Shearing device based on industrial vision and shearing method thereof

A shearing device and visual technology, applied in the field of automation, can solve the problems of large workpiece allowance, inconvenient secondary processing of workpieces, etc., and achieve the effects of good finished product effect, improved precision value, and prevention of deflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] When using materials to cut workpieces, the conventional process often requires multiple shears, leaving a preset shear allowance each time to facilitate the next processing. This type of process is more troublesome and the process is more complicated. Especially for workpieces with a certain thickness, the thickness surface may be required to be provided with a specified inclined surface. Conventional shearing devices are often linear and are not suitable for this type of shearing process.

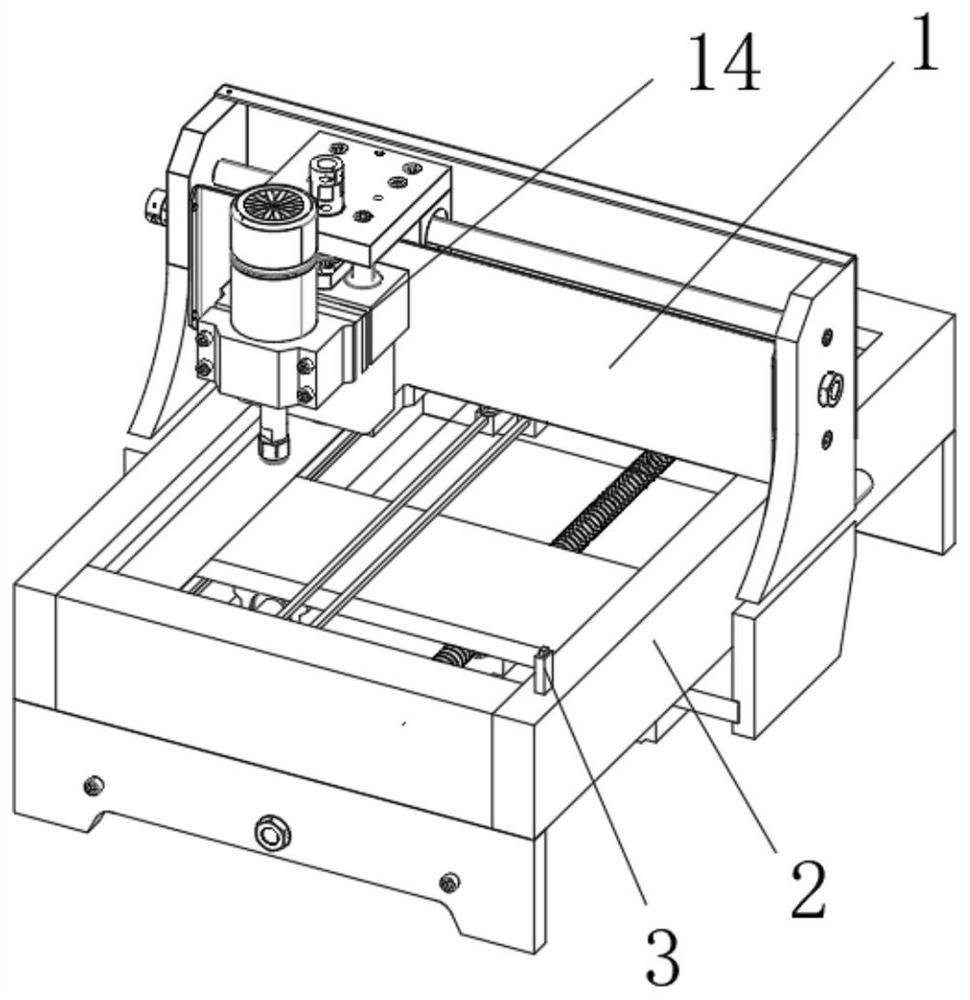

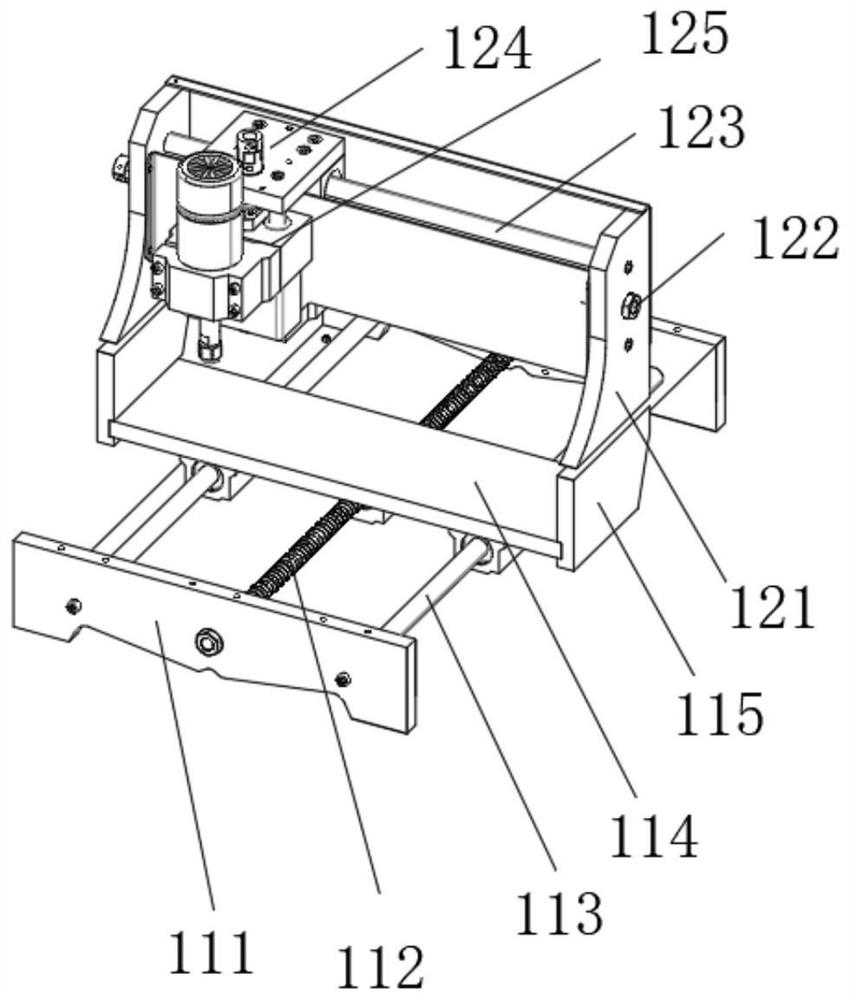

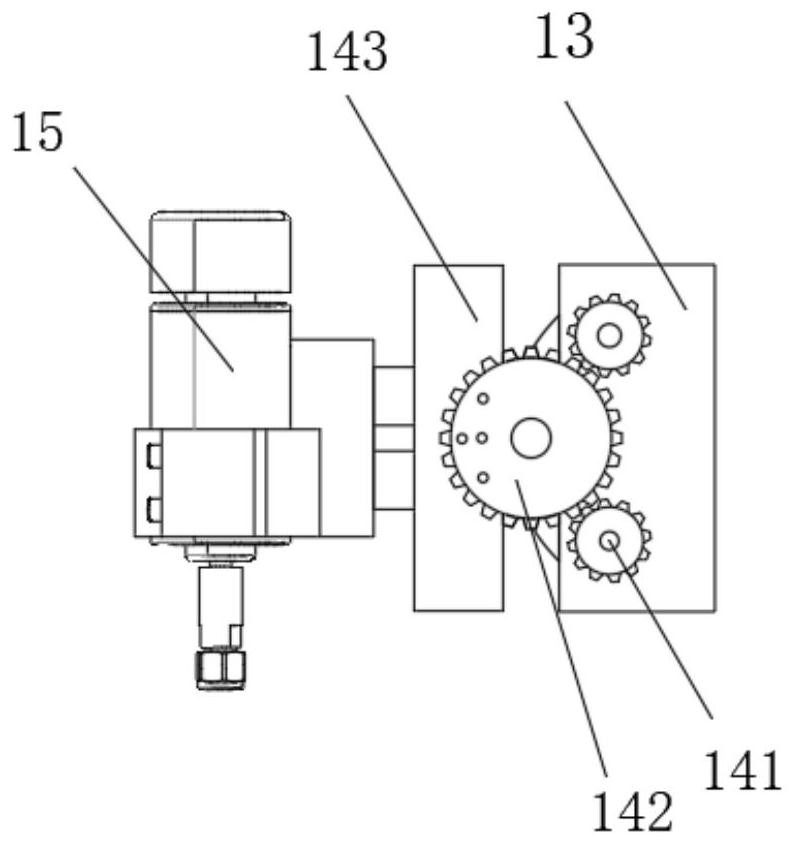

[0060] The shearing device in this embodiment preferably uses the laser component 15 to carry out customized or preset graphic cutting of the original material, and enters the three-dimensional facial spectrum data of the required image and the three-dimensional facial spectrum data of the original material to the image acquisition center, and The original material is fixed at a preset position on the positioning module 2, wherein the positioning module 2 is installed on the base of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com