Polyethylene fiber-reinforced zeolite-fly ash-based geopolymer with ultra-high molecular weight and preparation method of polyethylene fiber-reinforced zeolite-fly ash-based geopolymer

A technology of polyethylene fiber and ultra-high molecular weight, which is applied in the field of materials science to achieve the effect of low cost and solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

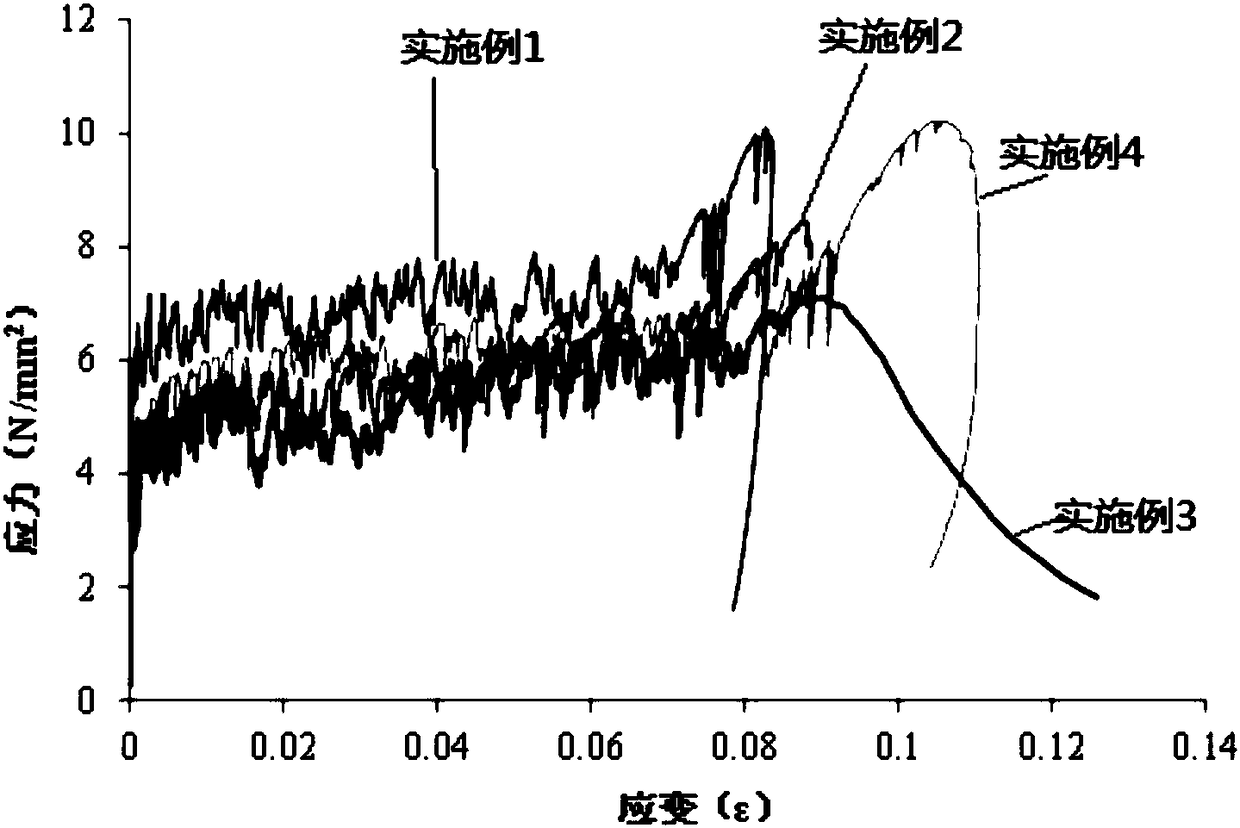

Embodiment 1

[0039] Low-calcium fly ash: 542 parts, high-calcium fly ash: 136 parts, quartz sand: 203 parts, sodium silicate: 173 parts, sodium hydroxide: 38 parts, water: 160 parts, ultra-high molecular weight polyethylene fiber: 14 parts, zeolite: 0 parts.

[0040] Step 1, take by weighing 542 parts of I-level low-calcium fly ash, 136 parts of I-level high-calcium fly ash, 203 parts of quartz sand, and 0 part of zeolite and join in the stirring pot, and the revolution is 57~67r / min, and the rotation is Stir dry at a speed of 135-145r / min for 3 minutes until the mixture is evenly obtained;

[0041] Step 2, take by weighing 160 parts of water, 38 parts of purity be 99% sodium hydroxide, 173 parts of sodium silicate of 3.3 moulds, mix and stir in the beaker and make alkali activator;

[0042] Step 3, add the alkali activator prepared in step 3 into the stirring pot of step 2, and stir for 5 minutes at a speed of 115-135 r / min in revolution and 275-295 r / min in rotation, so that the alkali ...

Embodiment 2

[0047] Low calcium fly ash: 526 parts, high calcium fly ash: 132 parts, quartz sand: 203 parts, sodium silicate: 173 parts, sodium hydroxide: 38 parts, water: 160 parts, fiber: 14 parts, zeolite: 20 servings.

[0048] Step 1, weigh 526 parts of I-grade low-calcium fly ash, 132 parts of I-grade high-calcium fly ash, 203 parts of quartz sand, and 20 parts of zeolite and add them to the stirring pot. Stir dry at a speed of 135-145r / min for 3 minutes until the mixture is evenly obtained;

[0049] Step 2, take by weighing 160 parts of water, 38 parts of purity be 99% sodium hydroxide, 173 parts of sodium silicate of 3.3 moulds, mix and stir in the beaker and make alkali activator;

[0050] Step 3, add the alkali activator prepared in step 3 into the stirring pot of step 2, and stir for 5 minutes at a speed of 115-135 r / min in revolution and 275-295 r / min in rotation, so that the alkali activator and the mixture One is mixed to obtain mixture two;

[0051]Step 4, add 14 parts of ...

Embodiment 3

[0056] Low calcium fly ash: 509 parts, high calcium fly ash: 128 parts, quartz sand: 203 parts, sodium silicate: 173 parts, sodium hydroxide: 38 parts, water: 160 parts, fiber: 14 parts, zeolite: 41 copies.

[0057] Step 1, weigh 509 parts of I-level low-calcium fly ash, 128 parts of I-level high-calcium fly ash, 203 parts of quartz sand, and 41 parts of zeolite and add them to the stirring pot. Stir dry at a speed of 135-145r / min for 3 minutes until the mixture is evenly obtained;

[0058] Step 2, take by weighing 160 parts of water, 38 parts of purity be 99% sodium hydroxide, 173 parts of sodium silicate of 3.3 moulds, mix and stir in the beaker and make alkali activator;

[0059] Step 3, add the alkali activator prepared in step 3 into the stirring pot of step 2, and stir for 5 minutes at a speed of 115-135 r / min in revolution and 275-295 r / min in rotation, so that the alkali activator and the mixture One is mixed to obtain mixture two;

[0060] Step 4, add 14 parts of u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com