Single-sided protective film adhesive tape as well as preparation method and application thereof

A protective film, single-sided technology, applied in the direction of adhesives, pressure-sensitive films/sheets, film/sheet-like adhesives, etc., can solve problems such as impact, difficult to polish thoroughly, and affect the appearance of the product, to meet the stability, good fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the high-strength wear-resistant single-sided protective film tape comprises the following steps:

[0029] (1) Mix special acrylic pressure-sensitive adhesive resin, curing agent and solvent together, and stir for a certain period of time to obtain a protective film adhesive;

[0030] (2) Apply the protective film adhesive to the release surface of the release film, and dry at 125°C for 10 minutes;

[0031] (3) After drying, transfer the release film coated with UV-viscosity-reducing adhesive to the surface of the corona-treated substrate, and ripen for 48-72h at a temperature of 50°C to obtain the high-strength Stick and peel off the single-sided protective film tape.

[0032] The technological method of described curved surface grinding, comprises the following steps:

[0033] (1) Die-cut the single-sided protective film tape into a 15mm*1mm arc-shaped hole structure.

[0034] (2) Remove the centrifugal film, stick the single-sided tape on...

specific example 1

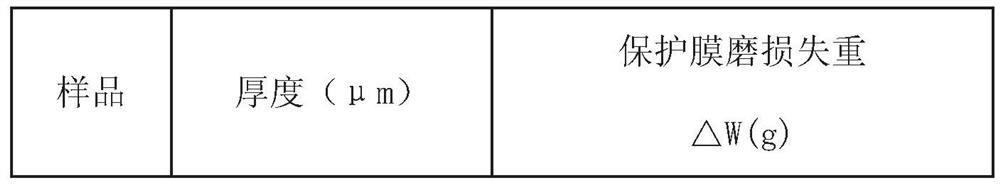

[0037] Specific example 1 The present invention provides several protective film substrates, including polyetheretherketone substrate (PEEK), polyethylene terephthalate (PET), polytetrafluoroethylene (PTFE), thermoplastic polyurethane elastomer rubber (TPU), the substrate thickness is 50 microns. Use sponge sandpaper to apply a pressure of 500g, and perform a single 15s, 3-cycle grinding test on the protective film to observe the weight loss of the protective film.

[0038]

[0039]

[0040] It can be seen from the table that different polymer material protective films have different wear resistance properties. After multiple cycles of grinding, it was found that PEEK had the best grinding performance, and the protective film was not damaged after grinding, while PET and PTFE The three polymer substrates of TPU and TPU all have different degrees of grinding damage.

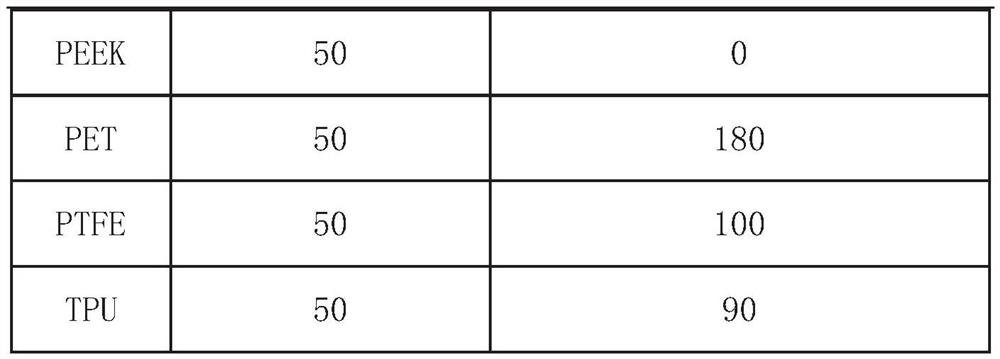

[0041] Concrete example 2: In order to meet the grinding requirements of different modulus products, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com