Small-diameter log defibering production line

A production line and log technology, which is applied in the direction of wood processing equipment, forming/shaping machines, special forming/shaping machines, etc., can solve the problems of undisclosed shrub decompression processing, etc., so as to improve the decompression processing efficiency, improve the utilization rate of logs, and improve The effect of flexibility

Active Publication Date: 2021-12-21

安吉天友机械科技有限公司

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The above-mentioned patent does not disclose how to decompose the shrubs. In order to make full use of the existing small-diameter logs (about 30-110mm in diameter), this small-diameter log decompression production line was developed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0100] Structure and Principle of the present embodiment is substantially the same as the first embodiment except that the structure of: breaking any one cross cut knife 2 and the knife m word.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

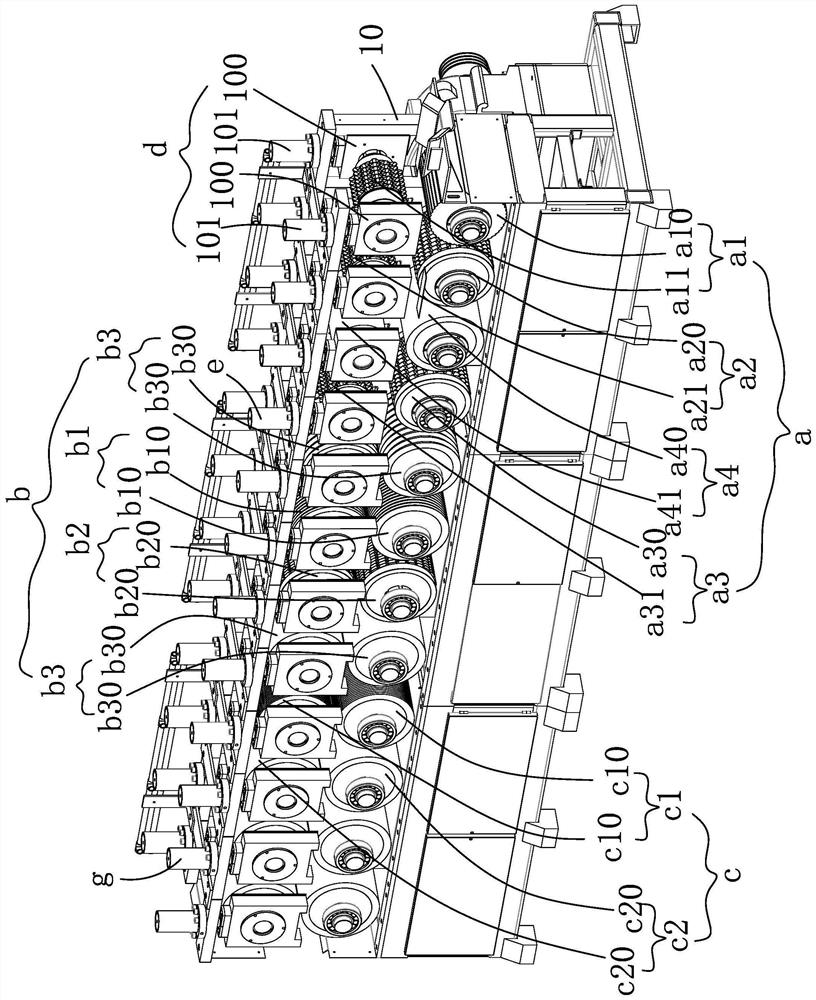

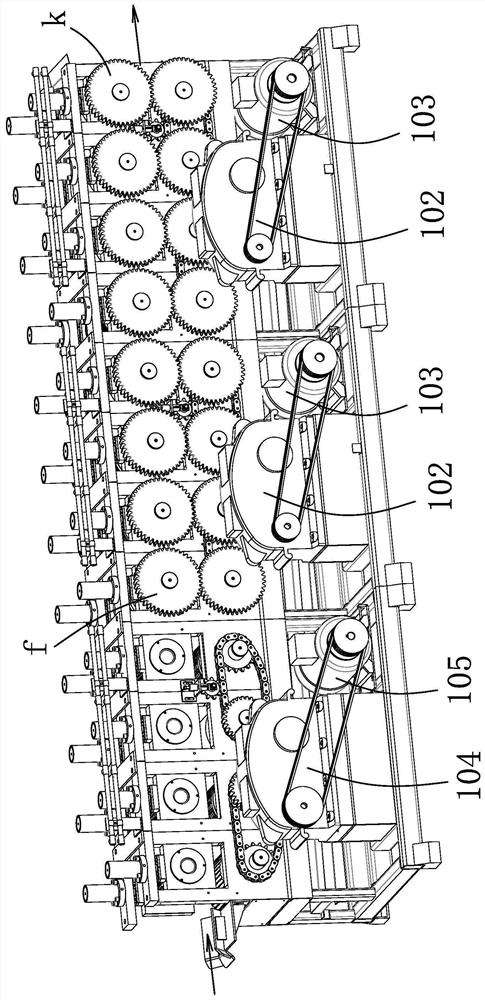

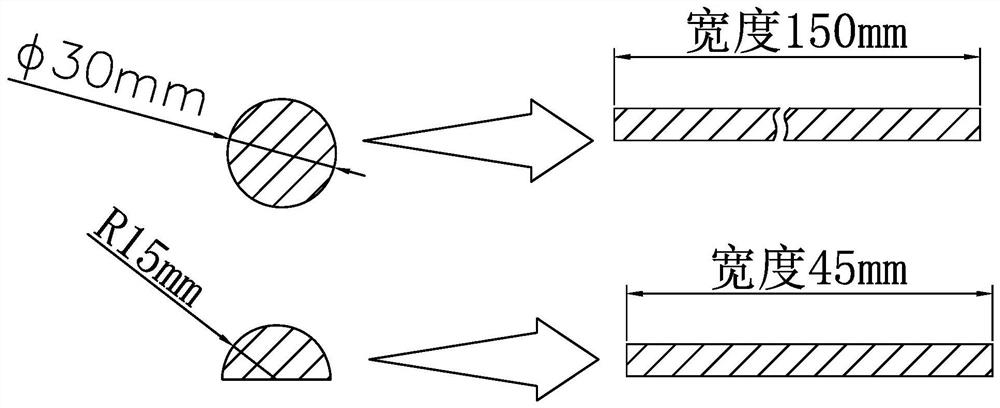

The invention belongs to the technical field of mechanical equipment, and particularly relates to small-diameter log defibering equipment. The technical problems that an existing design is unreasonable and the like are solved. The small-diameter log defibering equipment comprises a first-stage processing unit used for conducting first-stage defibering processing on a small-diameter log to obtain first-stage flaky defibering materials with the width of larger than the diameter of the small-diameter log and the thickness of smaller than the diameter or radius of the small-diameter log, a second-stage processing unit used for performing second-stage defibering processing on the first-stage flaky defibering materials to obtain second-stage flaky defibering materials with the width of larger than that of the first-stage flaky defibering materials and the thickness of smaller than that of the first-stage flaky defibering materials, and a third-stage processing unit used for performing third-stage defibering processing on the second-stage flaky defibering materials to obtain third-stage flaky defibering materials with the width of larger than that of the second-stage flaky defibering materials and the thickness of smaller than that of the second-stage flaky defibering materials. The equipment has the advantages that mechanical defibering is achieved, and the log is utilized more sufficiently.

Description

Technical field [0001] The present invention belongs to the technical field of machinery and equipment, particularly to a small-diameter timber ease production line. Background technique [0002] In order to improve the utilization of wood materials, for example, Chinese patent discloses a CN106003275B- an automatic production equipment and method for producing wood-based material as shrubs profile, although this method which is utilized to optimize the use of bushes, which process wherein discloses a [0034] section, are rolled on the pavement by the ease, dipping, bar bush after drying treatment by the pavement and cutting means. [0003] The aforementioned patent does not disclose how its specific shrubs ease processing, in order to make full use of existing logs of small diameter (diameter between about 30-110mm), so ease the development of this small-diameter timber production line. Inventive content [0004] Object of the present invention is directed to the above-described...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B27C5/02B27C5/06

CPCB27C5/02B27C5/06Y02W30/78

Inventor 黄学良黄鹏

Owner 安吉天友机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com