A kind of preparation method of hollow cerium oxide

A cerium oxide, hollow technology, which is applied in the field of preparation of hollow cerium oxide, can solve the problems of poor dispersibility and easy agglomeration of hollow cerium oxide, and achieve the effect of good dispersibility, good shape characteristics and reduced influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

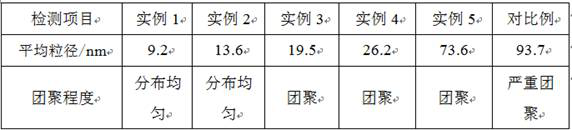

Examples

example 1

[0023] Mix glucose and water in a beaker at a mass ratio of 1:25, and add potassium iodate 0.2 times the mass of glucose to the beaker, and stir and mix for 180 minutes at a temperature of 65°C and a rotational speed of 350r / min to obtain Glucose mixed solution, mix glucose mixed solution with barium chloride solution with a mass fraction of 20% at a mass ratio of 1:5, stir and mix for 40 minutes at a temperature of 45°C and a rotational speed of 400r / min, and then filter to obtain Filtrate, mix the filtrate and sodium sulfate solution with a mass fraction of 22% at a mass ratio of 1:4, stir and mix for 40 minutes at a temperature of 45°C and a rotational speed of 400r / min, then filter to remove the filter cake. Dextrose mixed liquid; pulverize microcrystalline cellulose and pass through a 120-mesh sieve to obtain refined microcrystalline cellulose, and mix the refined microcrystalline cellulose and sodium hydroxide solution with a mass fraction of 25% in a mass ratio of 1:12 ...

example 2

[0025]Mix glucose and water in a beaker at a mass ratio of 1:25, and add potassium iodate 0.2 times the mass of glucose to the beaker, and stir and mix for 180 minutes at a temperature of 65°C and a rotational speed of 350r / min to obtain Glucose mixed solution, mix glucose mixed solution with barium chloride solution with a mass fraction of 20% at a mass ratio of 1:5, stir and mix for 40 minutes at a temperature of 45°C and a rotational speed of 400r / min, and then filter to obtain Filtrate, mix the filtrate and sodium sulfate solution with a mass fraction of 22% at a mass ratio of 1:4, stir and mix for 40 minutes at a temperature of 45°C and a rotational speed of 400r / min, then filter to remove the filter cake. mixed solution of glucose; chitosan and glacial acetic acid solution with a mass fraction of 4% were mixed in a mass ratio of 1:60, and urea 5 times the mass of chitosan was added to the mixture of chitosan and glacial acetic acid solution, The temperature is 40°C, the ...

example 3

[0027] Mix glucose and water in a beaker at a mass ratio of 1:25, and add potassium iodate 0.2 times the mass of glucose to the beaker, and stir and mix for 180 minutes at a temperature of 65°C and a rotational speed of 350r / min to obtain Glucose mixed solution, mix glucose mixed solution with barium chloride solution with a mass fraction of 20% at a mass ratio of 1:5, stir and mix for 40 minutes at a temperature of 45°C and a rotational speed of 400r / min, and then filter to obtain Filtrate, mix the filtrate and sodium sulfate solution with a mass fraction of 22% at a mass ratio of 1:4, stir and mix for 40 minutes at a temperature of 45°C and a rotational speed of 400r / min, then filter to remove the filter cake. Dextrose mixed liquid; pulverize microcrystalline cellulose and pass through a 120-mesh sieve to obtain refined microcrystalline cellulose, and mix the refined microcrystalline cellulose and sodium hydroxide solution with a mass fraction of 25% in a mass ratio of 1:12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com