Construction method for skylight fixing frame

A construction method and fixing frame technology, which are applied to skylights/domes, building materials processing, roofing, etc., can solve problems such as affecting the normal use of the roofing system, damage to the roofing system, etc. The effect of mitigating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

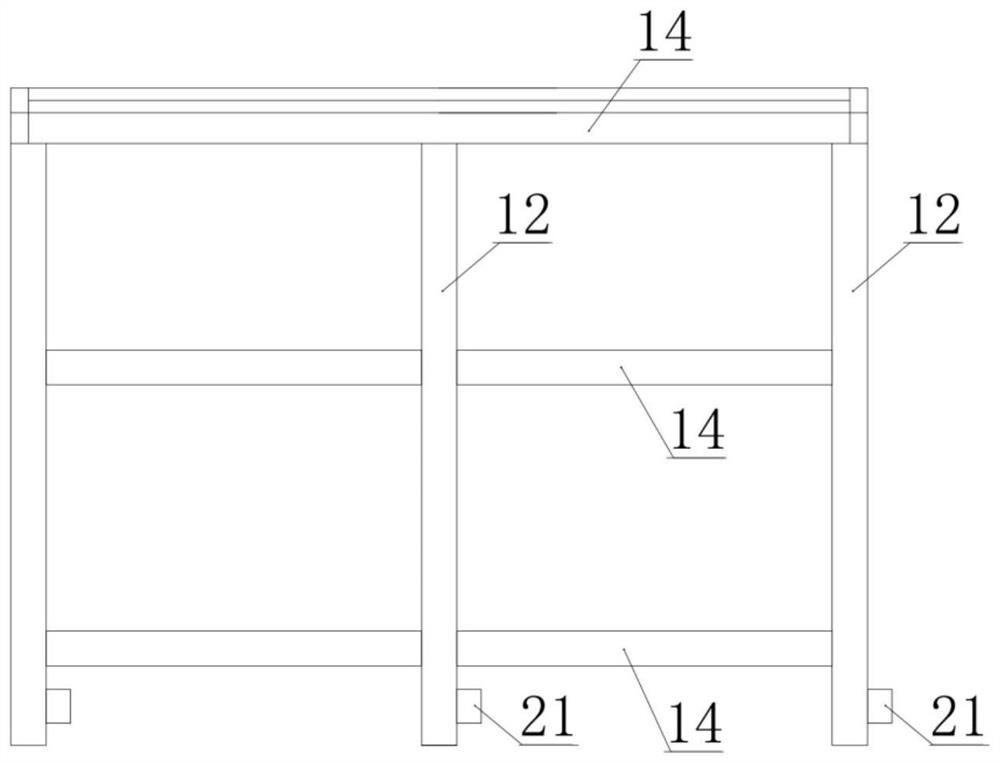

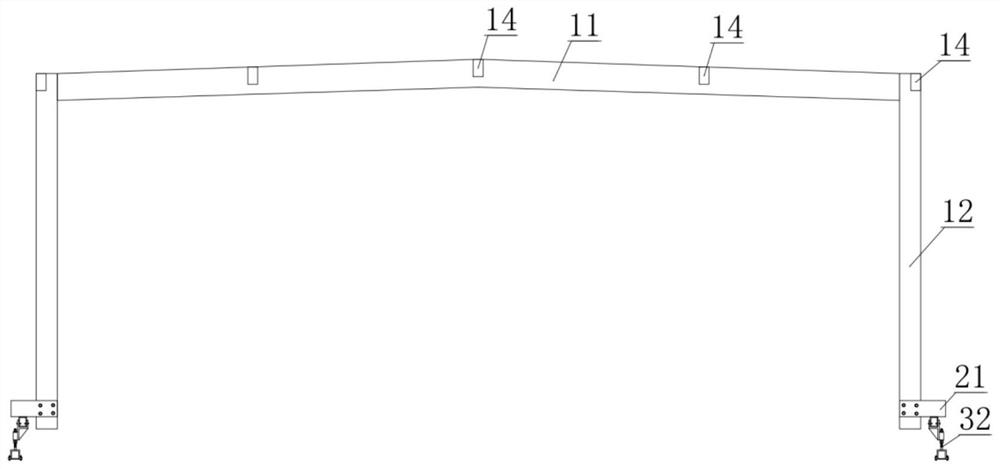

[0032] A construction method for a sunroof fixing frame, such as Figures 1 to 3 shown, including the following steps:

[0033] (S1) Assemble the steel on the ground to obtain gantry segments. Each gantry segment contains at least two gantry frames. The gantry frames include the top transverse keel 11 and the longitudinal keels 12 on both sides. Connected by a group of connecting keels 14;

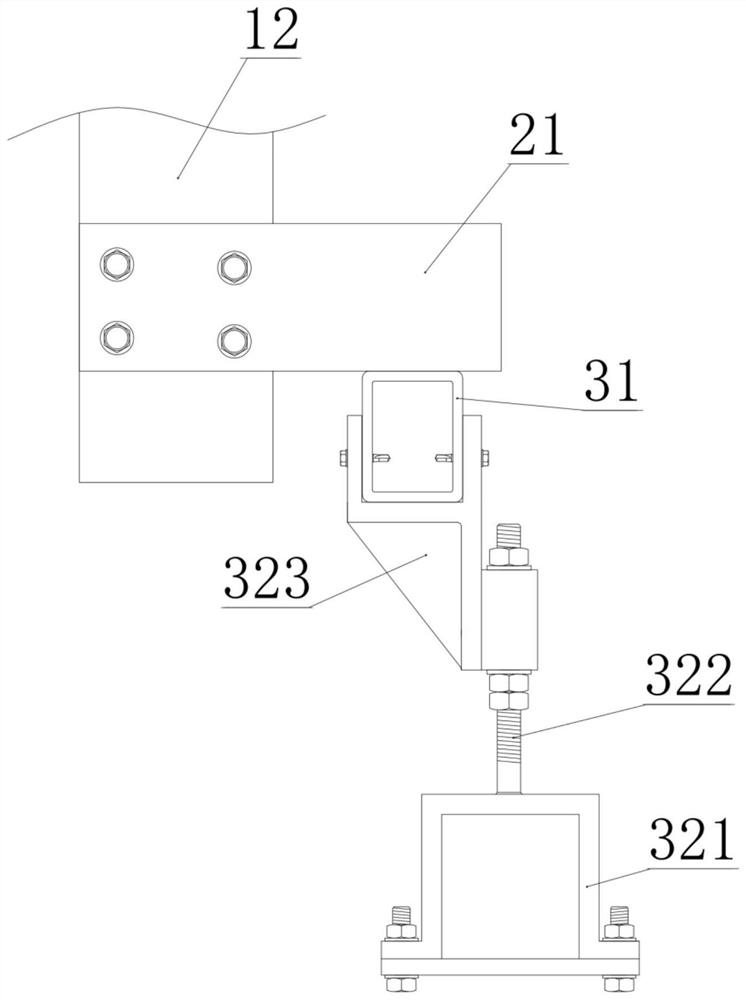

[0034] (S2) Install lugs 21 on the bottom of both sides of the gantry frame, and the lugs 21 are installed on the longitudinal keel 12;

[0035] (S3) Set up a pair of parallel slide rails 31 on the roof according to the installation position of the skylight fixing frame;

[0036] (S4) hoisting the gantry segments to the roof one by one so that the lugs 21 are pressed against the slide rails 31;

[0037] (S5) Use the pulling device to pull the gantry segments to the installation position one by one;

[0038] (S6) Fix the gantry segments on the roof, specifically fix the anchor points at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com