LED epitaxial structure and preparation method thereof

An epitaxial structure and structural layer technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing luminous efficiency and affecting the light output efficiency of LED chips, and achieve the effect of improving light output efficiency, reducing internal reflection loss and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

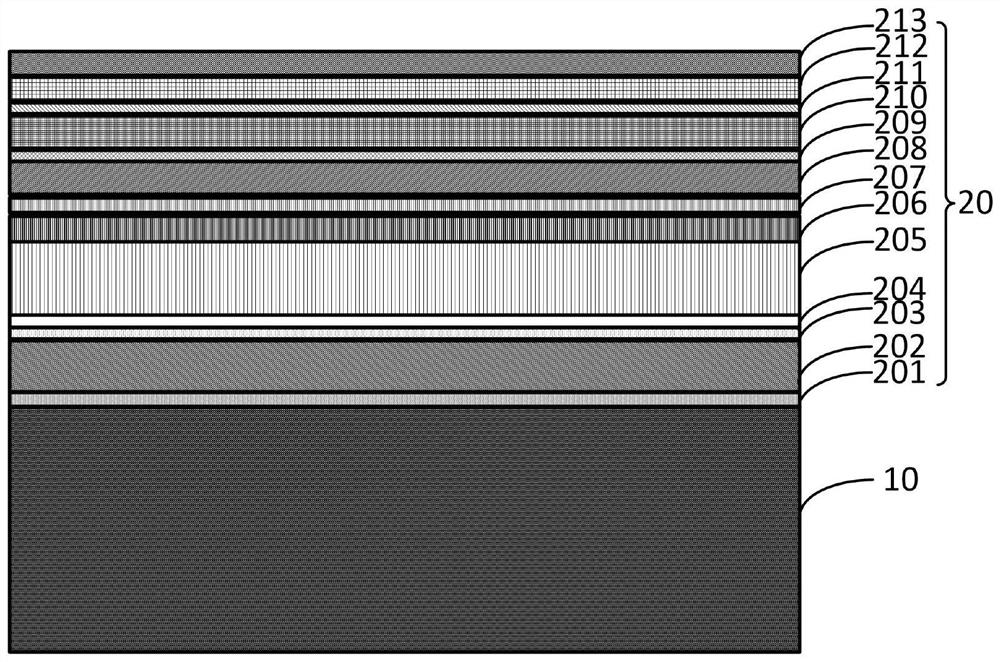

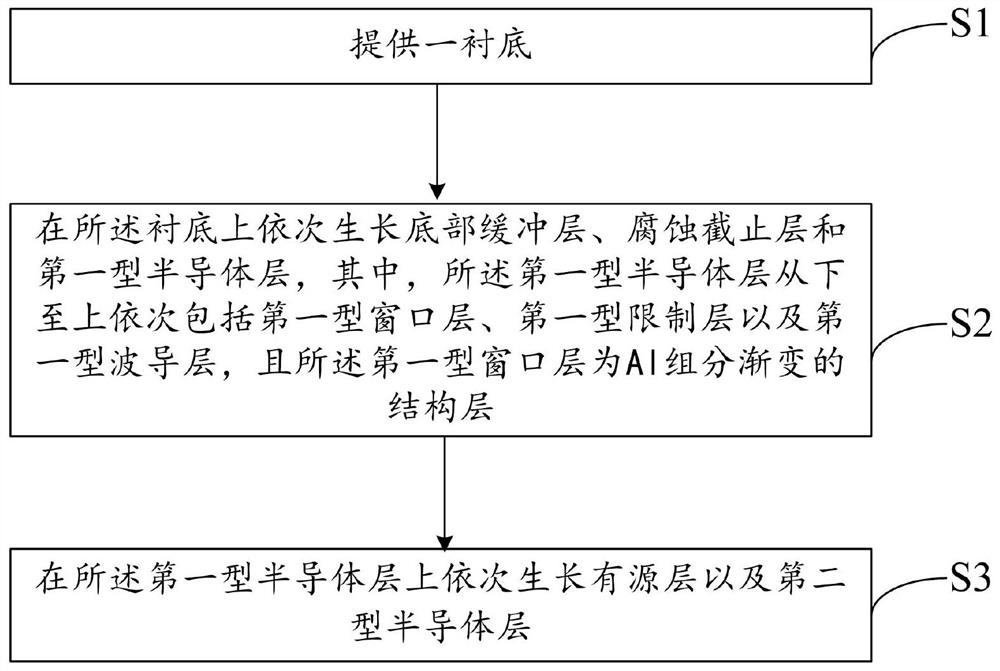

[0043] refer to figure 2 , the preparation method of the LED epitaxial structure 20 specifically includes the following steps:

[0044] Step S1: providing a substrate 10;

[0045] Step S2: growing a bottom buffer layer 201, an etch stop layer 202, and a first-type semiconductor layer sequentially on the substrate 10, wherein the first-type semiconductor layer includes a first-type window layer 205, a first-type semiconductor layer from bottom to top A type-1 confinement layer 206 and a first-type waveguide layer 207, and the first-type window layer 205 is a structural layer with a graded Al composition;

[0046] Step S3: growing an active layer 208 and a second type semiconductor layer sequentially on the first type semiconductor layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com