Cooling system

A technology of cooling system and cooling fluid, which is applied in the direction of engine cooling, heating/cooling equipment, power plant cooling combination arrangement, etc., and can solve problems such as difficult balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

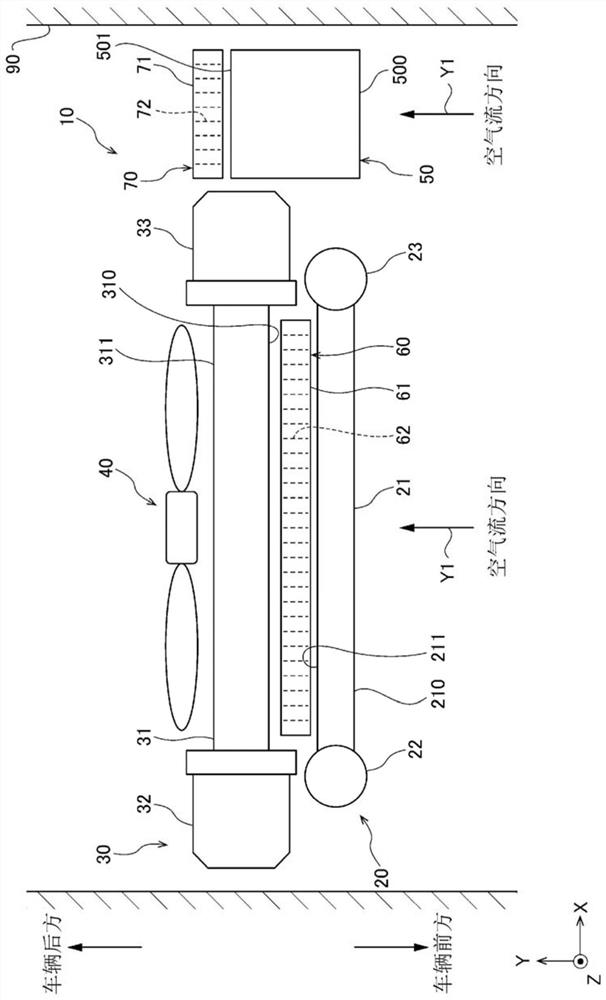

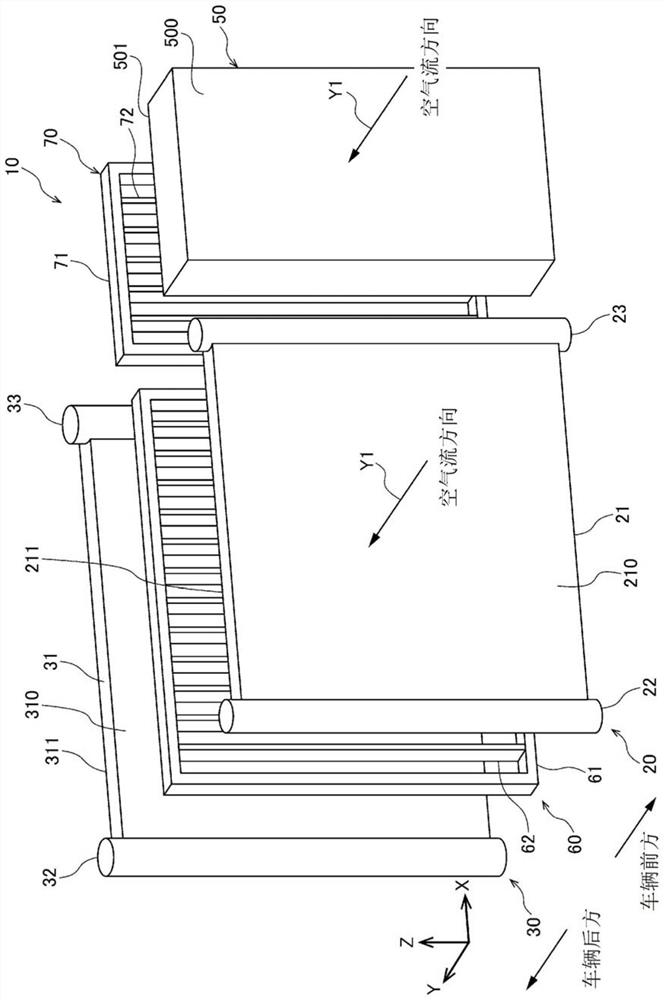

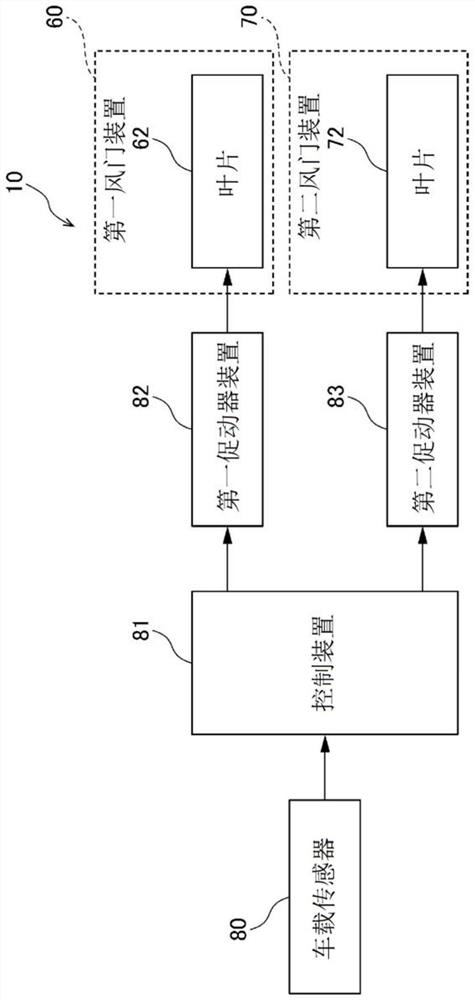

[0028] first of all, yes figure 1 The cooling system 10 of the first embodiment shown will be described. Cooling system 10 is mounted on a vehicle. The cooling system 10 includes a condenser 20 , a radiator 30 , a fan unit 40 , an intercooler 50 , a first damper unit 60 , and a second damper unit 70 . These elements are arranged in the air passage 90 in the engine compartment of the vehicle. In the air passage 90 , air introduced from the grille opening of the vehicle, that is, traveling wind flows in a direction indicated by an arrow Y1 . In the present embodiment, the condenser 20 and the radiator 30 correspond to a specific heat exchange unit, and the intercooler 50 corresponds to a heat exchange unit different from the specific heat exchange unit.

[0029] Hereinafter, for the sake of convenience, the direction indicated by the arrow Y1 is referred to as "airflow direction Y1". In addition, the air introduced from the grill opening is called "external air". The direct...

no. 2 approach >

[0067] Next, the cooling system 10 of the second embodiment will be described. Hereinafter, the description will focus on differences from the cooling system 10 of the first embodiment.

[0068] Such as Figure 8As shown, the cooling system 10 of the present embodiment is different from the cooling system 10 of the first embodiment in that the intercooler 50 and the second damper device 70 are not included. Moreover, the core part 31 of the heat sink 30 of this embodiment is divided into the 1st core part 31a and the 2nd core part 31b. The first core part 31a and the second core part 31b are arranged side by side in a direction perpendicular to the airflow direction Y1. High-temperature cooling water flows inside each tube of the first core portion 31a. High-temperature cooling water is cooling water used for cooling, for example, an engine. In the first core portion 31a, the high-temperature cooling water is cooled by heat exchange between the high-temperature cooling wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com