Deslagging valve and filter with same

A slag discharge valve and filter technology, which is applied in the direction of filtration separation, fixed filter element filter, valve operation/release device, etc. slag, ensure thoroughness, and improve the effect of filter press efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

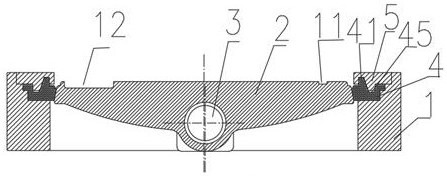

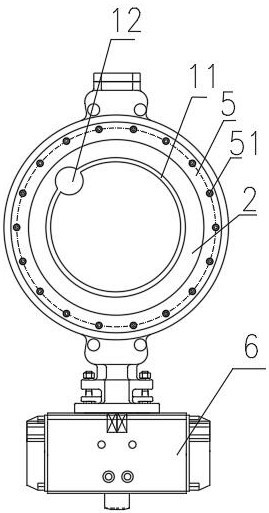

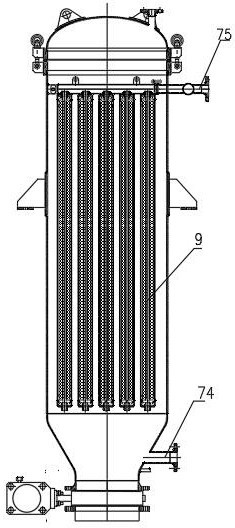

[0021] The invention discloses a slag discharge valve combined Figure 1-Figure 2 As shown, it is the same as the prior art, including a valve body 1 and a valve plate 3 placed in the valve body 1 through a valve stem 3 . One end of the valve stem 3 is connected to a driving mechanism 6 arranged outside the valve body 1 , and in this embodiment, the driving mechanism 6 is an air cylinder. The valve plate 3 is driven to rotate by the cylinder to open or close the slag discharge valve.

[0022] Different from the prior art, the back of the valve plate 2 is arranged in an arc shape, and is eccentrically arranged with the valve stem 1, and the eccentric distance is 1-2mm. A groove 11 is provided around the upper surface of the valve plate 2 , and the groove 11 communicates with a counterbore 12 provided on the valve plate 2 . The counterbore 12 and the groove 11 are arranged on the same surface of the valve plate 2 . In this embodiment, the centerline of the groove 11 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com