Portal frame type arch frame transportation structure, tunnel construction device and construction method

A tunnel construction and gantry-type technology, which is applied in transportation and packaging, tunnels, tunnel linings, etc., can solve the problems of prolonging the tunnel construction time, not being suitable for tunnels with small widths, difficulties, etc., and achieve the effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

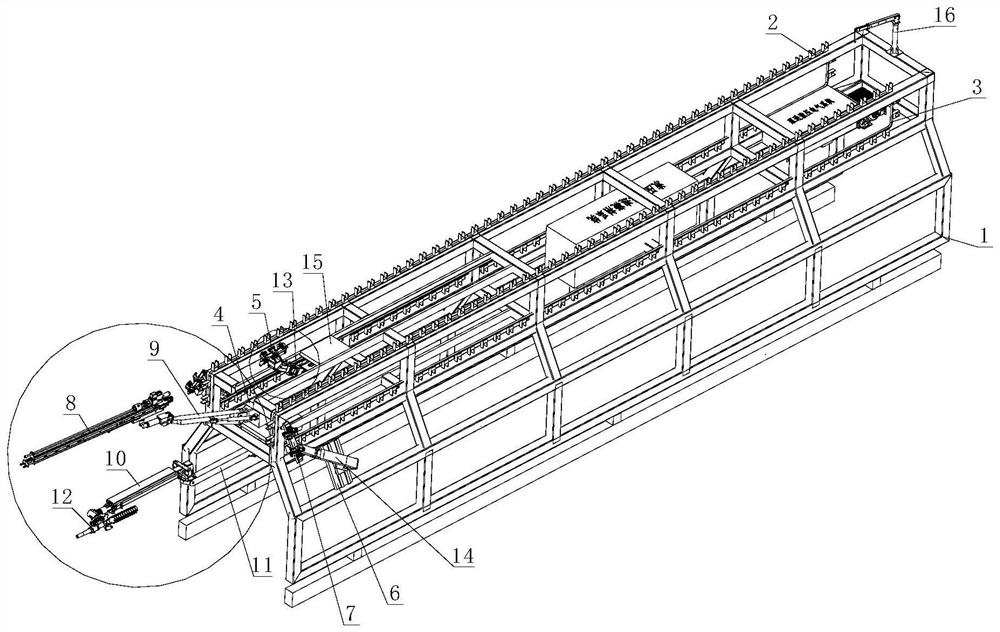

[0032] Such as Figure 1-3 As shown, a gantry-type arch transportation structure includes a gantry 1, the width of which is equivalent to the width of the tunnel, and is placed in the tunnel. The upper end of the gantry 1 is provided with a conveyor belt 3, and the conveyor belt 3 consists of Driven by the motor, the conveyor belt 3 can also be driven by a hydraulic motor to rotate relative to the door frame 1. The rotation direction of the conveyor belt 3 is from the outside of the tunnel to the inside of the tunnel, so that the arch frame is gradually transported forward. A plurality of arch support seats 2 are fixedly connected, and an arch can be placed on each arch support seat 2, and the two conveyor belts 3 are arranged symmetrically on both sides of the door frame 1, thereby ensuring the stability of the arch transportation. There is a one-to-one correspondence between the arch support seats 2 on the conveyor belt 3 . It can be understood that the arches are directly ...

Embodiment 2

[0035] A gantry type tunnel construction device, which can be directly placed in the tunnel for use during tunnel construction. With the continuous forward construction of the tunnel, the device can also be provided with a walking mechanism under it. The walking mechanism can be a crawler belt. The device can move forward continuously with the construction of the tunnel, thereby ensuring the progress of the construction.

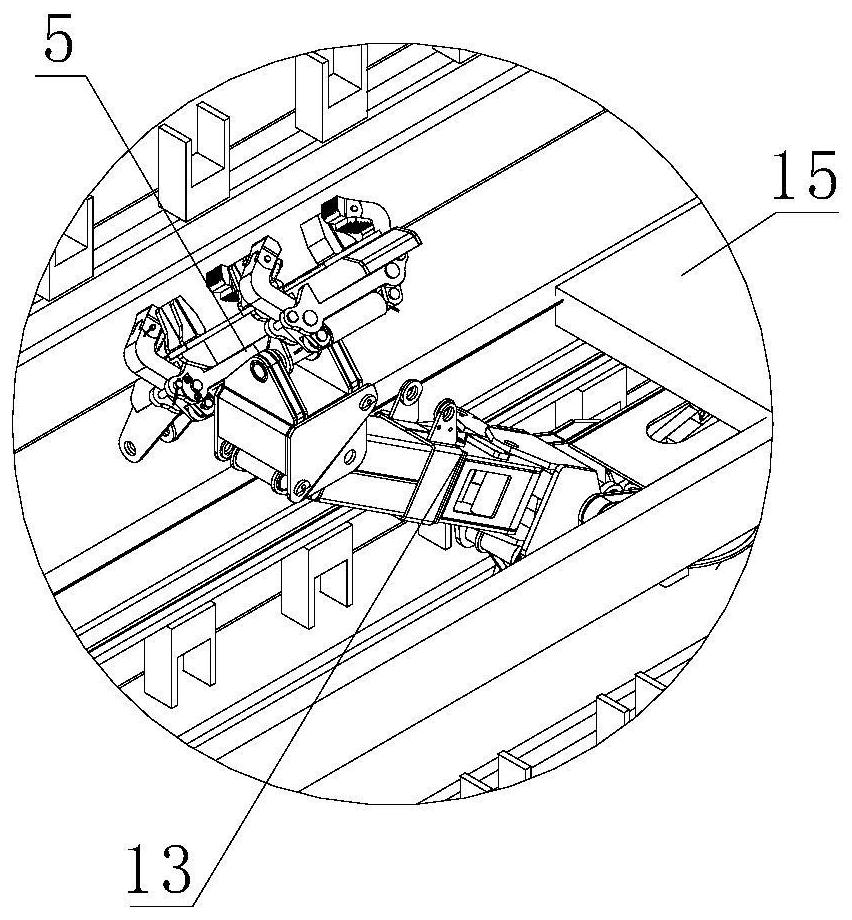

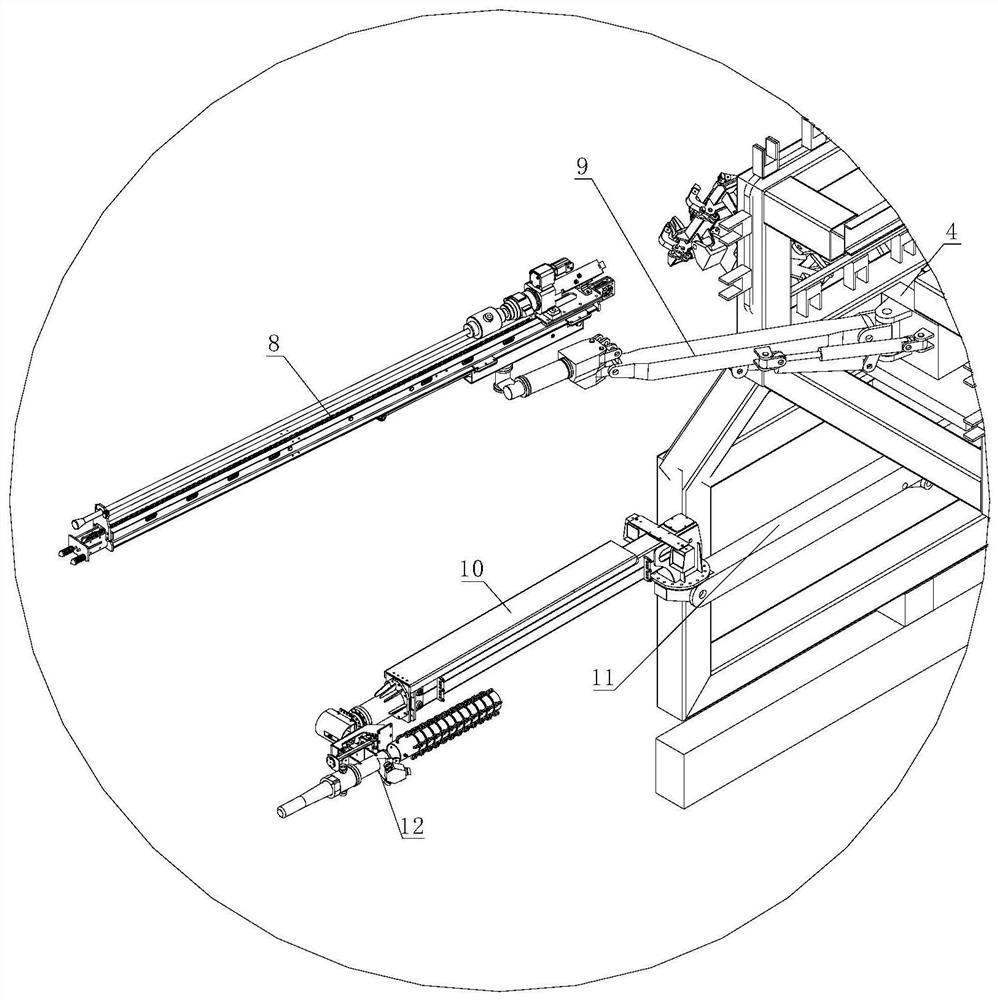

[0036] It specifically includes the above-mentioned gantry-type arch transport structure. A first moving part 15 is arranged on the upper part of the gantry 1. The first moving part 15 can be arranged on the axis of the gantry 1. The first moving part 15 is opposite to the door frame. 1 to move, the first manipulator 5 is set on the first moving part 15, the first manipulator 5 can grab the arch, the first manipulator 5 is hinged on the first moving part 15 through the first mechanical arm 13, the The first manipulator 13 is pitchable and telescopic, thereby...

Embodiment 3

[0044] The difference from the above-mentioned embodiment is that, if Figure 4-6 As shown, in this embodiment, an excavating device 17 is arranged in the portal frame 1, and the excavating device 17 is used to excavate the tunnel wall. There are methods, such as riveting, threaded connection, etc., when the excavating device 17 is not needed, the excavating device 17 can be removed; the excavating device 17 is provided with a transport device below, and the transport device is used to transport the excavated debris in the tunnel. Stones, debris, etc., are transported to the outside of the tunnel through the transport device.

[0045] The height of the rock drilling device 8 and the spraying arm 10 is lower than the height of the conveyor belt 3; the excavating device 17 is a roadheader.

[0046] The transportation device includes a conveyor belt 18, the length of which is equivalent to that of the door frame 1, and transports the excavated debris out of the tunnel; The slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com