Hydraulic valve port submerged jet erosion visual experiment system and experiment method

An experimental system, hydraulic valve technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of poor uniformity of oil particles and pump wear, etc., to achieve a wide range of use, improve flexibility, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

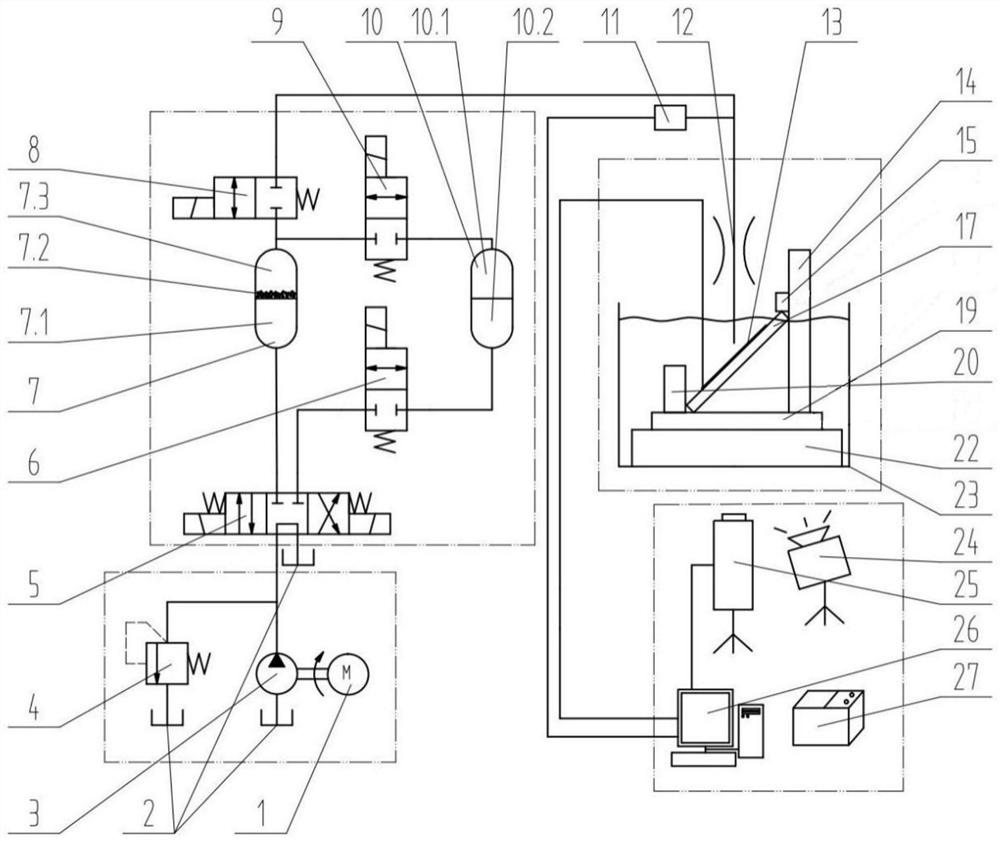

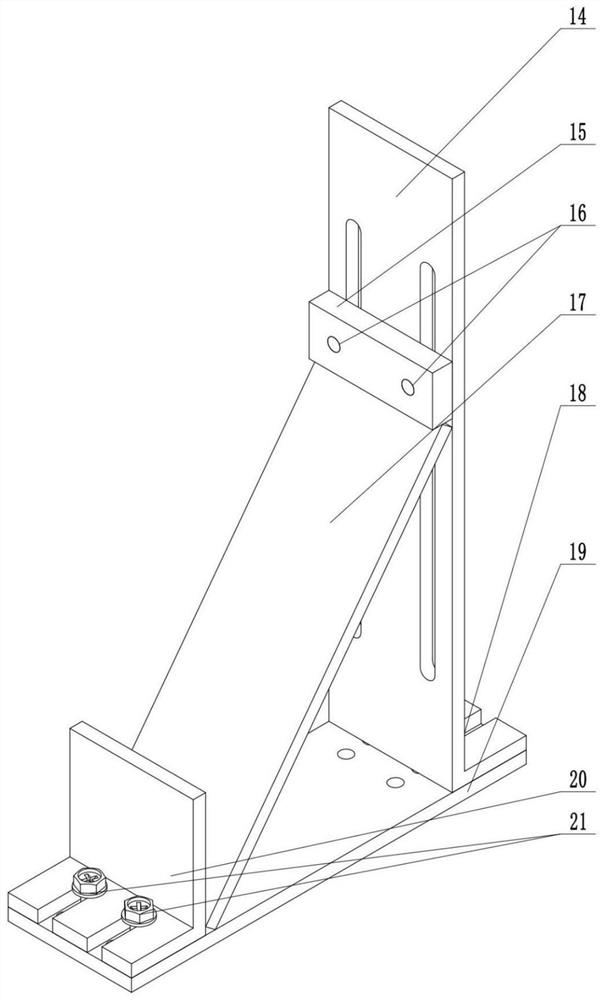

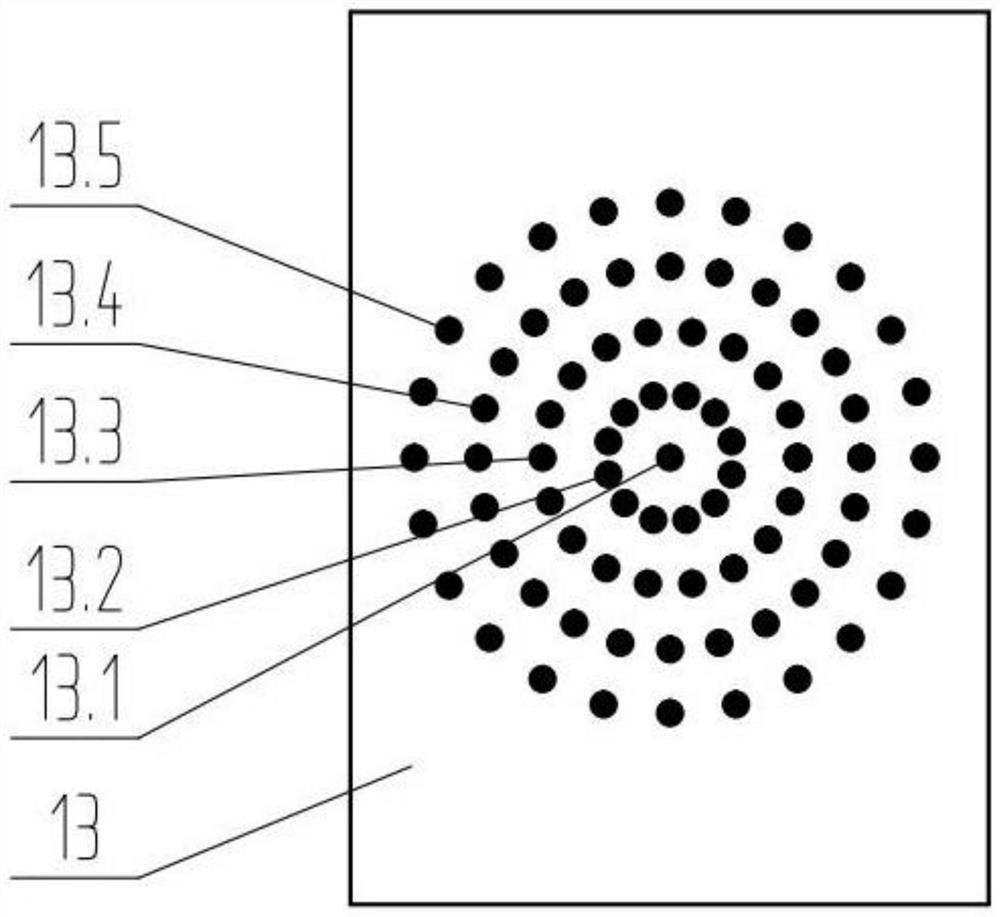

[0063] Such as figure 1 As shown, this embodiment provides a hydraulic valve port submerged jet erosion visualization experiment system, specifically a particle (test particle)-wall surface (the sprayed plate surface of the baffle 17) erosion during the hydraulic valve port submerged jet process The visualization experiment system includes a power unit, a particle-oil mixing unit, a particle-oil submerged jet unit, a measurement unit and a particle recovery unit. in:

[0064] The power unit includes a motor 1, a pump 3, an oil tank 2 and an overflow valve 4, the motor 1 is connected to the pump 3, the inlet of the pump 3 is connected to the oil tank 2, the outlet of the pump 3 is connected in parallel with the overflow valve 4, and the outlet of the overflow valve 4 The outlet is connected back to fuel tank 2. Wherein, the pump 3 is preferably a gear pump, and the oil tank 2 connected to the pump 3 and the oil tank 2 connected to the outlet of the overflow valve 4 may be the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com