Ultrahigh-precision optical fiber gyroscope structure

A fiber optic gyroscope, high-precision technology, applied in Sagnac effect gyroscopes, gyroscopes/steering sensing equipment, instruments, etc., can solve problems such as certain gaps, achieve stable and uniform temperature, improve measurement accuracy, and low coercivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

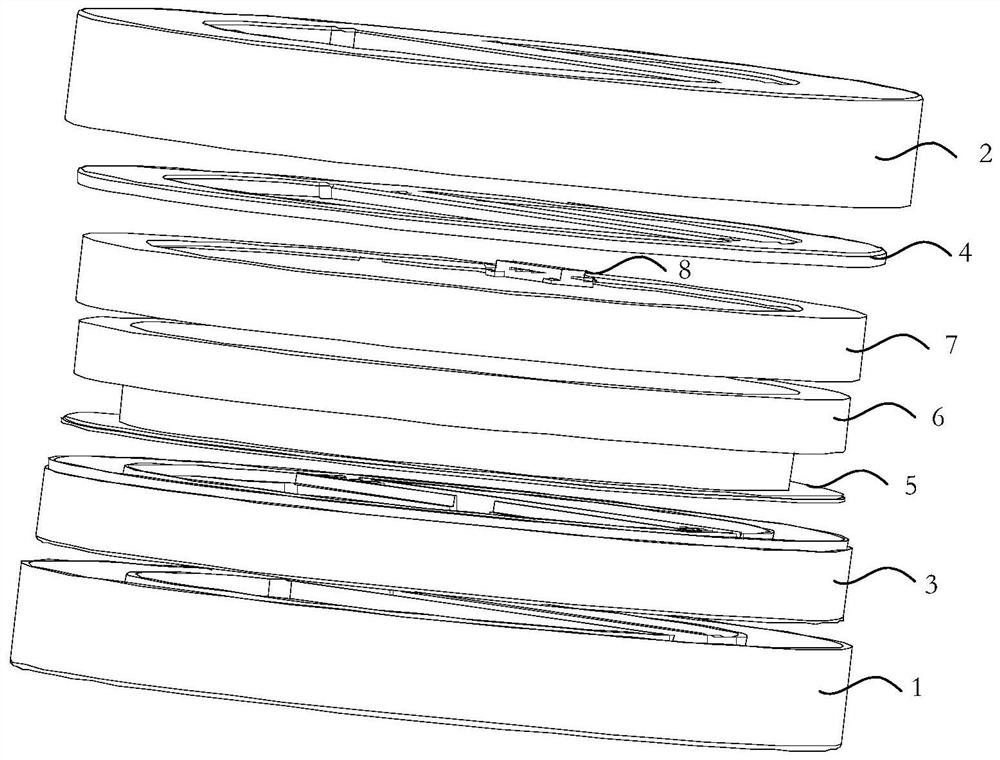

[0055] Such as figure 1 Shown is a schematic diagram of the structure of the fiber optic gyroscope of the present invention, including a mounting flange 1, an outer cover 2, a mounting base 3, a mounting cover 4, a fiber ring base 5, a fiber ring coil 6, a fiber ring inner cover 7, and a Y waveguide 8 .

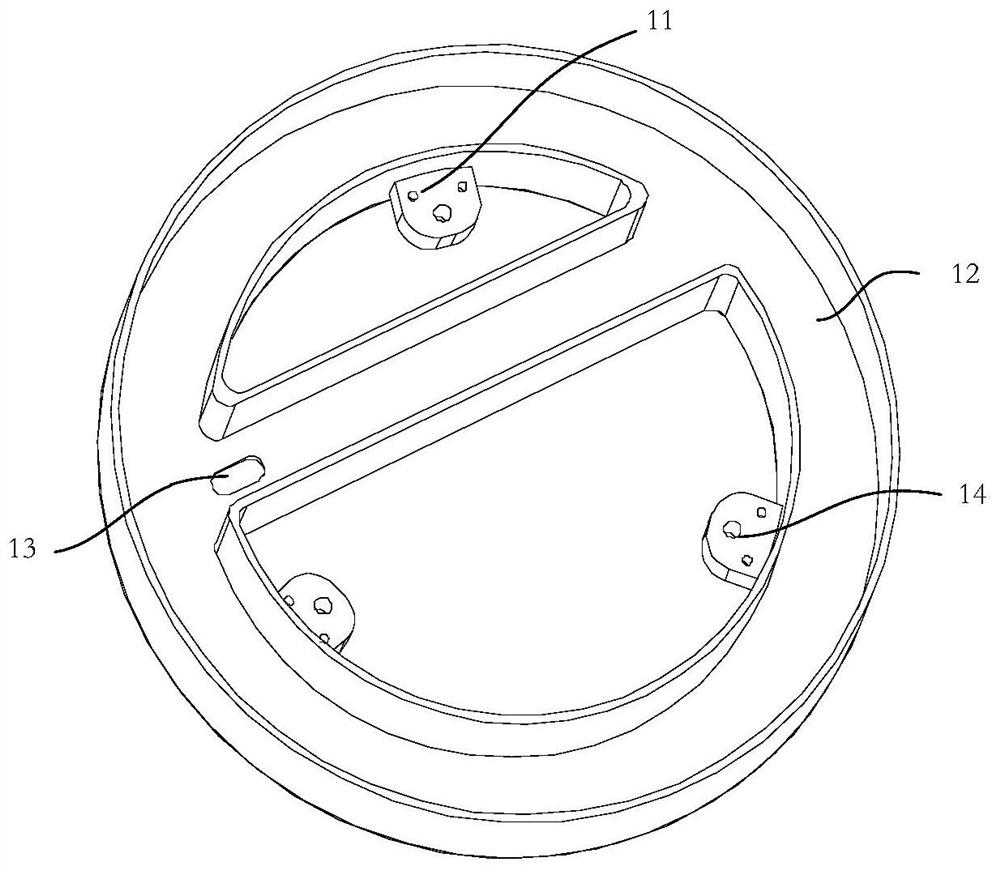

[0056] Such as figure 2 Shown is a schematic diagram of the structure of the mounting flange 1 of the present invention. The mounting flange 1 acts as a load bearing and is an annular cylindrical structure with a bridge lap design in the middle, corresponding to the ring groove of the flange and the linear groove of the flange respectively, with The sufficiently high structural natural frequency reduces the influence of installation errors caused by the deformation of structural parts. The wall thickness of the mounting flange 1 is 1-1.5 mm, which is 1.5 mm in this embodiment. There are 3 mounting lugs 11 with 6 threaded holes in total, which are used to install the cover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com