Integral machining method for Z-shaped reinforcement cage of diaphragm wall

A technology of overall processing and steel cages, applied in the direction of wire processing, building reinforcements, building materials, etc., can solve the problems of difficult operation, complicated process, and existing risks, and achieve simple and clear steps, stable structure, and easy processing and welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

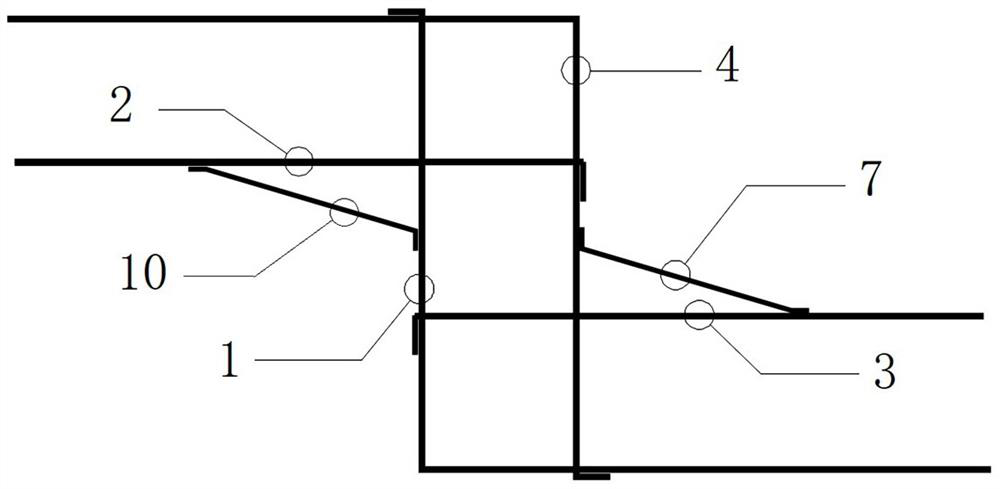

[0031] Embodiment 1: as Figure 1-5 As shown, the present embodiment relates to an overall processing method of a Z-shaped reinforcement cage for a ground connection wall, and the overall processing method includes the following steps:

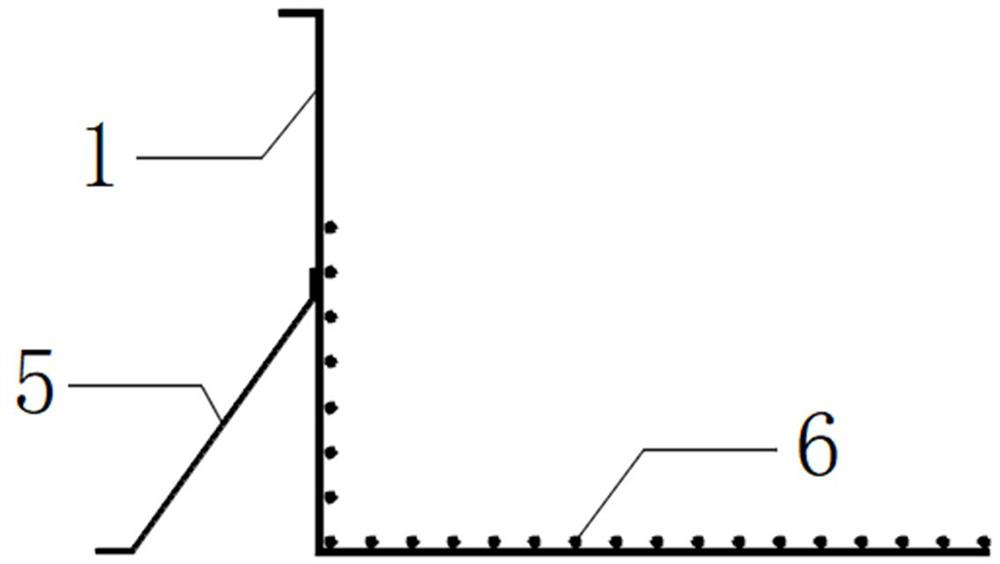

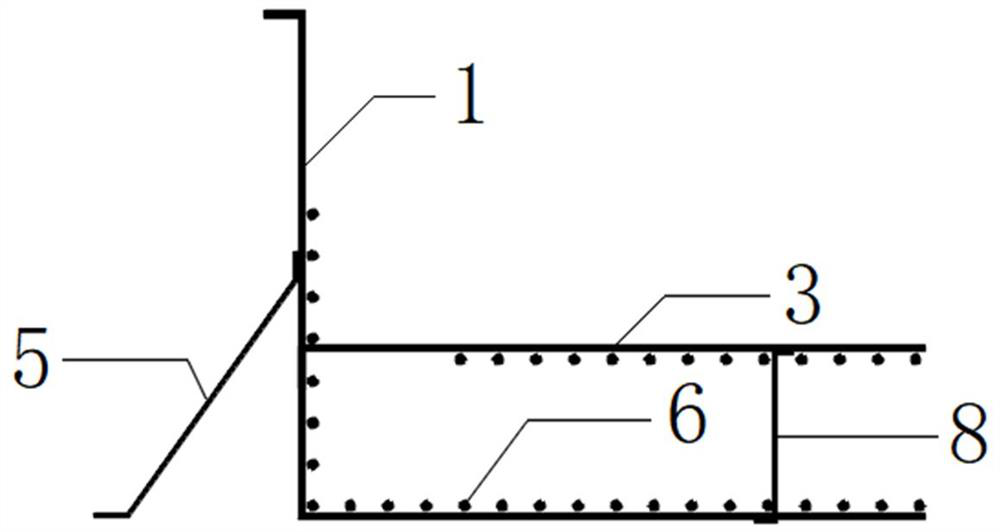

[0032] Step (1): If figure 2 As shown, the lower L-shaped horizontal reinforcement 1 is laid, except for the upper part of the vertical section of the lower L-shaped horizontal reinforcement 1, the longitudinal reinforcement 6 is welded on the inner side of other positions of the lower L-shaped horizontal reinforcement 1 to form the first part of the lower longitudinal truss reinforcement . In addition, the outer side of the vertical section of the lower L-shaped horizontal rib 1 is provided with a first temporary support bracket 5 placed obliquely. One end of the first temporary support bracket 5 is fixed on the ground or the processing platform, and the other end is spot welded to the lower L-shaped horizontal rib 1. Fixed, used to suppor...

Embodiment 2

[0037] Embodiment 2: as Figure 5-7 Shown, a kind of hoisting method of the Z-shaped reinforcement cage of the ground connection wall, the hoisting method comprises the following steps:

[0038] 1. Use the main crane 11, auxiliary crane 12 and auxiliary crane 13 to hoist the Z-shaped reinforcement cage of the ground connection wall, and remove all temporary support brackets. Among them, there are 6 lifting points that can be connected with the main crane 11 on the Z-shaped reinforcement cage of the ground connection wall, which are respectively lifting point a, lifting point b, lifting point c, lifting point d, lifting point e and lifting point Point f, lifting point a and lifting point b are all set at the side of the lower longitudinal truss reinforcement of the Z-shaped reinforcement cage of the ground connection wall, and the lifting point a and lifting point b are respectively located at the lower and upper layers of the lower longitudinal truss reinforcement. Both c and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com