Anti-skid control method, system and device for spading of loader

A control method and control device technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of affecting work efficiency, low level of vehicle intelligence, and reduced operating comfort and other issues, to achieve the effect of improving the level of intelligence, upgrading of intelligent technology, and improving operating comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

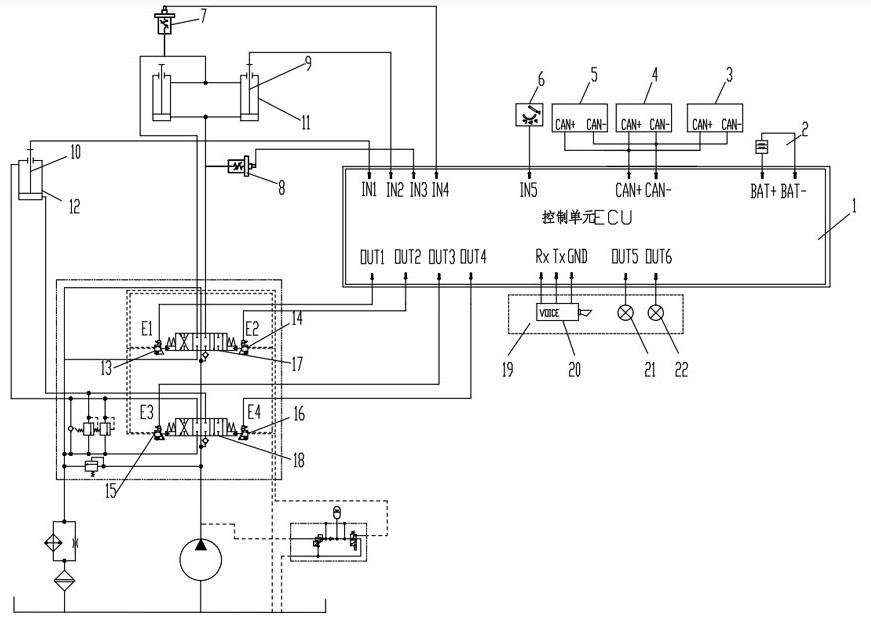

[0032] Such as figure 1 As shown, a loader shovel anti-slip control method provided in an embodiment of the present invention includes the following steps:

[0033] In response to detecting that the loader is in a slipping state, an instruction is sent to the boom cylinder 11 to control the boom cylinder 11 to perform a lifting action until it is detected that the loader is in a non-skidding state or the stroke of the boom cylinder 11 meets the preset first stroke requirement;

[0034] In response to detecting that the loader is in a non-slip state, an instruction is issued to the bucket cylinder 12 to control the bucket cylinder 12 to perform the action of retracting the bucket until it is detected that the loader is in a slipping state or the stroke of the bucket cylinder 12 meets the preset second stroke requirement .

[0035] The preset first stroke requirement is that the stroke of the boom cylinder 11 reaches the set threshold value, and the preset second stroke require...

Embodiment 2

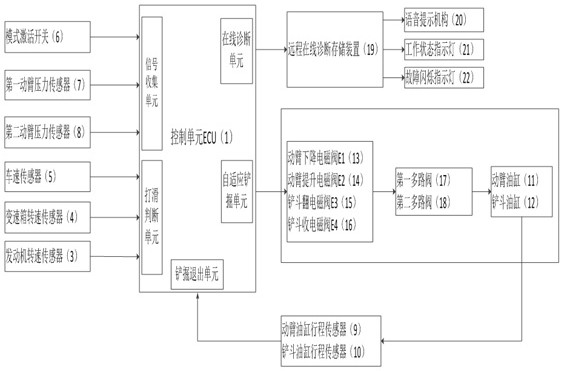

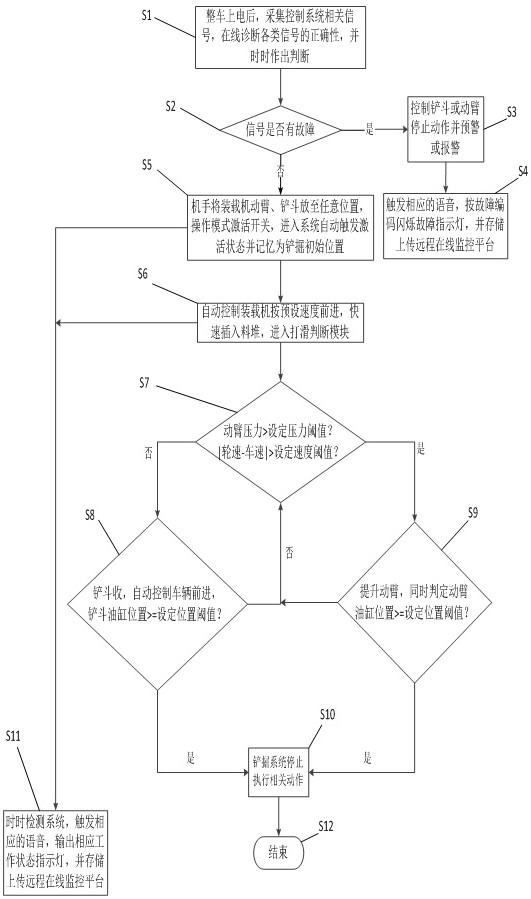

[0040] Such as figure 2 and image 3 As shown, a loader shovel anti-slip control method provided in an embodiment of the present invention includes the following steps:

[0041] S1. After the vehicle is powered on, collect relevant signals of the control system, judge the correctness of various signals online, and make judgments from time to time;

[0042]S2. Determine whether the collected signal is faulty, if so, execute S3; if not, execute S5;

[0043] S3. According to the failure situation, control the bucket or the boom to stop and give an early warning or alarm;

[0044] S4. According to the execution situation of S3, trigger corresponding voice, flash the fault flashing indicator light 22 according to the fault code, store and upload data to the remote online monitoring platform;

[0045] S5. The operator puts the arm and bucket of the loader to the position to be shoveled, activates the switch 6 in the operation mode, enters the automatic trigger activation state o...

Embodiment 3

[0056] Such as figure 1 As shown, a loader shovel anti-skid control system provided by an embodiment of the present invention includes:

[0057] Boom lifting module: in response to detecting that the loader is in a slipping state, issue a boom cylinder 11 command to control the boom cylinder 11 to perform a lifting action until it is detected that the loader is in a non-skidding state or the stroke of the boom cylinder 11 meets the preset first trip requirements;

[0058] Bucket retracting module: in response to detecting that the loader is in a non-slip state, issue a bucket cylinder 12 command to control the bucket cylinder 12 to perform bucket retraction until it is detected that the loader is in a slipping state or the stroke of the bucket cylinder 12 meets the predetermined Set second trip requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com