Nano-magnetic fluid clearance sealing high-speed hydraulic cylinder

A nano-magnetic fluid and hydraulic cylinder technology, applied in the direction of fluid pressure actuation devices, etc., can solve the problems of fatigue and hydraulic cylinders that are difficult to meet the sealing and lubricity at the same time, so as to reduce interference, realize self-adaptive regulation, and avoid dry friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

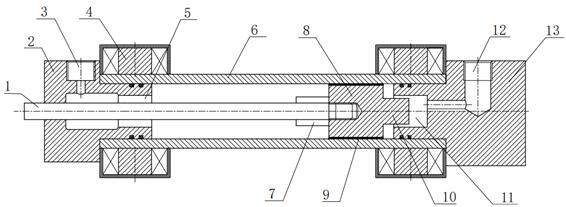

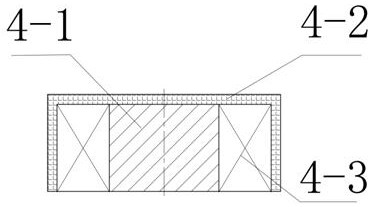

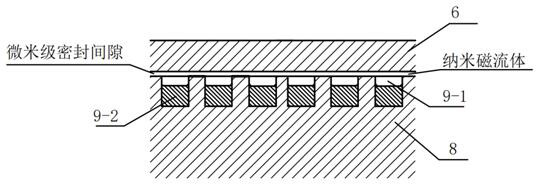

[0044] Such as figure 1 As shown, a nano-magnetic fluid gap seal high-speed hydraulic cylinder includes a piston rod 1, a cylinder head with a rod cavity 2, an oil port with a rod cavity 3, an electromagnet 4, a buffer cavity with a rod cavity 5, a cylinder barrel 6, and a rod Cavity buffer head 7, piston 8, micromagnetic array functional surface 9, rodless cavity buffer head 10, rodless cavity buffer cavity 11, rodless cavity oil port 12, and non-sensing cavity cylinder head 13.

[0045] The rod chamber cylinder head 2 is provided with a rod chamber oil port 3 and a rod chamber buffer chamber 5 communicating with the rod chamber oil port 3 , and the rod chamber buffer chamber 5 is located in the middle of the rod chamber cylinder head 2 .

[0046] One end of the piston 8 is provided with a buffer head 7 with a rod chamber, and the other end is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com