Pressure-bearing type uplift pile and precast pile connecting structure and construction method thereof

A technology for connecting structures and construction methods, applied in basic structure engineering, sheet pile walls, buildings, etc., can solve problems such as endangering building safety, building floating, and long time, reducing project cost, reducing construction strength, and anti-uplift bearing. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0057] The construction method of the pressure-bearing type uplift pile prefabricated pile connection structure described in embodiment 2 comprises the following steps:

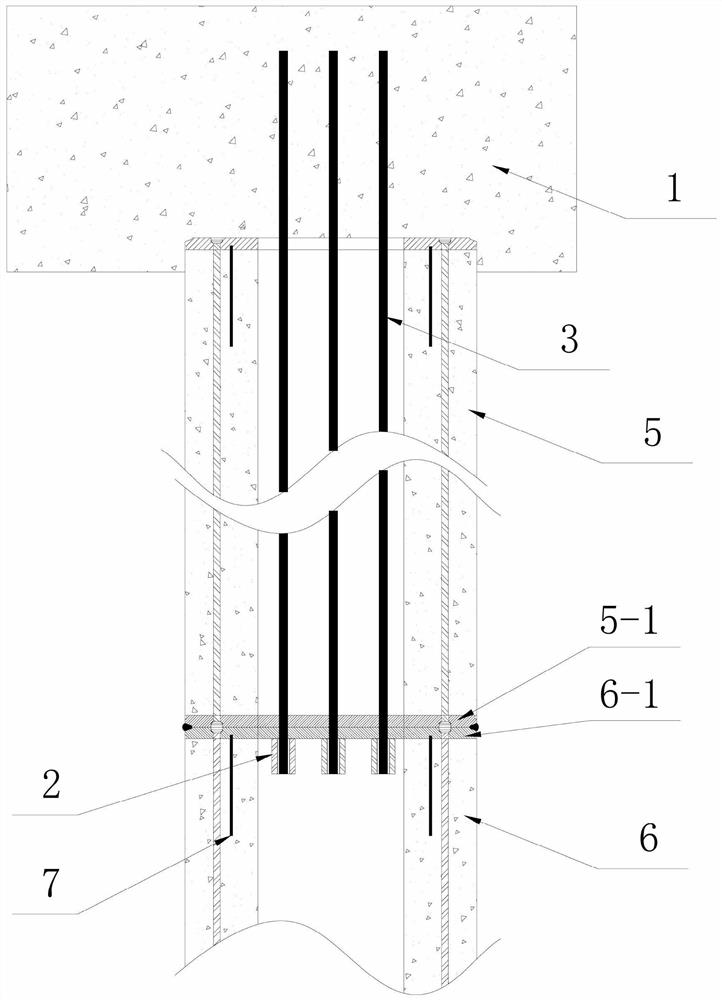

[0058] When producing the second concrete pile body 6, a threaded sleeve 2 is installed on the anchor plate at one end of the second concrete pile body 6, and the threaded sleeve 2 is located in the pile body of the second section concrete pile body 6; During the production process of the first section concrete pile body 5, several through holes are provided in the pile body of the first section concrete pile body 5, and one end of the connecting rib 3 passes through the through hole and the threaded sleeve of the first section concrete pile body 5. Cartridge 2 is connected. When producing the concrete pile body, one end of the anchor reinforcement 7 is installed on the anchor plate, and the other end is pre-embedded in the pile body.

[0059] Through construction, one end of the concrete pile body 6 of the ...

Embodiment 3

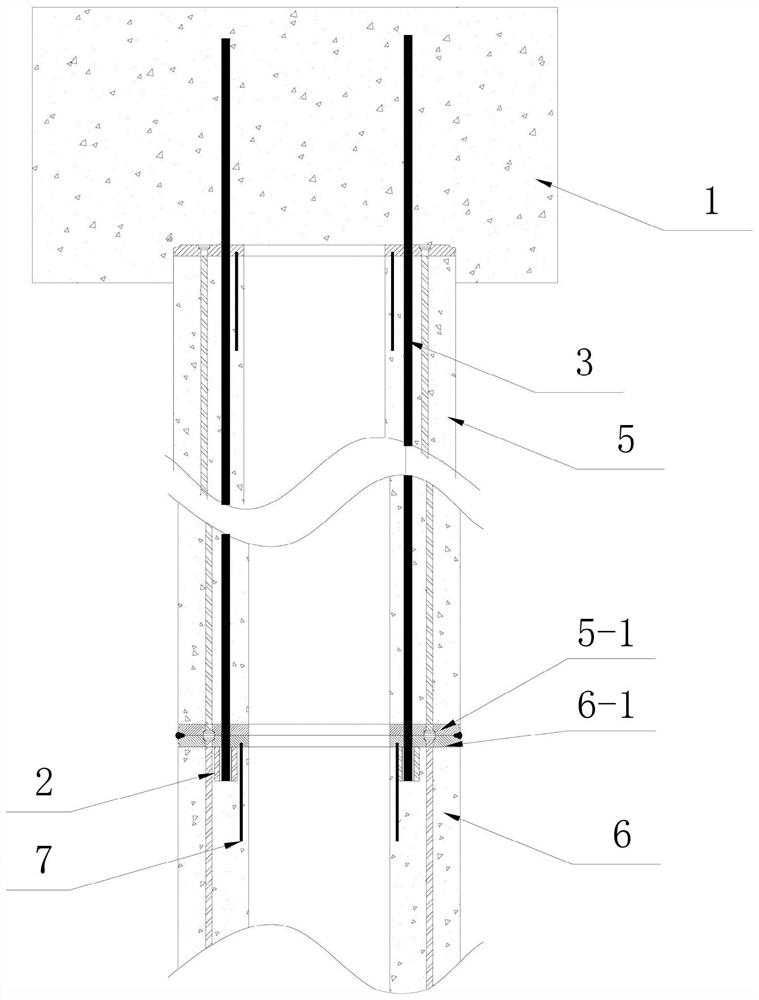

[0064] The construction method of the pressure-bearing type uplift pile prefabricated pile connection structure described in embodiment 3 comprises the following steps:

[0065] A threaded sleeve 2 is installed on the other side of the reaction force plate 7, and one end of the connecting rib 3 is connected with the threaded sleeve 2; when producing a concrete pile, one end of the anchoring rib 7 is installed on the anchor plate, and the other end is pre-embedded inside the pile.

[0066] Through construction, one end of the first concrete pile body 5 is exposed to the mounting surface of the cap 1;

[0067] Place the assembly of the reaction force plate 7 and the connecting rib 3 in the cavity of the set concrete pile body, and place the secondary grouting area between the side of the reaction force plate 7 and the anchor plate of the set concrete pile body Concrete is poured inside, and the reaction plate 7 is fixed through the solidification of the concrete; the scale can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com