Wind turbine generator blade unmanned aerial vehicle inspection defect detection method and device and storage medium

A technology for defect detection and wind turbines, applied in neural learning methods, image data processing, image enhancement, etc., can solve a large number of artificially designed features and other problems, and achieve high recognition accuracy and real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

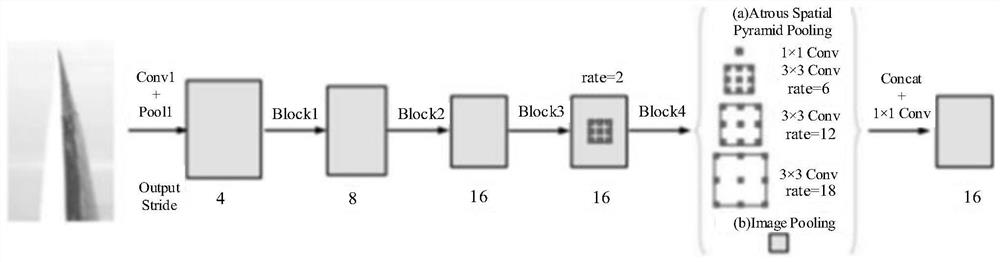

Method used

Image

Examples

Embodiment 1

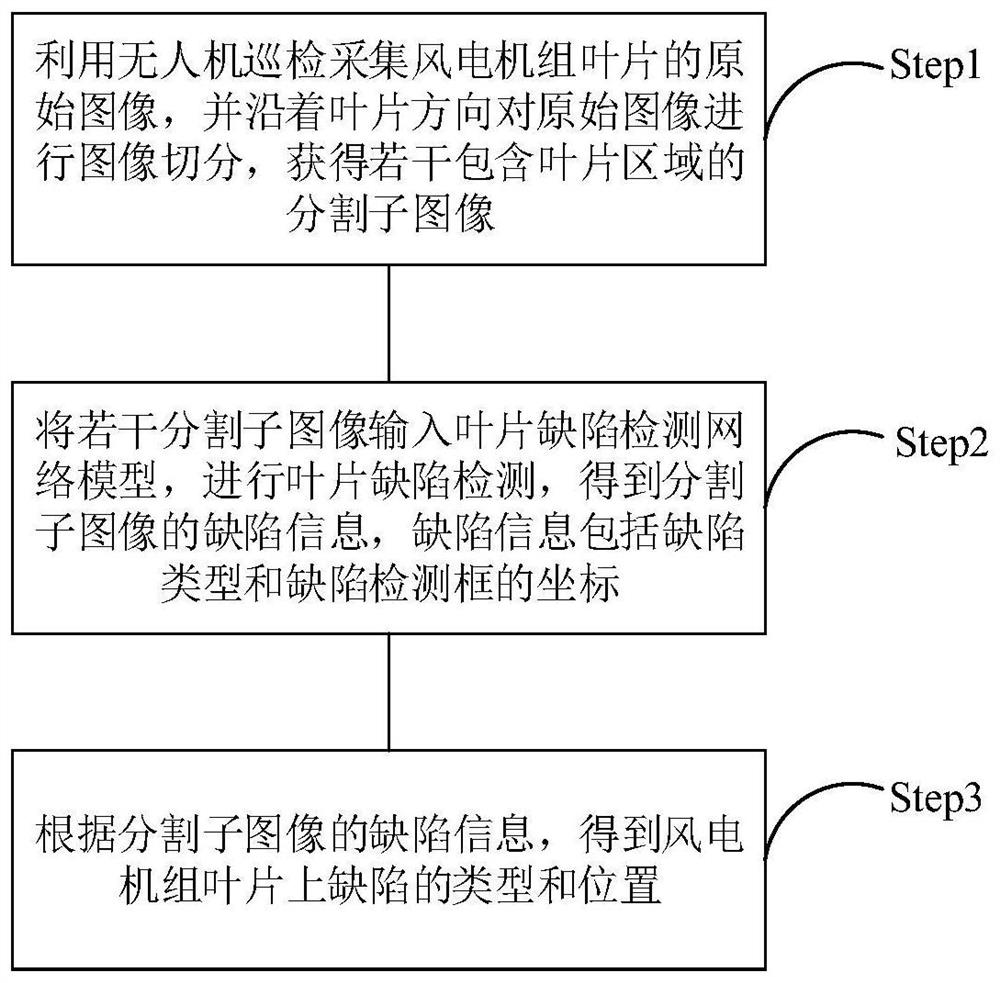

[0054] See figure 1 , figure 1 It is a flowchart of a defect detection method for wind turbine blade UAV patrol inspection provided by an embodiment of the present invention. As shown, the method includes:

[0055] Step1: Use the UAV to inspect and collect the original image of the blade of the wind turbine, and segment the original image along the direction of the blade to obtain several sub-images including the blade area;

[0056] Step2: Input several segmented sub-images into the leaf defect detection network model for leaf defect detection, and obtain the defect information of the segmented sub-images. The defect information includes the defect type and the coordinates of the defect detection frame;

[0057] Step3: According to the defect information of the segmented sub-image, the type and position of the defect on the blade of the wind turbine are obtained.

[0058] Specifically, in this embodiment, the UAV is equipped with a camera, and the UAV is controlled to take...

Embodiment 2

[0131] On the basis of the above embodiments, this embodiment provides a wind turbine blade UAV inspection defect detection device for implementing the wind turbine blade UAV inspection defect detection method in Embodiment 1.

[0132] See Figure 11 , Figure 11 It is a structural block diagram of a wind turbine blade UAV inspection defect detection device provided by an embodiment of the present invention. As shown in the figure, the device of this embodiment includes: an image acquisition module 10, an image segmentation module 20, a blade defect detection module 30 and a data processing module 40.

[0133] Wherein, the image acquisition module 10 is used to acquire the original image of the wind turbine blade. The image segmentation module 20 is used to perform image segmentation on the original image along the direction of the blade to obtain several sub-images that include the blade area. It should be noted that the spliced image of the several sub-images includes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com