Construction method of fabricated steel trestle

A construction method and technology for steel trestle bridges, which are applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of long time, complicated procedures, and inability to support the bottom of steel pipe piles in deep water for operators, and reduce the The effect of underwater construction time, improving safety, and increasing the ability to resist the scour force of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

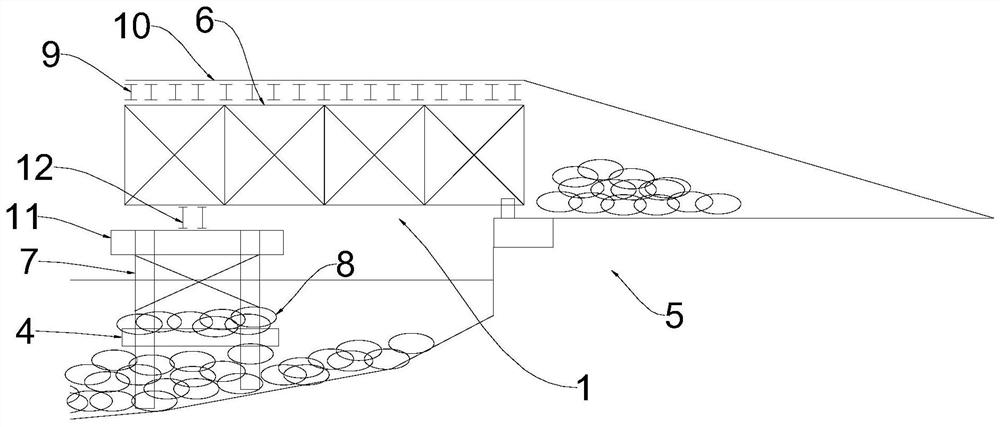

[0035] This embodiment describes a situation in which the construction method of the present invention is used to construct a steel trestle bridge on the Tuojiang River. In addition, the present invention can be applied to the construction of steel trestle bridges in various other scenarios. This embodiment is described by taking the application of bridge construction on the Tuojiang River as an example. The section of the Tuojiang River where trestle bridge construction is carried out has been surveyed as bedrock at the bottom of the riverbed, covered with river pebbles of uneven thickness, the deepest part of the river is 13m, and the shallowest part is 7m.

[0036] The construction method of the assembled steel trestle in the present embodiment comprises the following steps:

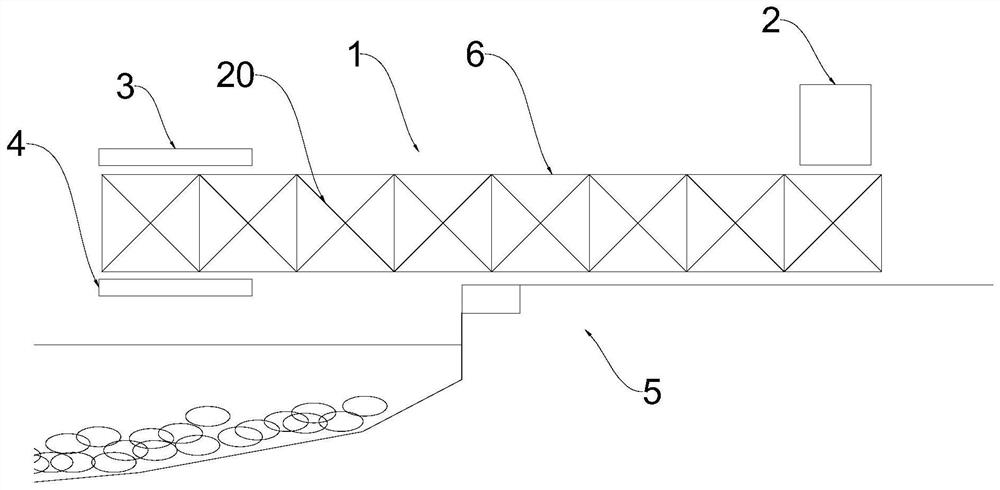

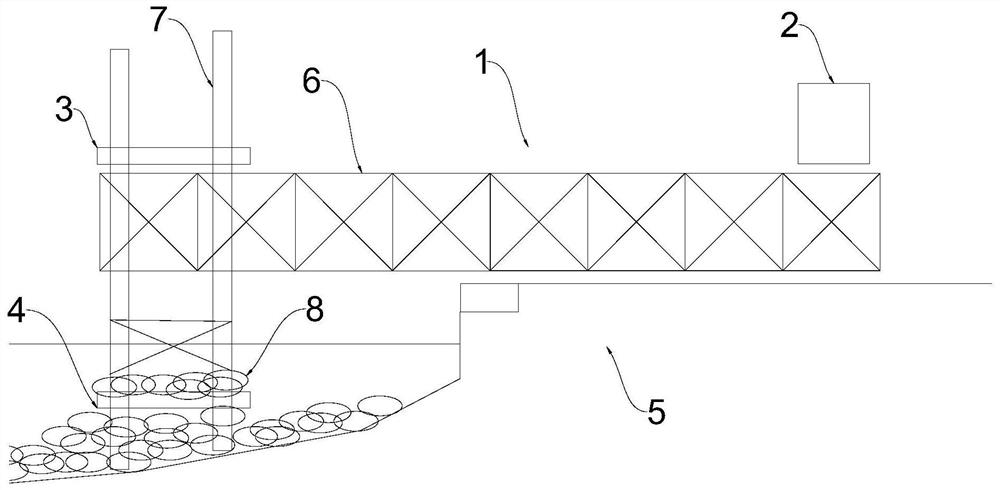

[0037] see figure 1 and Figure 6 , the present embodiment first executes step 1: leveling the site, measuring and setting out, building the bridge head joint, and installing and constructing the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com