Composite mixed submerged-arc welding flux and welding method thereof

A welding method and a technology of sintering flux, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of not meeting the mechanical performance requirements and high cost, and achieve the effect of improving welding process performance, low cost and reducing harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

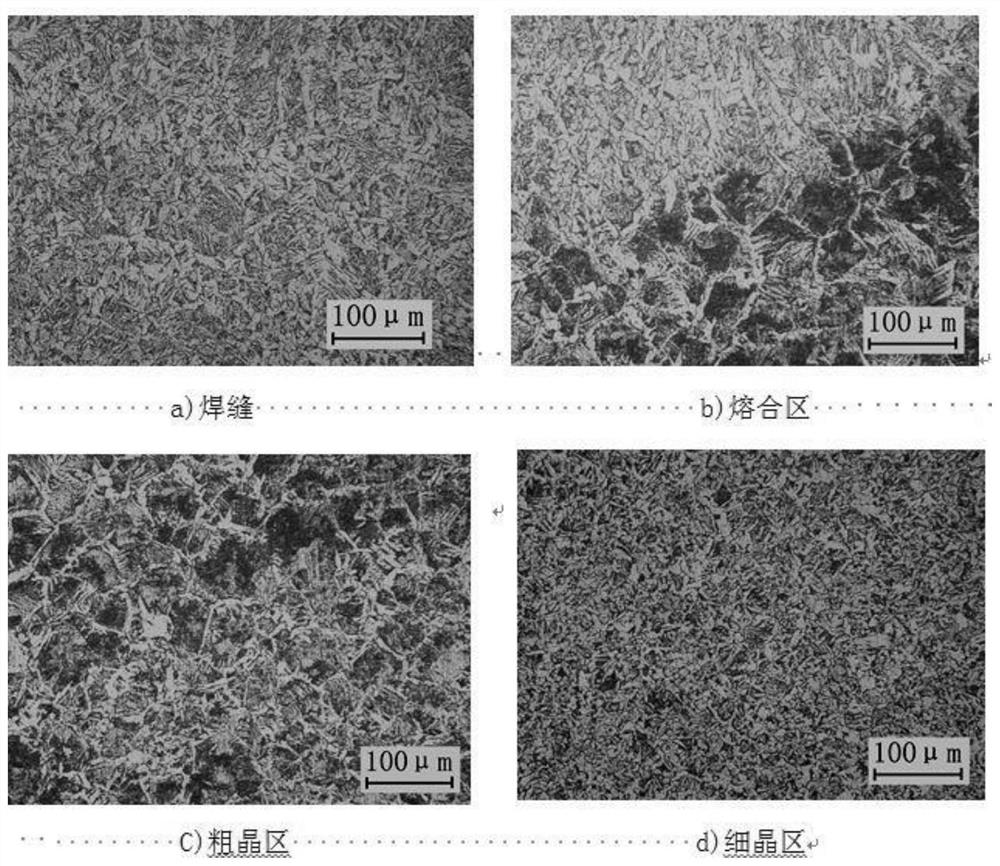

Image

Examples

Embodiment 1

[0022] The composite mixed submerged arc welding flux provided in this example has raw materials of sintering flux HJ431 and smelting flux SJ101, and the weight ratio is 7:1.

Embodiment 2

[0024] The composite mixed submerged arc welding flux provided in this example is made of raw materials of sintering flux HJ431 and melting flux SJ101, and the weight ratio is 5.5:1.

Embodiment 3

[0026] The composite mixed submerged arc welding flux provided in this example is made of raw materials of sintering flux HJ431 and melting flux SJ101, and the weight ratio is 8:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com