Simple eutectic LED chip structure and manufacturing method thereof

An LED chip and manufacturing method technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult eutectic, increased leakage probability, and high cost, and achieves reduced leakage probability, reduced eutectic difficulty, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

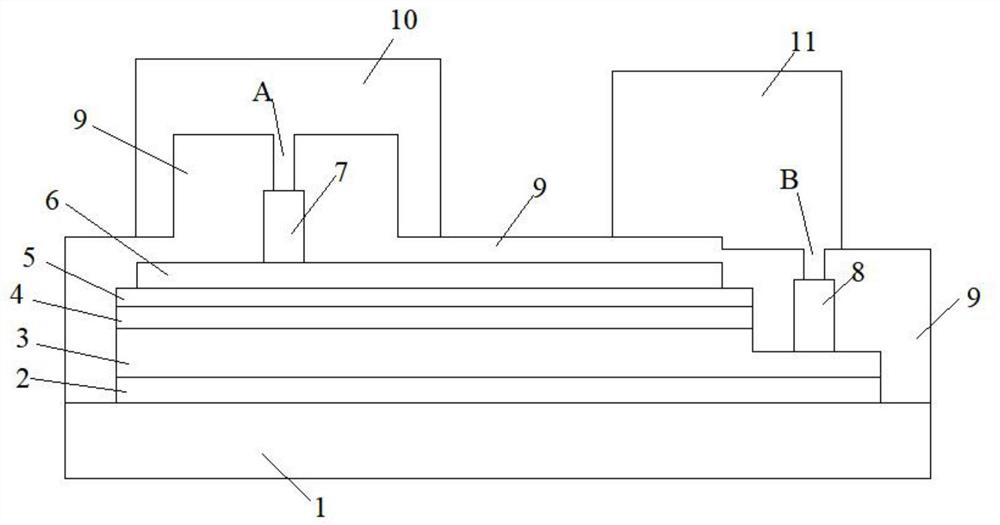

[0035] see figure 1 , a simple eutectic LED chip structure, including a P electrode 7, an N electrode 8, a Bragg reflective layer 9, a P welding layer 10, and an N welding layer 11; the P electrode 7 is arranged below the Bragg reflective layer 9, and Connect to the P welding layer 10 through the first through hole A that penetrates the Bragg reflective layer 9; the N electrode 8 is arranged below the Bragg reflective layer 9, and connects to the N solder layer through the second through hole B that penetrates the Bragg reflective layer 9 11 connections;

[0036] The electrode structures of the P welding layer 10 and the N welding layer 11 are Cr layer, Al layer, (Ti layer / Pt layer) n, Au layer and Sn layer which are sequentially stacked on the Bragg reflection layer 9, wherein, Ti Layer / Pt layer means the Ti layer and the Pt layer which are stacked in sequence, n means the number of repetitions of the stacked Ti layer and the Pt layer, and the value of n is 2.

[0037] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com