Thin film transistor and manufacturing method thereof, display substrate and display device

A technology of thin film transistors and manufacturing methods, applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of unfavorable display device display quality, poor characteristics of thin film transistors, etc., to improve mobility characteristics, improve work efficiency, Improve display quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to further illustrate the thin film transistor, the manufacturing method thereof, the display substrate, and the display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

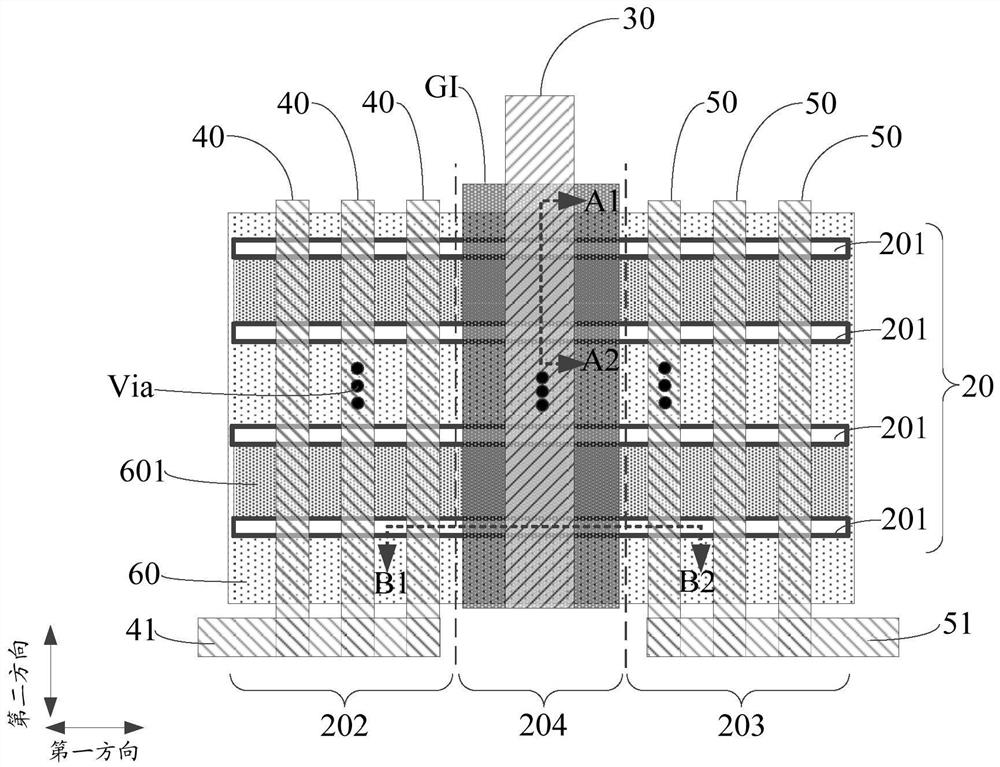

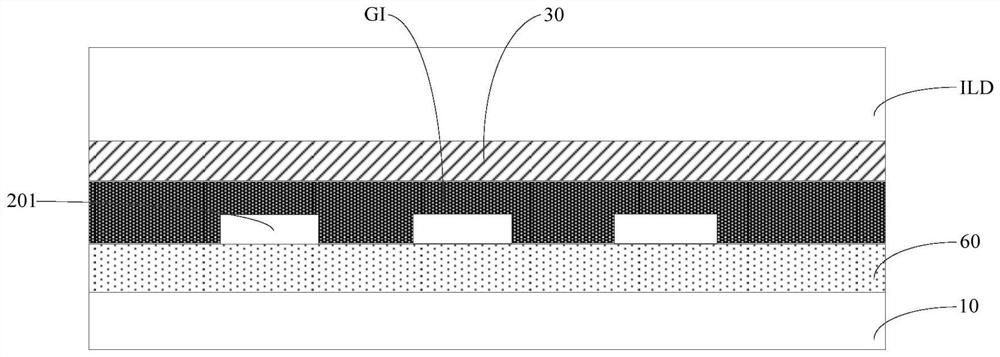

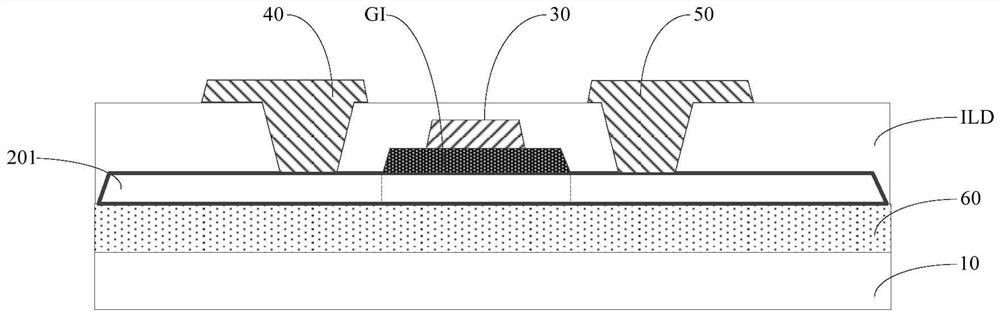

[0070] see Figure 1 ~ Figure 2b , the embodiment of the present invention provides a thin film transistor, including: a substrate 10, an active layer 20 disposed on the substrate 10, a gate 30, a source and a drain; the active layer 20 is formed as a grid structure, including a plurality of silicon nanowires 201 extending along a first direction, the active layer 20 includes a source region 202 and a drain region 203 oppositely arranged along the first direction, and located in the source region 202 and the channel region 204 between the drain region 203; the gate 30 extends along a second direction, the second direction intersects the first direction, and the gate 30 is on the substrate 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com