Method for hoisting FPSO flare tower by using floating crane

A torch tower and torch tower pile technology is applied in the field of hoisting FPSO torch towers with floating cranes, which can solve the problems such as difficulty in finding lifting equipment at the wharf, affecting the construction period of the project, etc., so as to reduce construction risks, improve construction accuracy, and accurately position. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

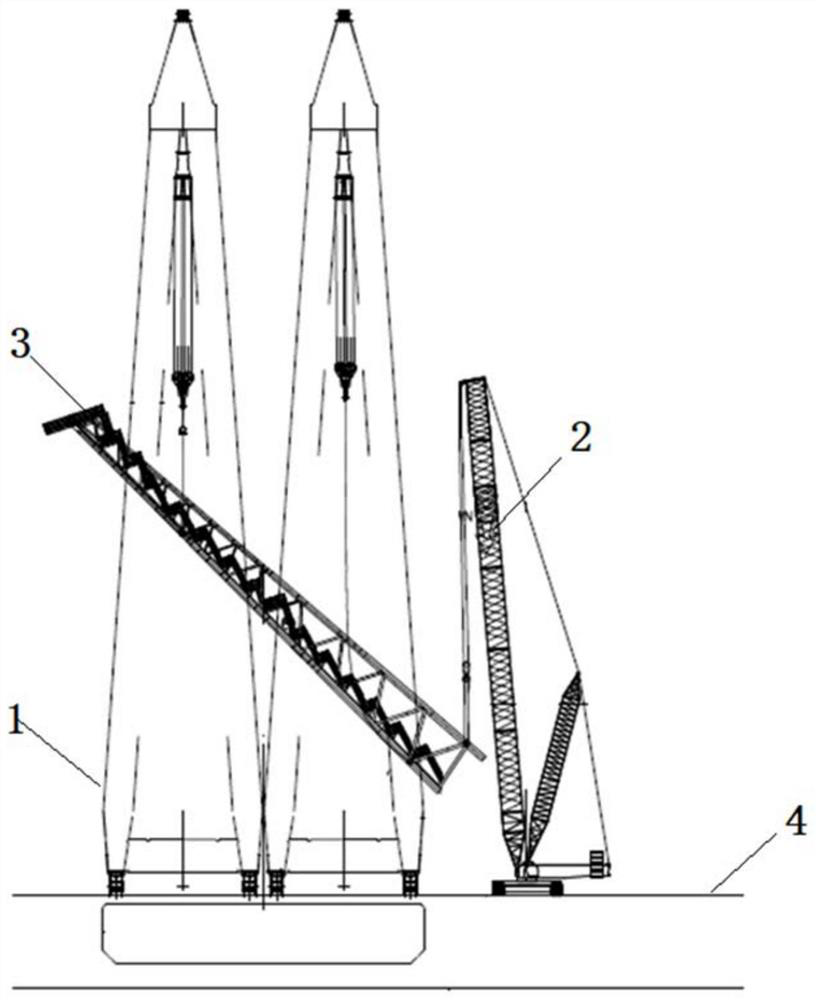

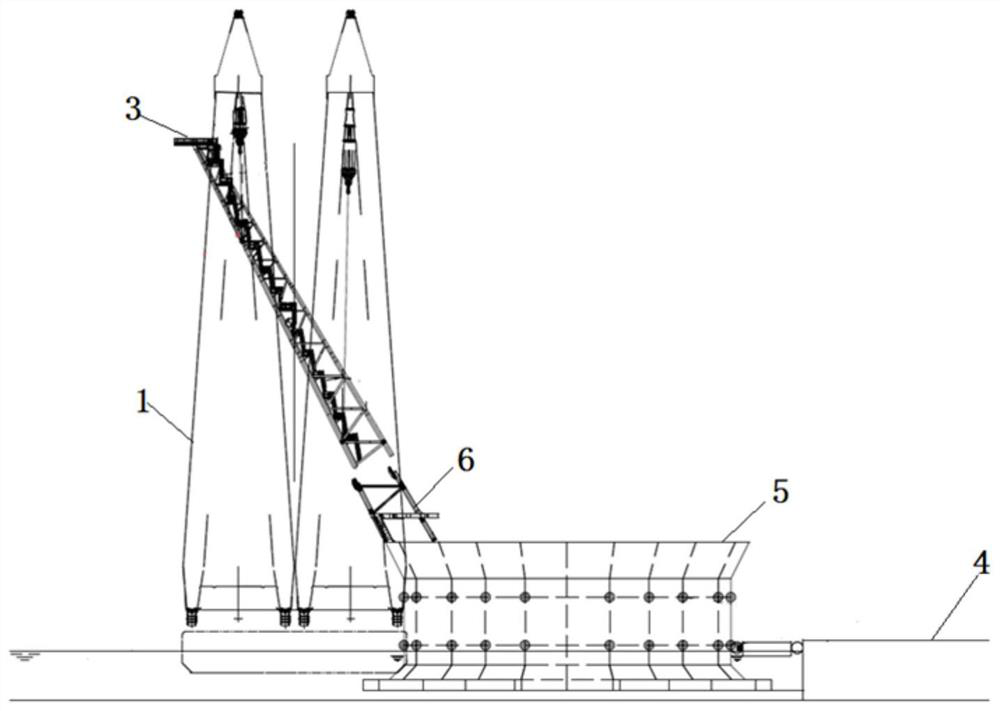

[0026] Examples such as Figure 1 to Figure 4 Shown, the present invention discloses a kind of method that carries out FPSO flare tower hoisting with floating crane, and the concrete implementation of each step is as follows:

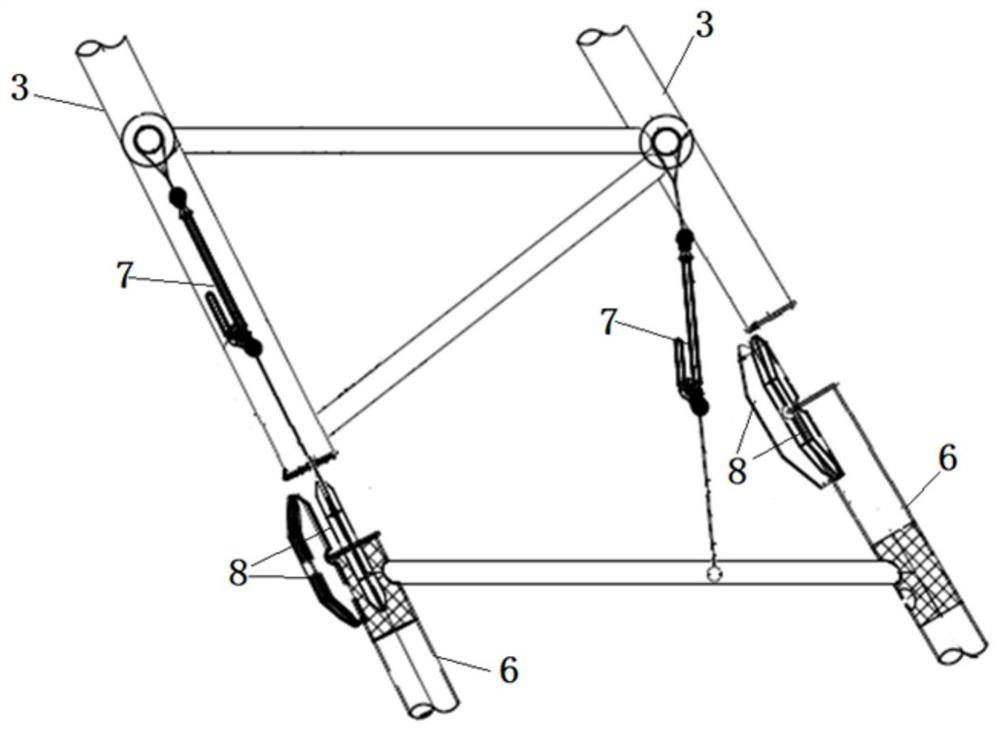

[0027] (1) Prefabricate the guide plate 8 on the support pipe 6 of the base of the flare tower to form a slideway;

[0028] like image 3 Or shown in 4, two guide plates 8 are installed on each support tube 6, and guide plate 8 is positioned at the inboard of support tube 6 on the flare tower base, and two guide plates 8 and support tube 6 encircle into slideway. When the legs of the flare tower 3 enter the slideway, they play a restrictive role in loweri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com