Novel jet machining and detection integrated precision equipment

A technology of precision equipment and spraying mechanism, which is applied in metal processing equipment, abrasive spraying machine tools, used abrasive processing devices, etc., and can solve problems such as ensuring polishing quality, failing to meet finishing requirements, and failing to meet processing accuracy. , to achieve the effect of improving reliability and stability, ensuring no sub-surface damage, and reducing concentricity errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

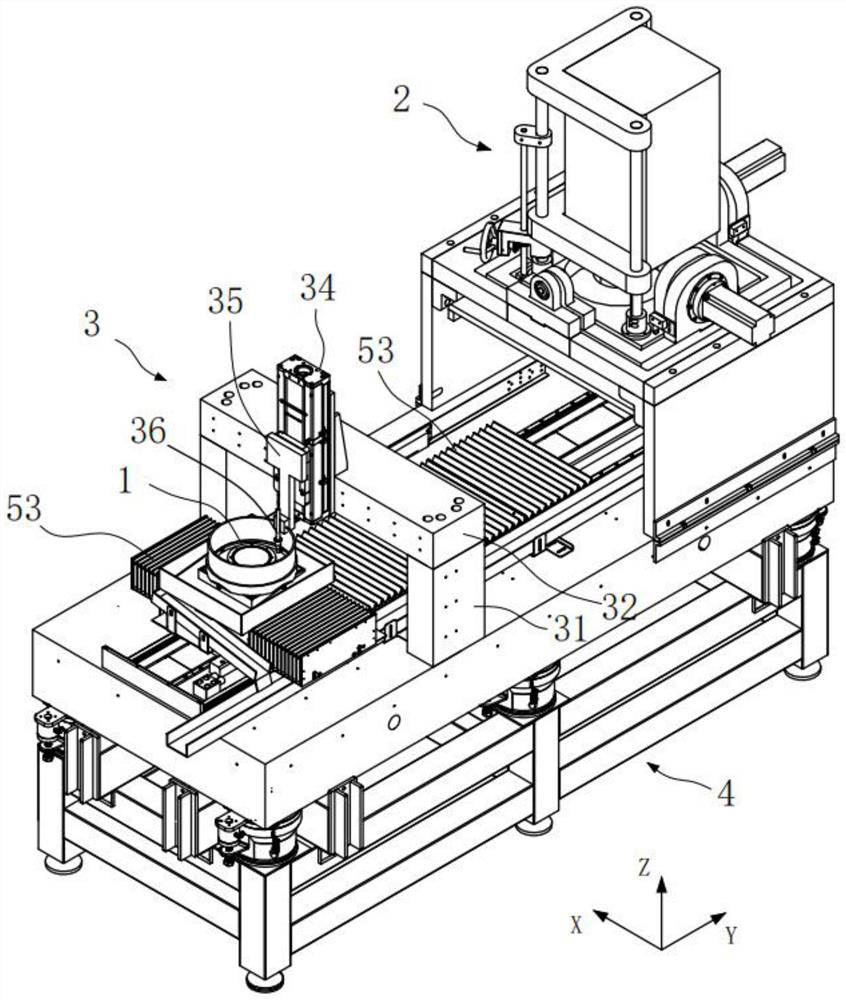

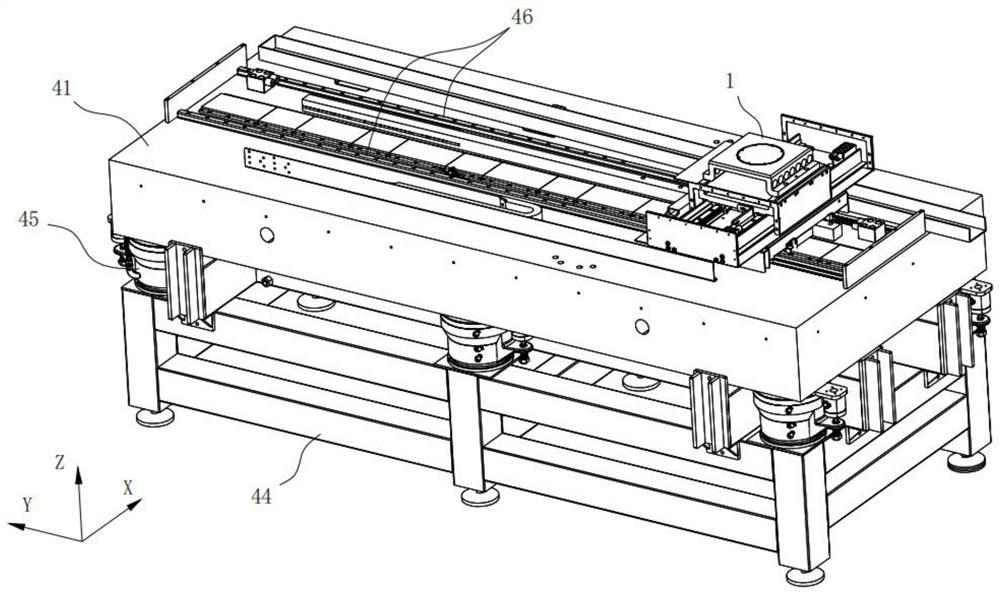

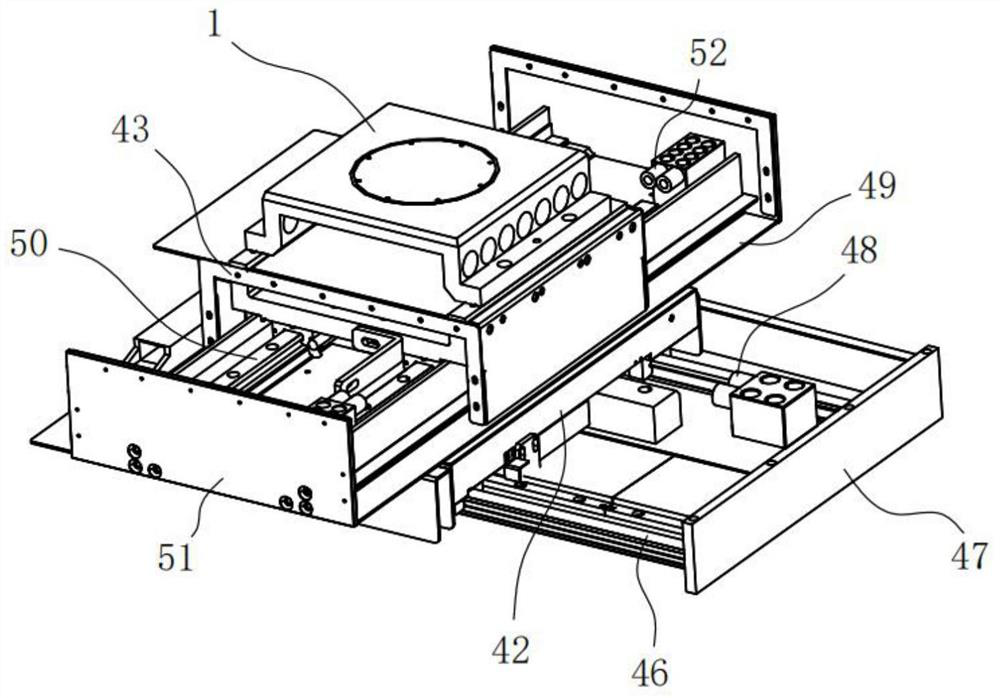

[0032] see figure 1 As shown, the present invention discloses a new integrated precision equipment for spray processing and detection, which includes a workbench 1 for loading workpieces, a measuring mechanism 2 for detecting workpieces, and for measuring workpieces according to the detection results. The spraying mechanism 3 and the moving mechanism 4 for spraying processing, the worktable 1, the measuring mechanism 2 and the spraying mechanism 3 are all arranged on the moving mechanism 4 and integrated into one body, and the moving mechanism 4 can respectively drive the working table 1 to move back and forth to the measuring mechanism 2 and below the injection mechanism 3, the present invention also includes a host computer, which is connected to the measurement mechanism 2, the injection mechanism 3, and the motion mechanism 4 respectively.

[0033] In the present invention, the length direction of the platform is set as the Y-axis direction, and the width direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com