Steel wire driving type variable-rigidity damping vibration attenuation boring bar

A variable stiffness, driving technology, applied in the direction of boring bars, etc., can solve the problems of small cutting parameters, affecting processing efficiency, etc., to achieve the optimal working state and the effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

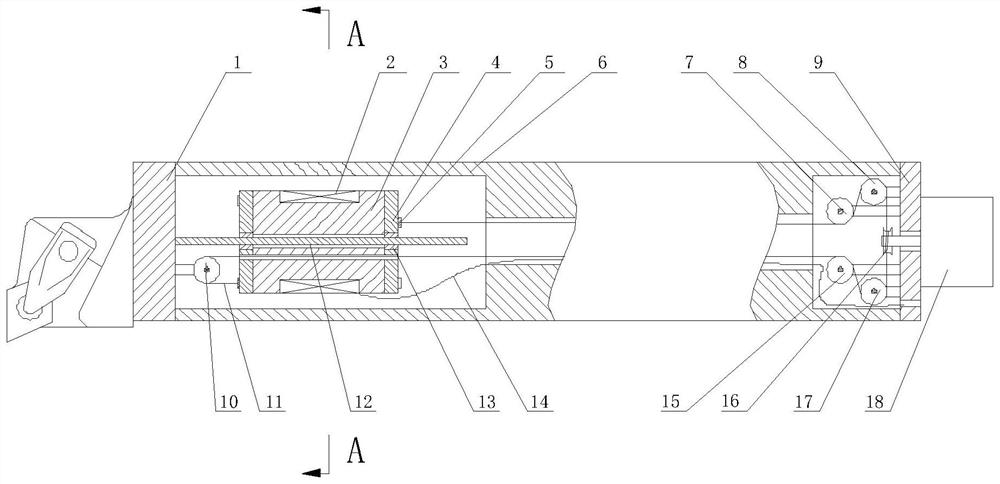

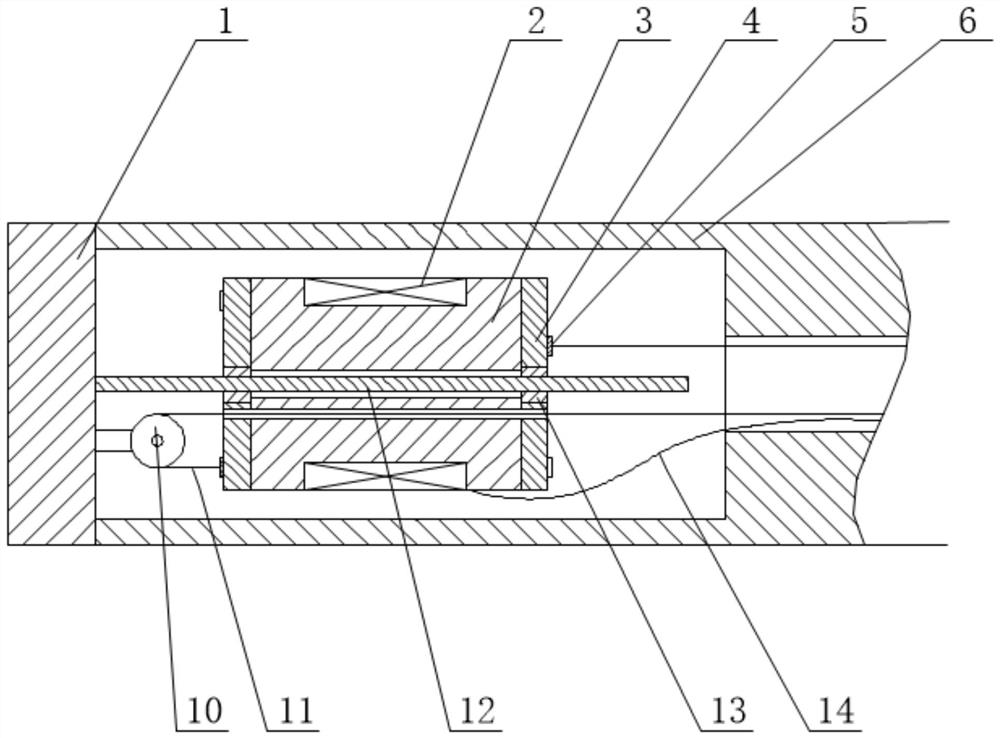

[0033] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, the steel wire driving type variable stiffness damping damping boring bar described in this embodiment,

[0034] Including boring bar 6, damping structure and stiffness adjustment unit;

[0035] The boring bar 6 is provided with a front-end opening cavity, and a vibration-damping structure is arranged in the front-end opening cavity. The vibration-damping structure is used to slow down the micro-movement of the boring bar caused by cutting. There is a gap between the vibration-damping structure and the inner wall of the boring bar 6 Uniform radial clearance; a cutter head connector 1 is arranged at the front opening of the front opening cavity;

[0036] The stiffness adjustment unit realizes the adjustment of the stiffness of the damping structure by adjusting the distance between the slider 3 and the front end of the boring bar 6 .

[0037] The damping structur...

specific Embodiment approach 2

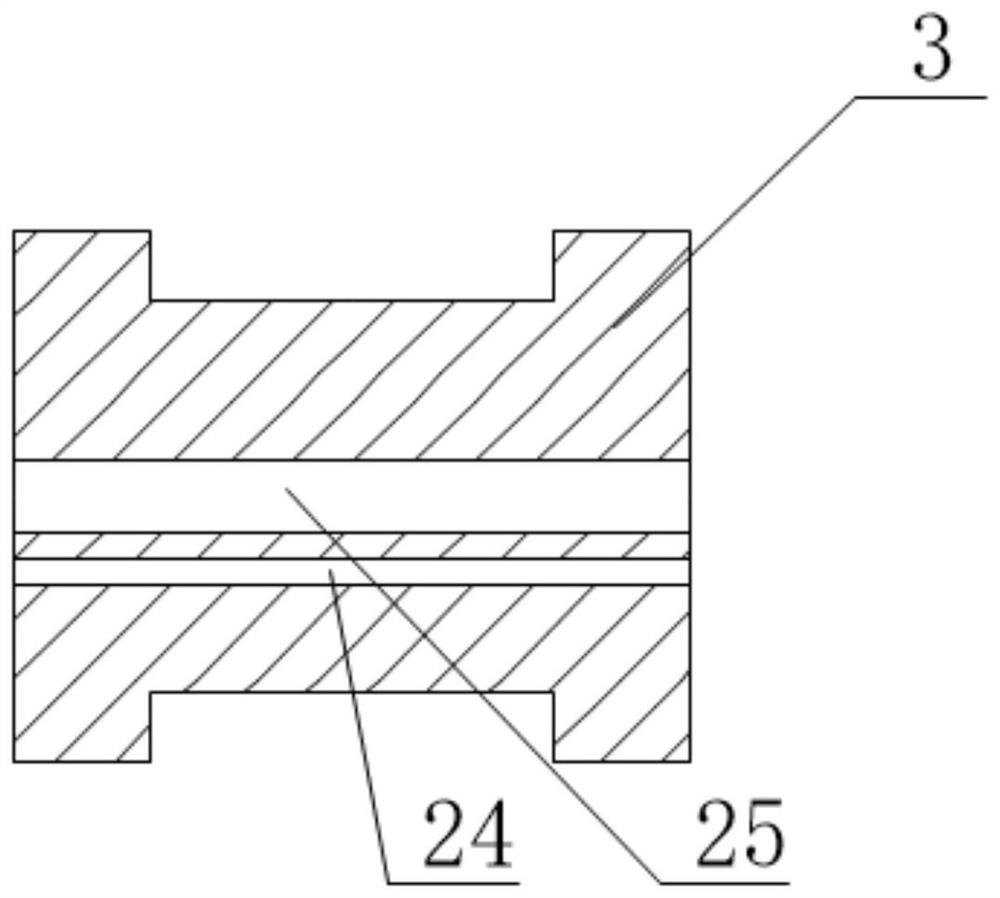

[0049] Specific implementation mode two: the following combination figure 1 with2 This embodiment will be described. The first embodiment will be further described in this embodiment, and the rubber ring 13 is also included. The rubber ring 13 is arranged between the inner arms of the two slider fixing rings 4 and the cantilever beam 12 .

specific Embodiment approach 3

[0050] Specific implementation mode three: the following combination Image 6 Illustrate this embodiment, this embodiment is described further to embodiment one or two, also comprises control unit, and described control unit is used for controlling the operation of stepper motor 18, and control unit comprises motor drive module 19 and single-chip microcomputer 20, and single-chip microcomputer 20 The stepper motor 18 is controlled by the motor drive module 19 to rotate forward or reversely, and the steel wire 11 is pulled to drive the vibration-damping structure to move forward and backward.

[0051] The control process for variable stiffness of the damping structure: install the slider fixing ring 4 at both ends of the slider 3 respectively, and fix it with the bolt 5. The rubber ring 13 is installed in the inner hole of the slider fixing ring 4, and slides with the cantilever beam 12. The slider The coil 2 is wound in the middle. The cantilever beam 12 is fixed on the cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com