Honeycomb ceramic carrier for vehicle

A technology for honeycomb ceramic carrier and vehicle, which is applied in the direction of catalyst carrier, organic compound/hydride/coordination complex catalyst, dispersed particle separation, etc. To achieve good catalytic reaction effect, good catalytic effect, and improve the overall utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

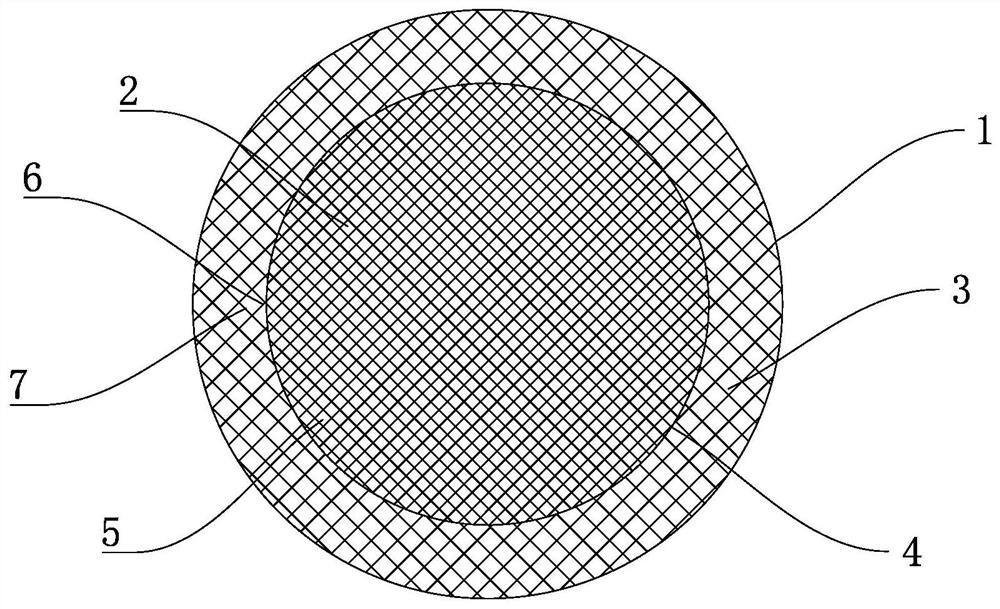

[0028] This embodiment provides a kind of honeycomb ceramic carrier for vehicles, combined with image 3 with Figure 4 As shown, it includes a carrier body 1, and the carrier body 1 is provided with a high-density hole area 2 near the center and a low-density hole area 3 near the edge, and the number of channels 5 per unit area in the high-density hole area 2 is The number is higher than the number of channels 5 per unit area in the low-density hole area 3, and the high-density hole area 2 and the low-density hole area 3 are separated by the transition wall 4. Wherein, the high-density hole region 2 has 900 holes 5 per square inch, the low-density hole region 3 has 400 holes 5 per square inch, and the transition wall 4 has a wall thickness of 0.1 mm.

[0029] In the present invention, when in use, more gas is catalyzed and discharged through the high-density pore region 2 , and less gas is catalyzed and discharged through the low-density pore region 3 . Therefore, the pres...

Embodiment 2

[0036] This embodiment provides a kind of honeycomb ceramic carrier for vehicles, combined with image 3 with Figure 4 As shown, it includes a carrier body 1, and the carrier body 1 is provided with a high-density hole area 2 near the center and a low-density hole area 3 near the edge, and the number of channels 5 per unit area in the high-density hole area 2 is The number is higher than the number of channels 5 per unit area in the low-density hole area 3, and the high-density hole area 2 and the low-density hole area 3 are separated by the transition wall 4. Wherein, the high-density hole area 2 has 1200 holes 5 per square inch, the low-density hole region 3 has 600 holes 5 per square inch, and the transition wall 4 has a wall thickness of 0.15 mm.

[0037] In the present invention, when in use, more gas is catalyzed and discharged through the high-density pore region 2 , and less gas is catalyzed and discharged through the low-density pore region 3 . Therefore, the pres...

Embodiment 3

[0044] This embodiment provides a kind of honeycomb ceramic carrier for vehicles, combined with image 3 with Figure 4 As shown, it includes a carrier body 1, and the carrier body 1 is provided with a high-density hole area 2 near the center and a low-density hole area 3 near the edge, and the number of channels 5 per unit area in the high-density hole area 2 is The number is higher than the number of channels 5 per unit area in the low-density hole area 3, and the high-density hole area 2 and the low-density hole area 3 are separated by the transition wall 4. Wherein, the area of the high-density hole region 2 has 1050 holes 5 per square inch, the area of the low-density hole region 3 has 500 holes 5 per square inch, and the wall thickness of the transition wall 4 is 0.12 mm.

[0045] In the present invention, when in use, more gas is catalyzed and discharged through the high-density pore region 2 , and less gas is catalyzed and discharged through the low-density pore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com