Multi-station test equipment

A test equipment and multi-station technology, applied in the field of optical testing, can solve the problems of occupation, large space, large structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

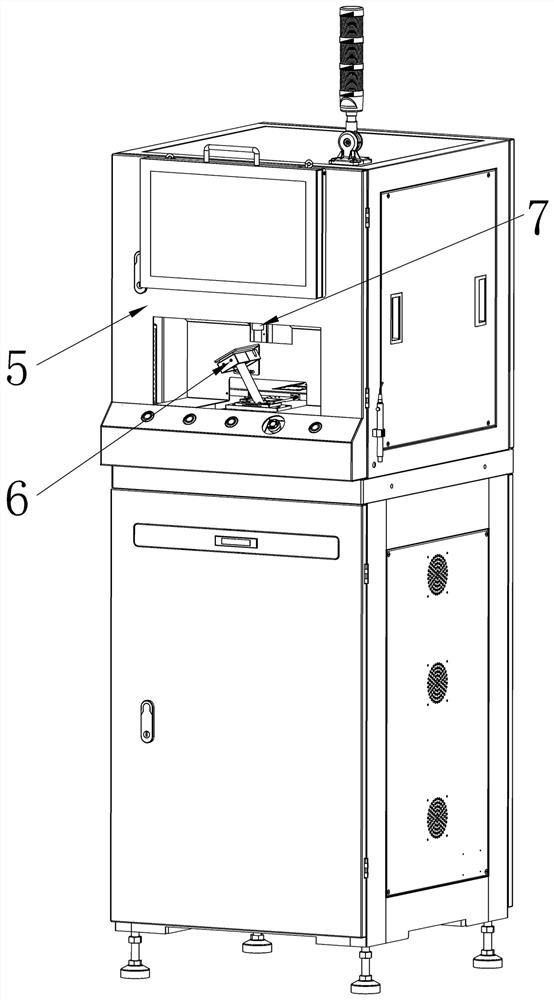

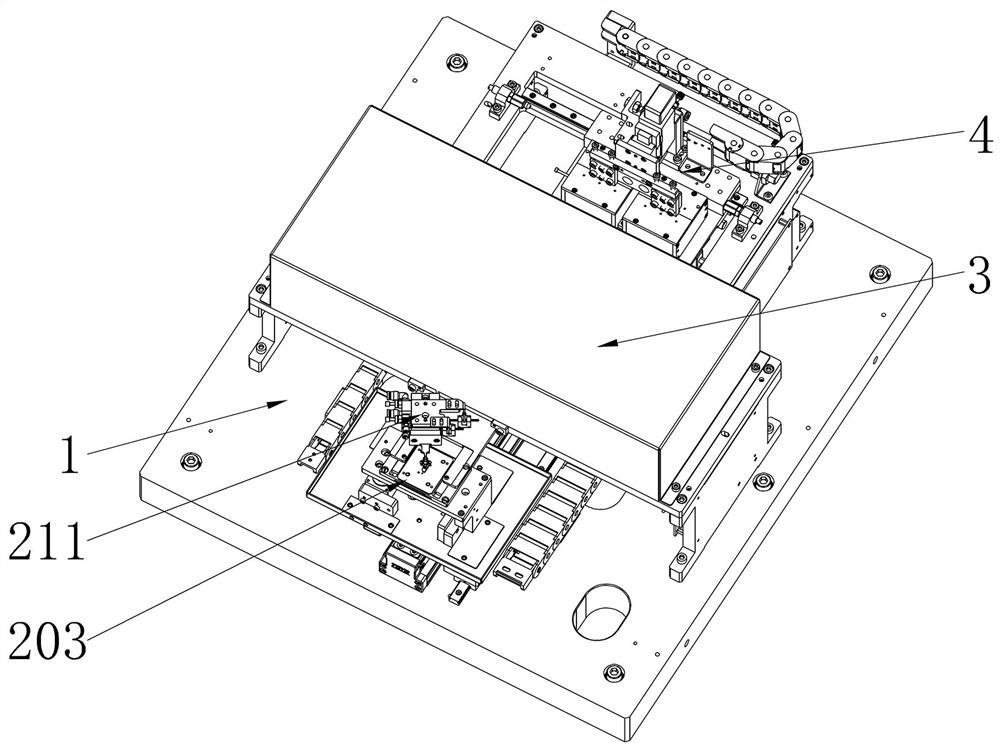

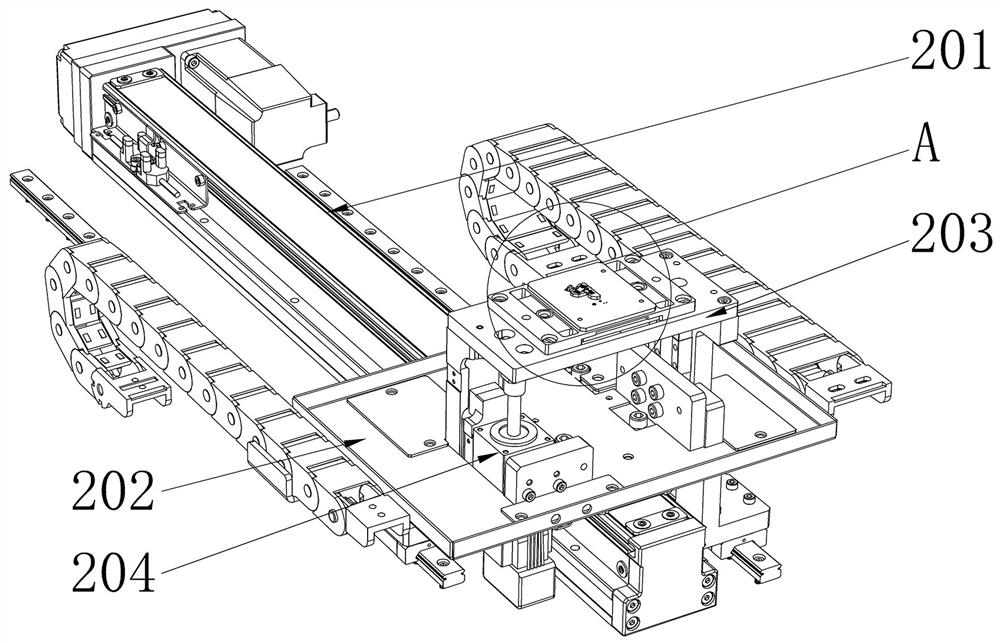

[0027] like Figure 1 to 8 , In the present embodiment, the present invention comprises a base 1, a mobile carrier module 2, module 3, and the black test cards dual card test module 4, the module 2 comprises a carrier moving Y-axis drive mechanism 201 and a lifter disposed on the Y-axis driving mechanism 201 of the carrier assembly, the black card 3 and the test modules test dual card module 4 is disposed above the carrier 2 and moved along the module longitudinal direction of the Y-axis driving mechanism 201 are sequentially disposed, the black test card module 3 comprises a first test station along the longitudinal direction of the Y axis are sequentially arranged second test station 301 and 302, the second test station gray card test assembly is provided with a position on the optical window 302, the dual-SIM test module 4 includes an X-axis drive mechanism, and a Z-axis driving mechanism 401 is disposed parallel to the Z-axis driving mechanism 401 and the supplementary card tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com