Appearance detection equipment

Appearance inspection and equipment technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of unstable production process, high labor cost, easy loss of new workers, and achieve the resolution of abnormal quality and detection efficiency. High and stable production process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

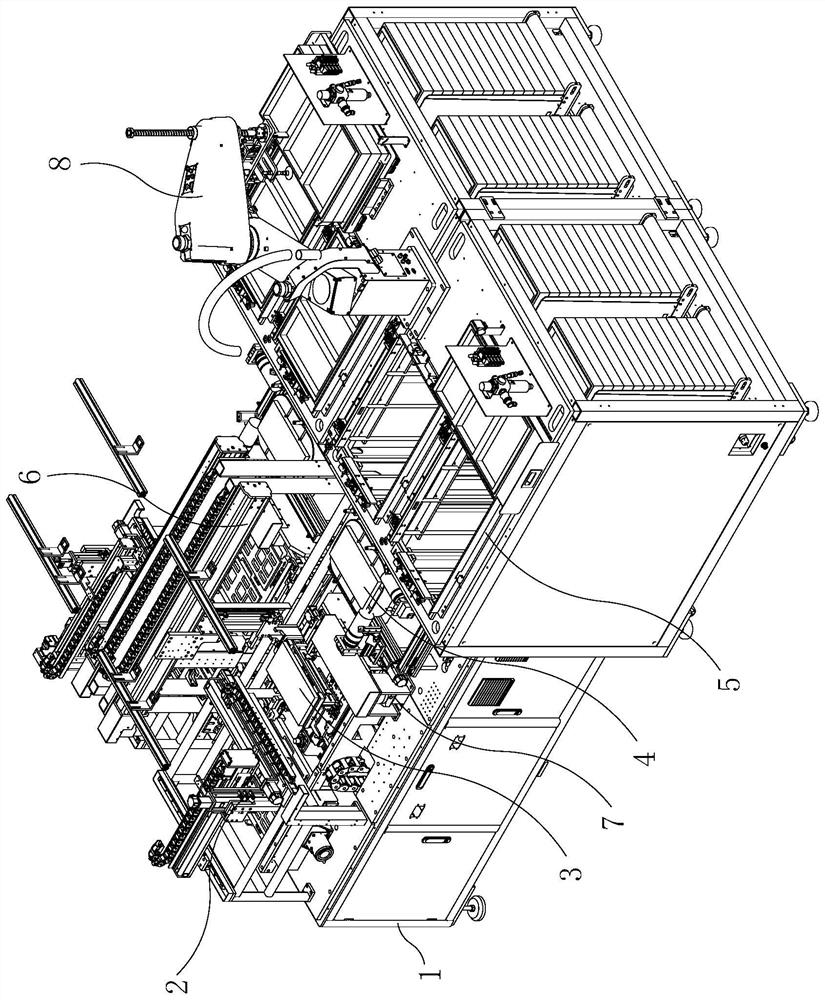

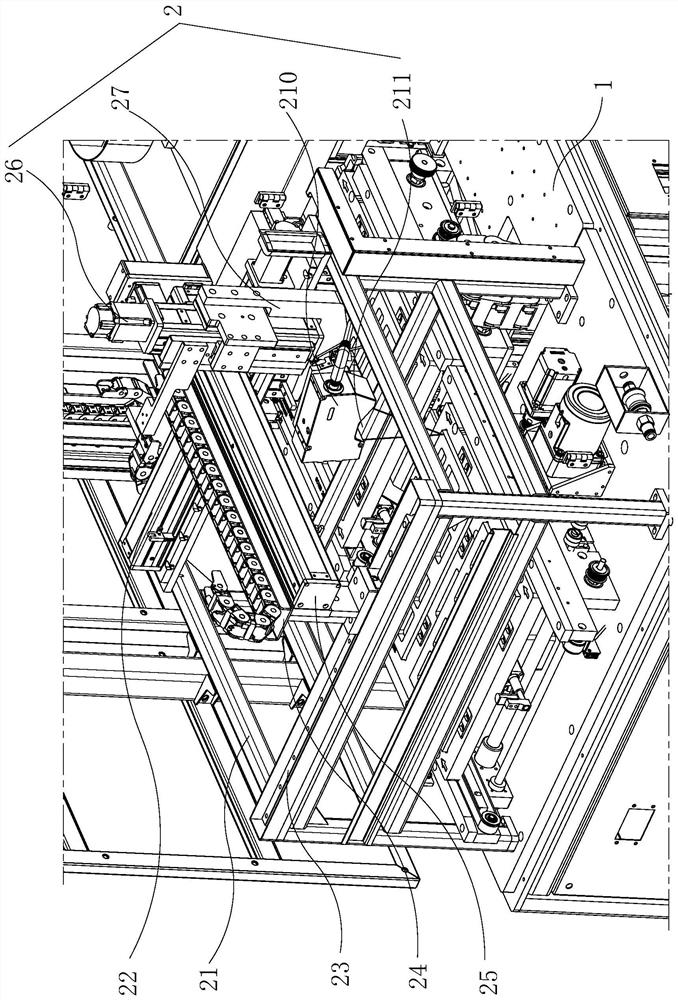

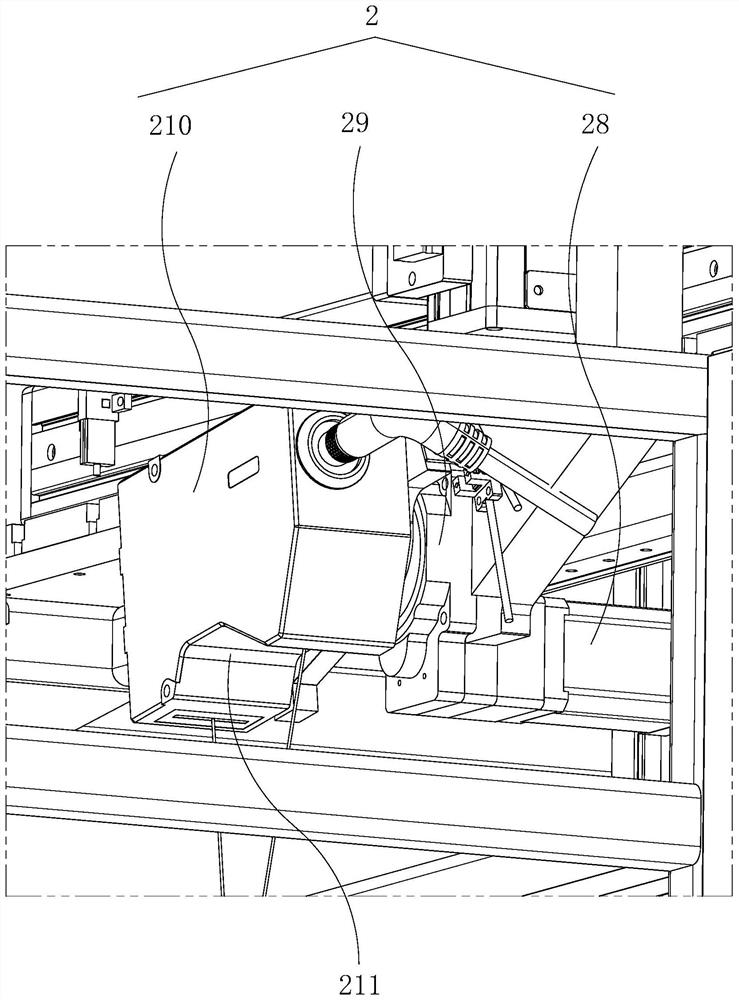

[0045] Such as figure 1 As shown, the present invention is an appearance inspection device, including a machine platform 1, a back detection mechanism 2, a front detection mechanism 3, a side detection mechanism 4, a receiving mechanism 5, a two-axis feeding and transferring mechanism 6, a transmission mechanism 7, Receiving manipulator 8.

[0046] The back detection mechanism 2, the front detection mechanism 3, and the side detection mechanism 4 are all installed on the machine platform 1, the receiving mechanism 5 is installed on one side of the machine platform 1 and is adjacent to the side detection mechanism 4, and the transmission mechanism 7 is installed on the machine platform 1. The machine 1 runs between the back detection mechanism 2 and the front detection mechanism 3, and the two-axis feeding and transferring mechanism 6 is installed on the machine 1 and runs between the front detection mechanism 3 and the side detection mechanism 4. The manipulator 8 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com