Ultrahigh working layer involute water gap diamond-impregnated drill bit and preparation method thereof

A technology of impregnated diamond and working layer, applied in the fields of oil and gas drilling and geological drilling, can solve the problems of false circulation of mud and high requirement of bit pumping capacity, so as to reduce the tripping operation, improve the powder carrying capacity, and reduce the repeated crushing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

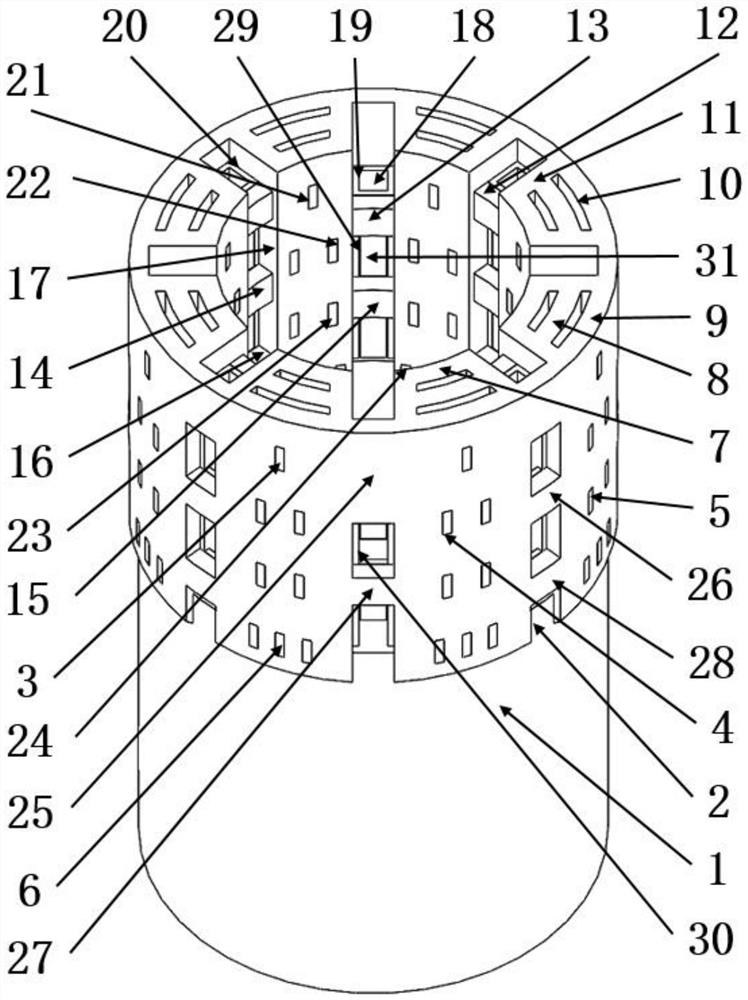

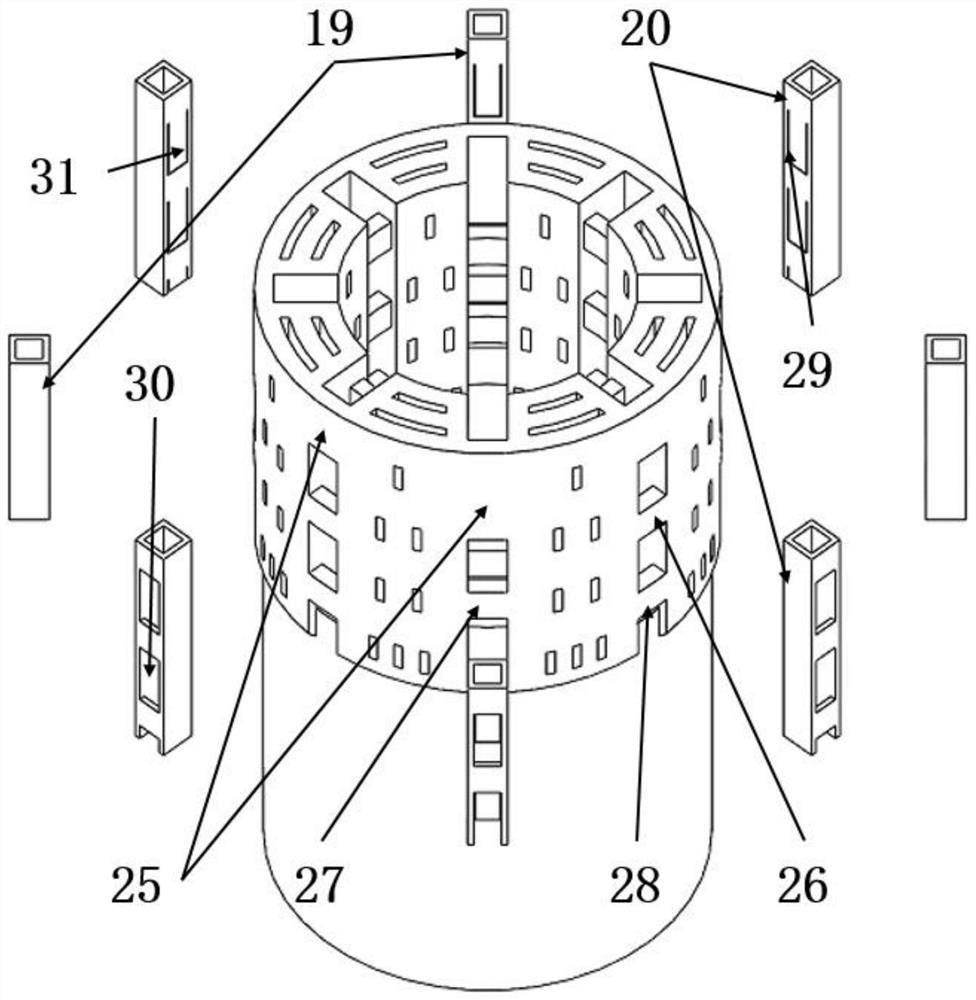

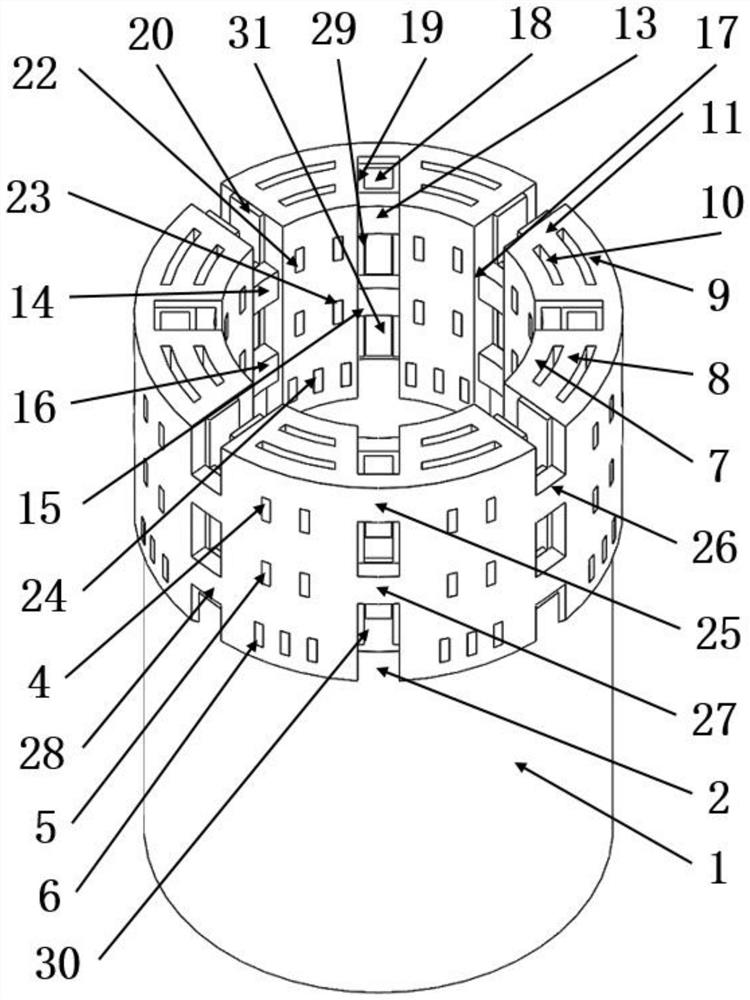

[0039] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0040] Super-high working layer involute nozzle impregnated diamond drill bit, including steel body 1 and the drill bit working part connected to the upper end of steel body 1;

[0041] A plurality of first mud-resistance structures 19 and a plurality of second mud-resistance structures 20 are vertically and alternately distributed in the nozzle of the working part of the drill bit;

[0042] The first mud-resistance structure 19 and the second mud-resistance structure 20 are hollow cubes, and the first mud-resistance structure 19 and the second mud-resistance structure 20 hollow inside form the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com