Moving bed adsorption tower and flue gas purification system with same

An adsorption tower and moving bed technology, applied in gas treatment, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of affecting adsorption efficiency, improving operation difficulty, uneven adsorption, etc., and achieving uniform blanking speed and adsorption effect. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

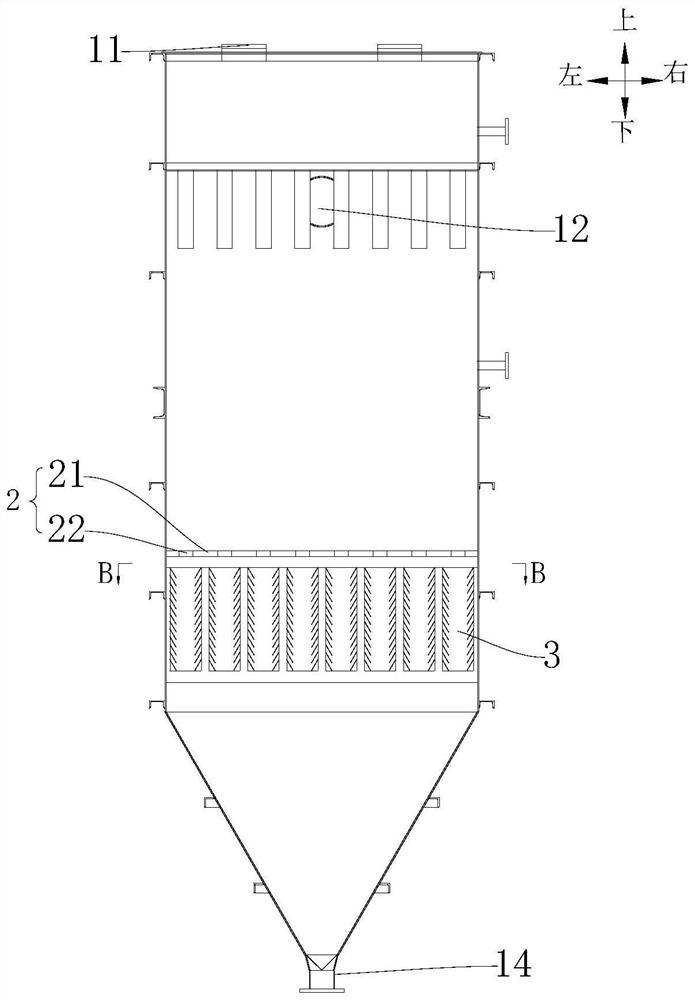

[0032] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

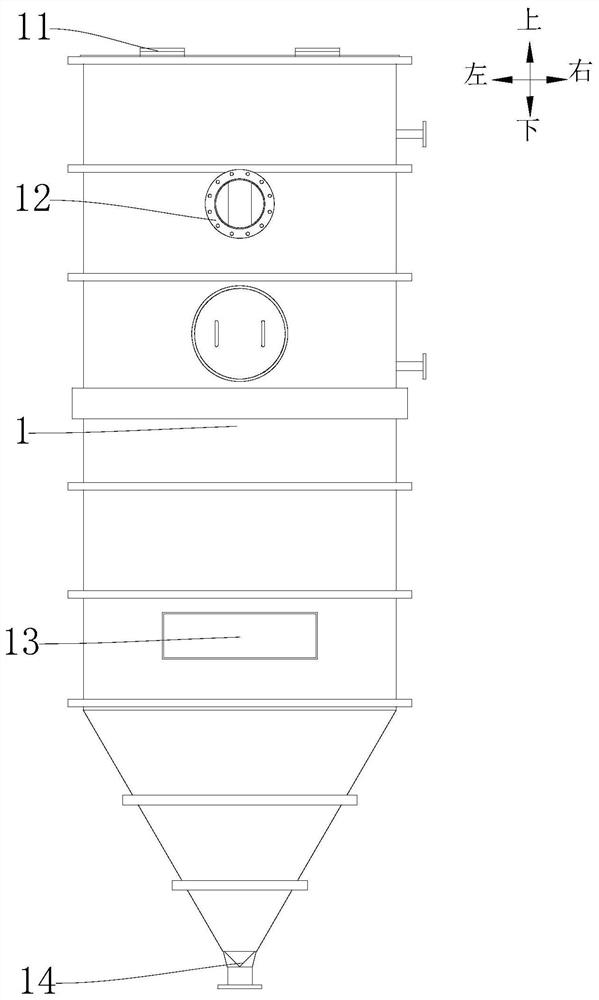

[0033] Such as Figure 1 to Figure 6 As shown, the moving bed adsorption tower according to the embodiment of the present invention includes a tower body 1 , a distributor 2 and a plurality of downcomers 3 .

[0034] There is a cavity in the tower body 1, and the tower body 1 is provided with a feed port 11, a discharge port 14, a flue gas inlet 13 and a flue gas outlet 12 communicating with the cavity, and the cavity includes a packing section filled with an adsorbent;

[0035] Specifically, the feeding port 11 is located at the upper end of the tower body 1, the discharge port 14 is located at the lower end of the tower body 1, the flue gas inlet 13 is located...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com