A kind of nitrogen-doped graphdiyne riveted transition metal single-atom catalyst and its preparation method and application

A transition metal and transition metal salt technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of reduced catalyst activity, limited non-precious metal catalyst activity, low atom utilization, etc., and achieve high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

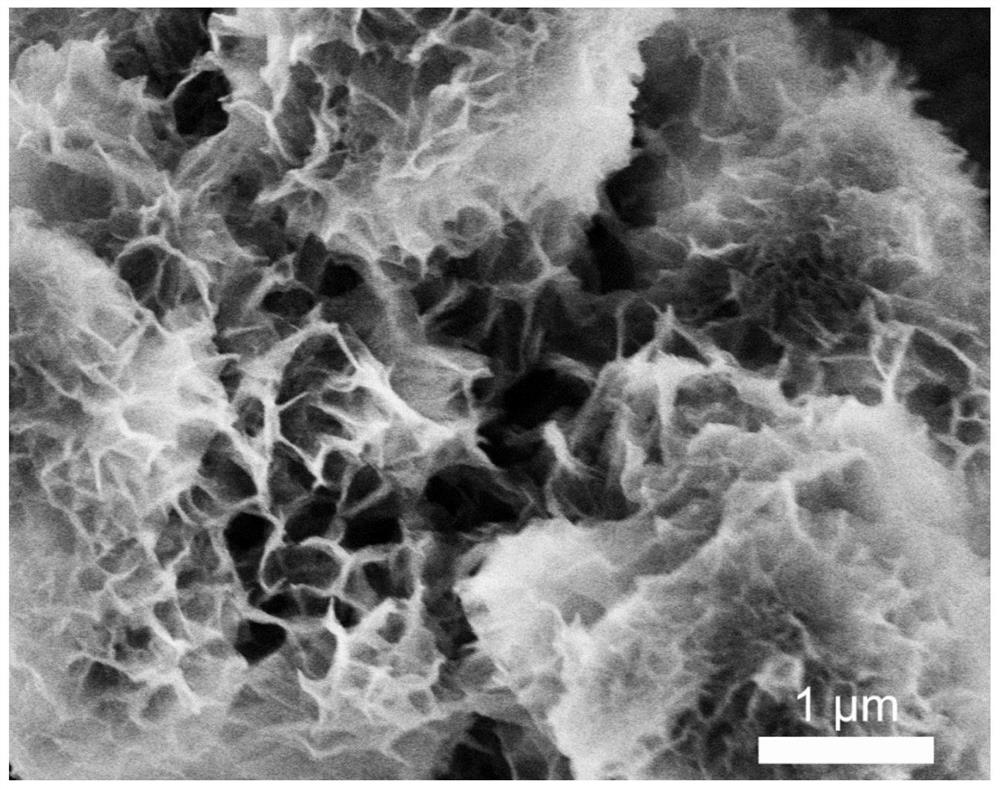

[0040]Dissolve 50 mg of hexa[trimethylsilyl]ethynyl]benzene in 15 mL of tetrahydrofuran, stir for 1 h under Ar gas purging, add 1 mL of tetrabutylammonium fluoride at 0°C for 15 min; add 20 mL of ethyl acetate to dilute, Then add 20 mL of saturated saline to wash three times, extract and separate the liquid to take the upper layer solution, add 20 mg of anhydrous magnesium sulfate to remove water and filter, and the mixture is rotary evaporated at 45 ° C to remove the solvent to obtain a yellow solid hexaethynylbenzene; 100 mL of acetone and 5 mL Pyridine, 1mL tetramethylethylenediamine, and 2*2cm*10 acid-washed copper foil were stirred at 50°C for 2h under the protection of Ar gas to obtain a mixture, and the hexaethynylbenzene obtained in the previous step was dissolved in 50mL of acetone, and the Slowly add the above mixture to react for 36h; centrifuge the reacted mixture at 10000r / min to get the black solid, and wash it with N,N,N,N-tetramethylethylenediamine, acetone, eth...

Embodiment 2

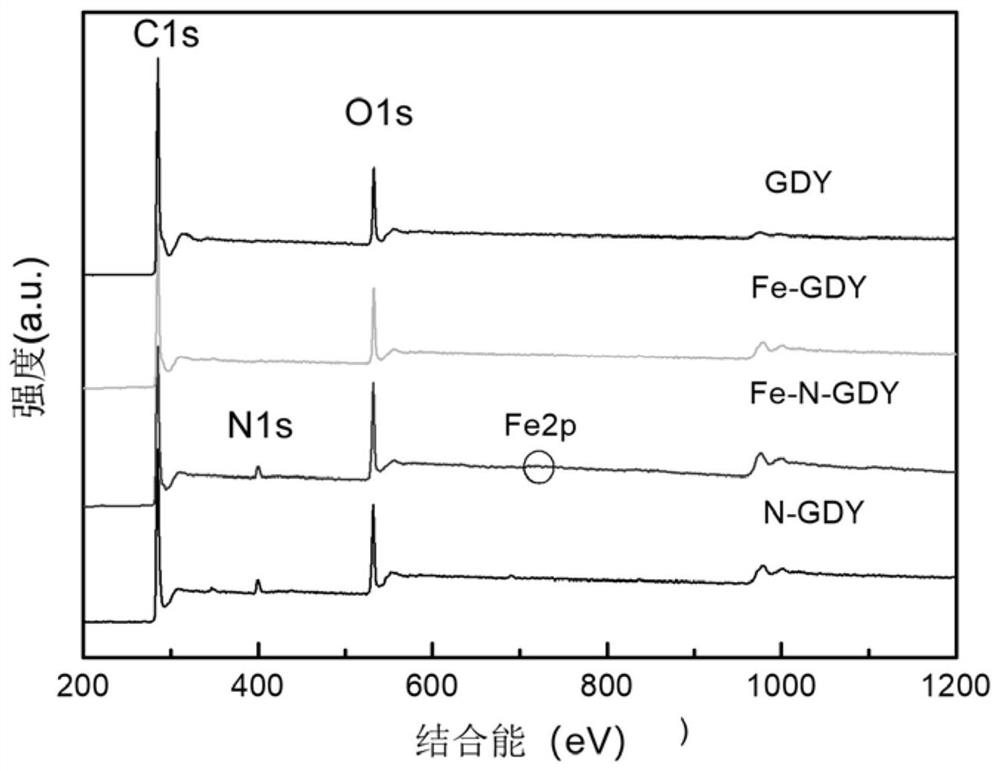

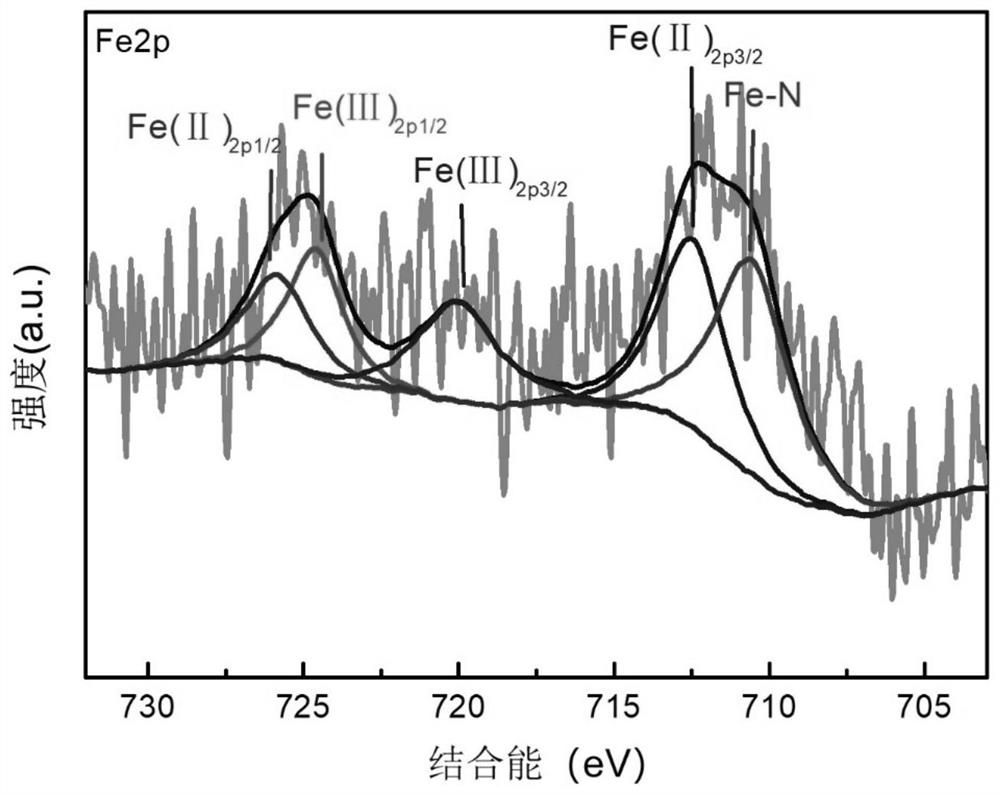

[0042] Mix 10 mg of graphyne synthesized in Example 1 with 50 mg of melamine in 30 mL of ethanol (AR), and stir thoroughly at room temperature 20° C. for 12 h; place the mixture in a vacuum oven at 70° C. and dry for 6 h to obtain mixture A; The dried mixture A was placed in a tube furnace, heated to 900°C for 2 hours under an Ar gas atmosphere, and pyrolyzed at a rate of 5°C / min, and cooled to room temperature to obtain a black solid B; all the black solid B was mixed with 0.1 Disperse mol of ferric chloride hexahydrate into 30mL water, stir magnetically under Ar atmosphere at 25°C for 12h to obtain mixture C, use a 200W power ultrasonic machine to sonicate for 10min, and centrifuge at 10000r / min for 10min to obtain solid precipitate D; all solid precipitate D Disperse in 30mL of water, dissolve 5mg of sodium borohydride in 10mL of water, add to the above dispersion under Ar atmosphere, stir with a magnetic stirrer at 20°C for 12h; wash the stirred mixed solution twice with wa...

Embodiment 3

[0045] The preparation method of embodiment 3 is the same as that of embodiment 2, except that ferric chloride hexahydrate is replaced by ferric nitrate nonahydrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com