A kind of preparation method of nanometer hafnium boride powder

A technology of nano-boron and hafnium boride, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of difficult balance between purity and particle size, high production cost, etc., achieve good shape characteristics, short production cycle, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

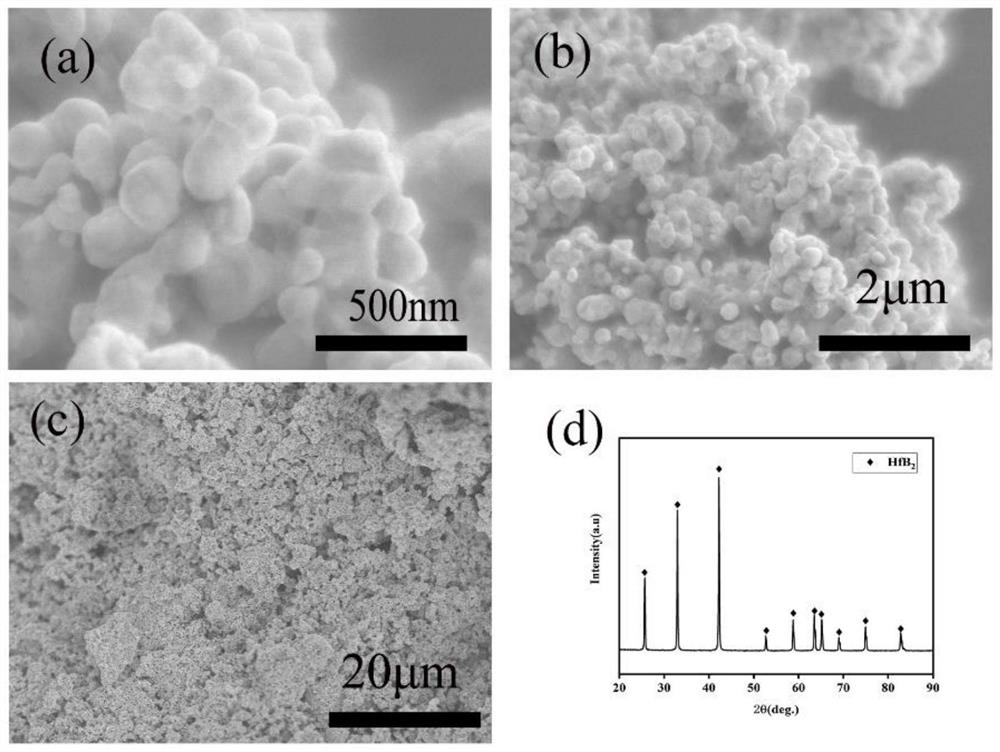

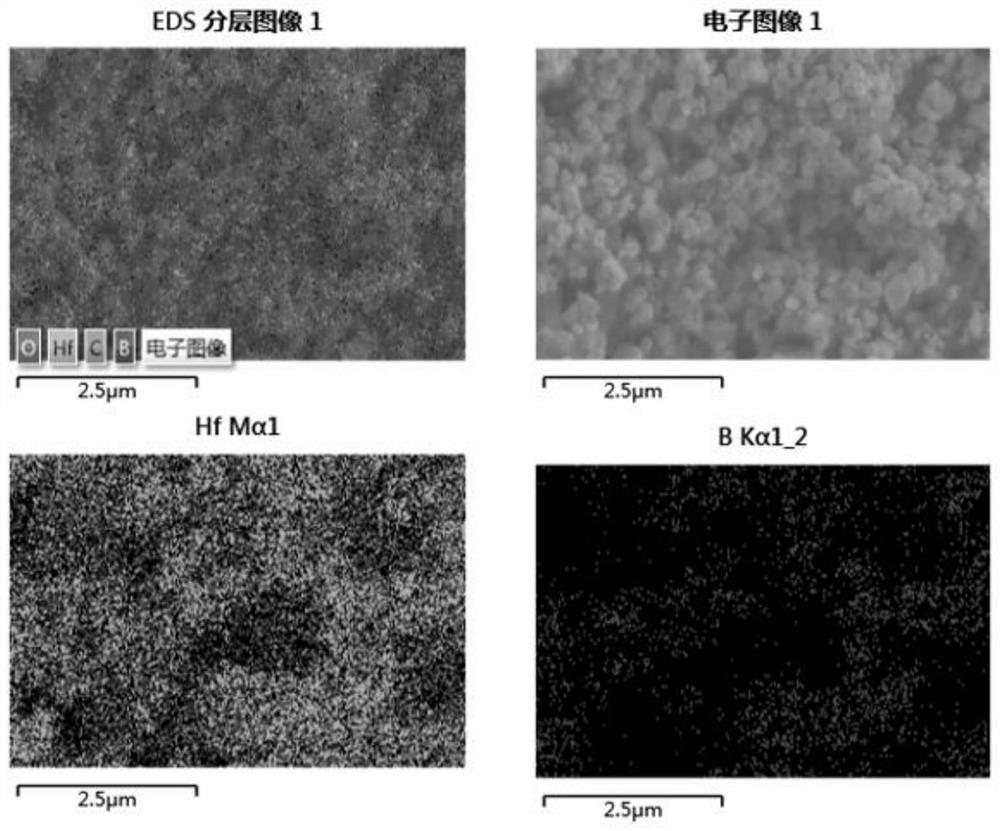

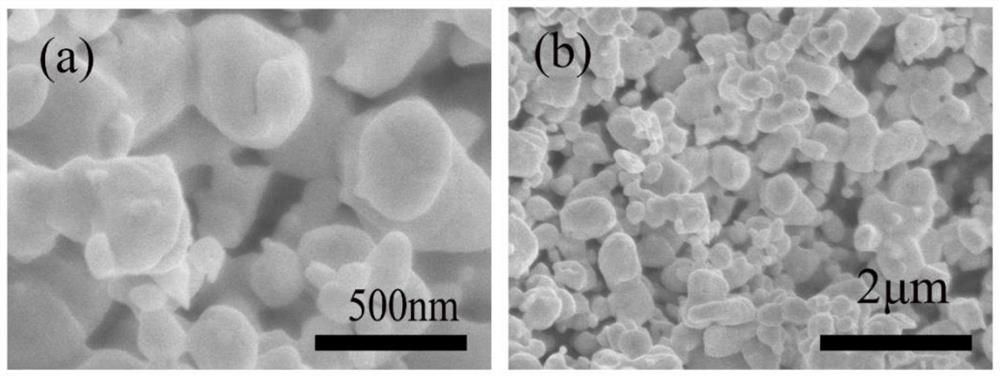

Image

Examples

Embodiment 1

[0032] A method for preparing hafnium boride powder by co-precipitation method, comprising the following steps:

[0033] Step S1, weigh 2.0g of boric acid and 3.5g of sorbitol, put them into the same beaker and mix, then pour 10mL of acetic acid (analytical grade) into it, and use a magnetic stirrer to gradually heat up to 80°C under oil bath heating conditions, Stirring at constant temperature until boric acid and sorbitol are completely dissolved in acetic acid, and the solution is completely clarified, thereby obtaining a clear mixed solution A and cooling to room temperature;

[0034] Step S2, measure 6mL of acetic acid (analytical grade) and pour it into a beaker, weigh 3.2g of hafnium chloride and slowly pour it into it and keep stirring to obtain a pale yellow transparent mixed solution B;

[0035] Step S3, under the state of continuous stirring, the mixed solution B is slowly dropped into the mixed solution B at a uniform speed of 1 mL / min, thereby obtaining a white ha...

Embodiment 2

[0039] A method for preparing 100-gram grade hafnium boride powder by co-precipitation method, comprising the following steps:

[0040] Step S1, weigh 20g of boric acid and 35g of sorbitol, put it into the same beaker and mix, then pour 100mL of acetic acid (analytical grade) into it, and use an oil bath magnetic stirrer to gradually heat it up to 80 ° C, and stir at constant temperature until Boric acid and sorbitol are completely dissolved in acetic acid, and the solution is completely clarified, thereby obtaining a clear mixed solution A and cooling to room temperature;

[0041] Step S2, measure 80mL of acetic acid (analytical grade) and pour it into a beaker, weigh 32g of hafnium chloride and slowly pour it into it and keep stirring to obtain a pale yellow transparent mixed solution B;

[0042] Step S3, under the state of continuous stirring, the mixed solution B is slowly dripped into the mixed solution B at a uniform speed of 5mL / min, thereby obtaining a white hafnium bo...

Embodiment 3

[0046] A method for preparing hafnium boride powder by co-precipitation method, comprising the following steps:

[0047] Step S1, weigh 2.0g of boric acid and 3.8g of sorbitol, put it into the same beaker and mix, then pour 10mL of acetic acid (analytical grade) into it, and use a magnetic stirrer to gradually heat up to 60°C under oil bath heating conditions, Stirring at constant temperature until boric acid and sorbitol are completely dissolved in acetic acid, and the solution is completely clarified, thereby obtaining a clear mixed solution A and cooling to room temperature;

[0048] Step S2, measure 8mL of acetic acid (analytical grade) and pour it into a beaker, weigh 3.0g of hafnium chloride and slowly pour it into it and keep stirring to obtain a pale yellow transparent mixed solution B;

[0049] Step S3, under the state of continuous stirring, the mixed solution B is slowly dropped into the mixed solution B at a uniform speed of 1 mL / min, thereby obtaining a white hafn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com