Preparation method of copper flexible connecting piece for new energy automobile battery

A new energy vehicle and connector technology, which is applied in the field of preparation of copper soft connectors for new energy vehicle batteries, can solve problems such as insufficient anti-corrosion performance and cumbersome preparation process, and achieve improved anti-corrosion effect and good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

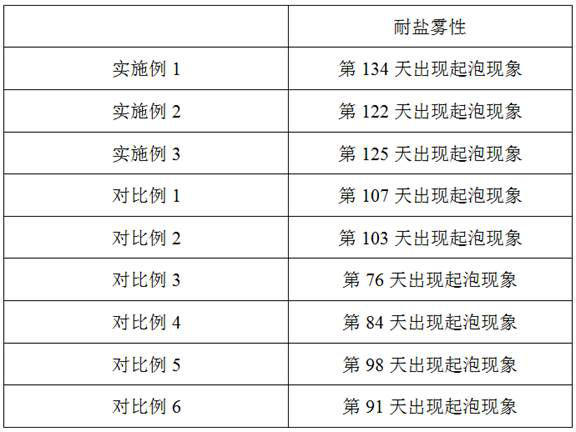

Examples

Embodiment 1

[0049] A method for preparing a copper soft connector for a new energy vehicle battery, comprising the following steps:

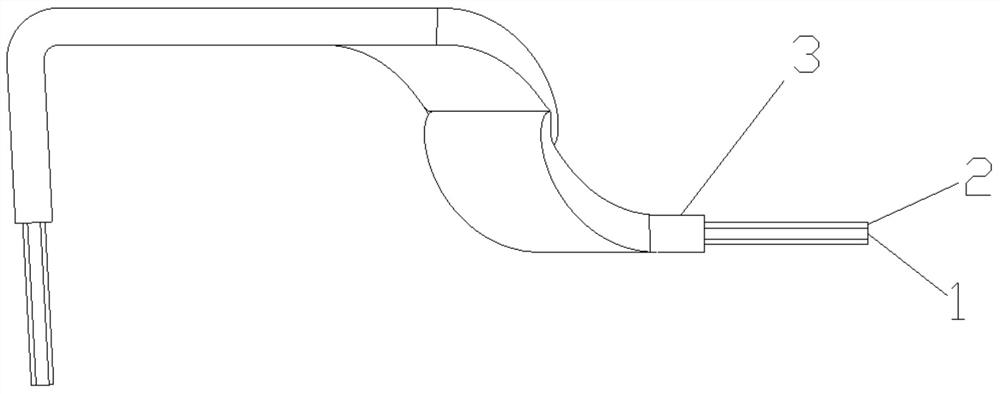

[0050] S1. Fix the conductive metal sheet 2 on the upper and lower sides of the conductive metal foil 1, form a connecting piece by welding with a polymer diffusion machine, and then perform polishing treatment; the fixing can be fixed by a clamp or by other methods;

[0051] S2. Bending and forming the connecting piece so that the connecting piece forms a wavy structure, setting the heat-shrinkable sleeve 3 on the periphery of the connecting piece, and passing through a tunnel furnace to obtain a copper flexible connecting piece for a new energy vehicle battery;

[0052] The polishing treatment is performed by using a polishing treatment liquid.

[0053] The conductive metal sheet 2 is a nickel sheet, the conductive metal foil 1 is copper foil, and the copper foil is formed by superimposing T2 red copper foil with a thickness of 0.1mm, the nickel sheet is ...

Embodiment 2

[0072] A method for preparing a copper soft connector for a new energy vehicle battery, comprising the following steps:

[0073] S1. Fix the conductive metal sheet 2 on the upper and lower sides of the conductive metal foil 1, weld the connecting piece through a polymer diffusion machine, and then perform polishing treatment;

[0074] S2. Bending and forming the connecting piece so that the connecting piece forms a wavy structure, setting the heat-shrinkable sleeve 3 on the periphery of the connecting piece, and passing through a tunnel furnace to obtain a copper flexible connecting piece for a new energy vehicle battery;

[0075] The polishing treatment is performed by using a polishing treatment liquid.

[0076] The conductive metal sheet 2 is a nickel sheet, the conductive metal foil 1 is copper foil, and the copper foil is formed by superimposing T2 red copper foil with a thickness of 0.1mm, the nickel sheet is N6 pure nickel sheet, the The thickness of the copper foil is...

Embodiment 3

[0088] A method for preparing a copper soft connector for a new energy vehicle battery, comprising the following steps:

[0089] S1. Fix the conductive metal sheet 2 on the upper and lower sides of the conductive metal foil 1, weld the connecting piece through a polymer diffusion machine, and then perform polishing treatment;

[0090] S2. Bending and forming the connecting piece so that the connecting piece forms a wavy structure, setting the heat-shrinkable sleeve 3 on the periphery of the connecting piece, and passing through a tunnel furnace to obtain a copper flexible connecting piece for a new energy vehicle battery;

[0091] The polishing treatment is performed by using a polishing treatment liquid.

[0092] The conductive metal sheet 2 is a nickel sheet, the conductive metal foil 1 is copper foil, and the copper foil is formed by superimposing T2 red copper foil with a thickness of 0.1mm, the nickel sheet is N6 pure nickel sheet, the The thickness of the copper foil is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com