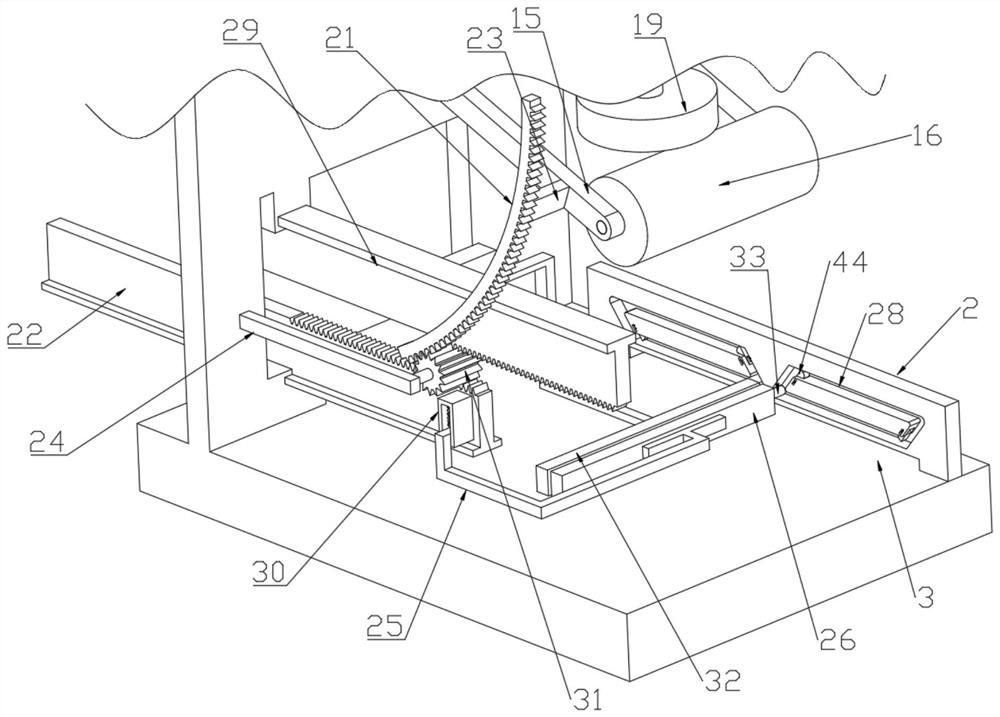

[0032] see figure 1 , figure 2 and Figure 11 , a kind of surface printing equipment for mechanical processing of the textile industry, comprising a machine tool 1, a printing device is arranged on the machine tool 1, the printing device includes a motor 4 fixedly connected to the machine tool 1 through a boss, the output shaft of the motor 4 is fixedly connected with a rotating rod 5. The upper surface of the machine tool 1 is fixedly connected with the support rod 14 which is rotationally connected with the rotary rod 5. The part of the rotary rod 5 located between the support rod 14 and the motor 4 is fixedly connected with the cam 6. The upper surface of the machine tool 1 is provided with a The pressure rod 12 that can slide up and down along the through hole, the upper end of the pressure rod 12 is against the arc-shaped contour surface of the cam 6, the part of the outer wall of the pressure rod 12 located on the upper surface of the machine tool 1 is provided with a ...

Embodiment 2

[0049] see Figure 9 and Figure 10 , in this embodiment, other structures remain unchanged, and the present invention also provides another structural form of the oil replenishment roller 16, further, an oil replenishment rod 51 is arranged inside the oil replenishment roller 16 along its length direction, and the oil replenishment rod The two ends of 51 expose the oil supply roller 16 and are rotatably connected on the fixed rod one 15. The oil replenishment rod 51 passes through the fixed rod one 15 and is connected with the oil box 49 arranged on the side of the fixed rod one 15. The oil box 49 An oil replenishment port 50 is arranged at the upper end, and a threaded cover is arranged on the oil replenishment port 50. The oil replenishment roller 16 is made of sponge material, and the oil replenishment rod 51 is hollow, and a plurality of capillary holes are opened on the wall. Compared with Embodiment 1, oil can be continuously supplied to the oil replenishing rod 51 thr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap