Chip making equipment for food processing factory

A technology for processing plants and french fries, which is applied in the field of french fries making equipment, and can solve problems such as high energy consumption and hand injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

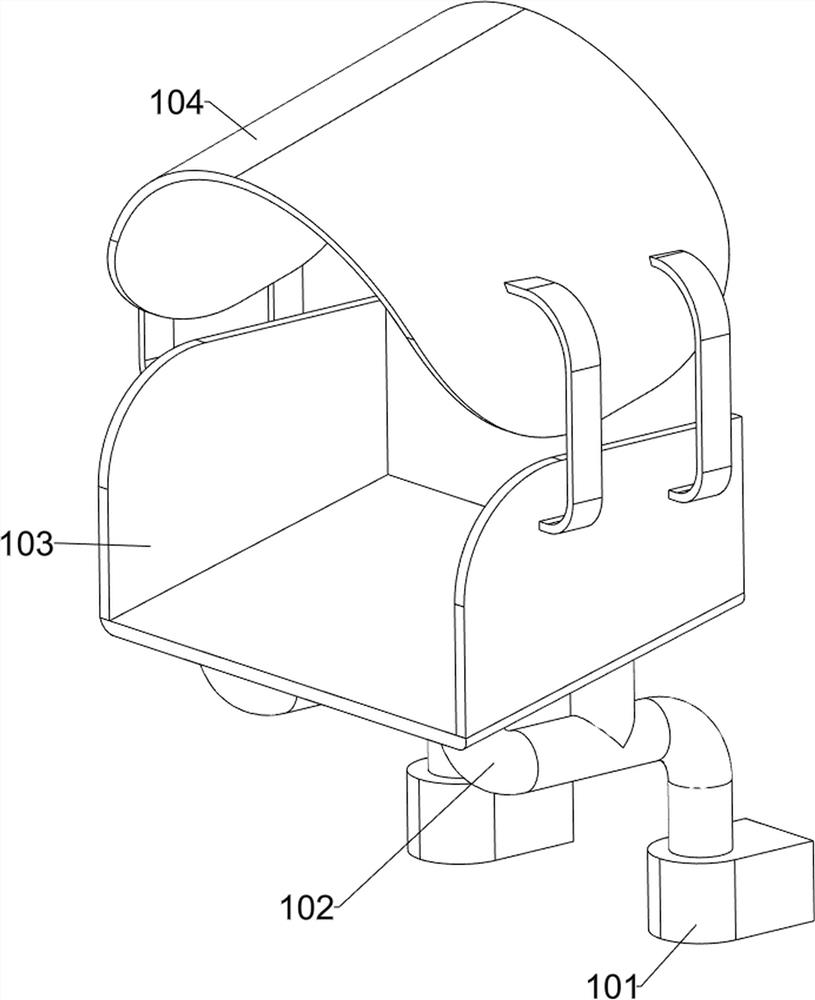

[0029] A kind of French fries making equipment for food processing factory, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a bottom plate 1, a support frame 2, a material holder 3, a replaceable tool holder 4, a first mounting frame 5, a cylinder 6, a first guide frame 7, a push block 8, a positioning mechanism 9 and a material guide assembly 10 , the left part of the bottom plate 1 is provided with a support frame 2, the upper part of the support frame 2 is provided with a material holder 3, the left side of the material holder 3 is slidingly provided with a replaceable knife holder 4, and the right side of the top of the bottom plate 1 is provided with a first installation frame 5 , the first mounting frame 5 is far away from the replaceable knife rest 4, the upper part of the first mounting frame 5 is provided with a cylinder 6, and the telescopic rod of the cylinder 6 is provided with a first guide frame 7, and the first guide frame 7 is plac...

Embodiment 2

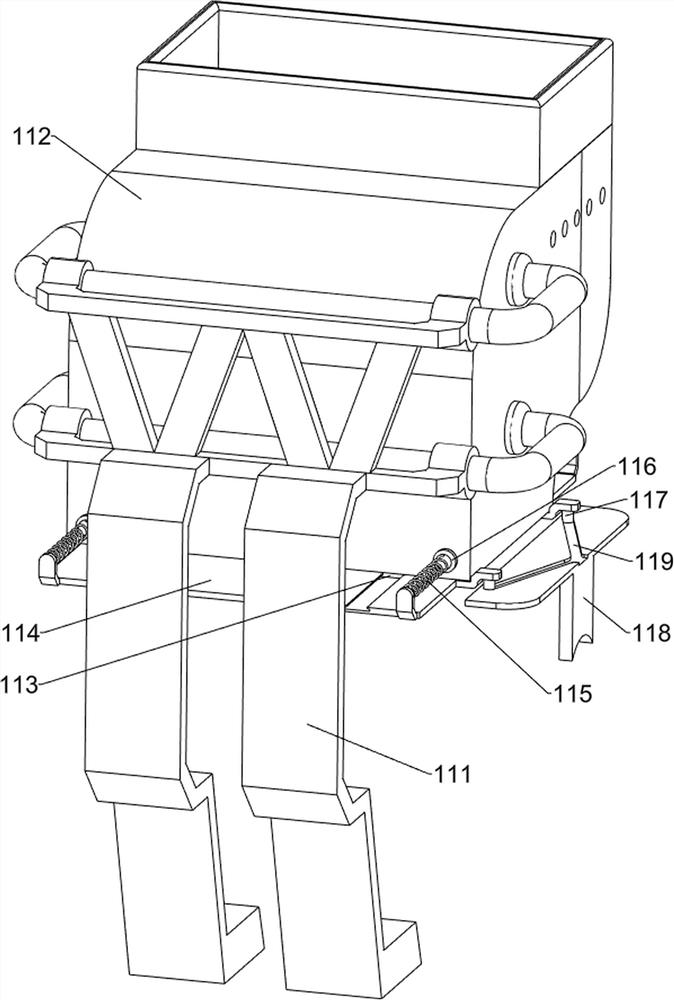

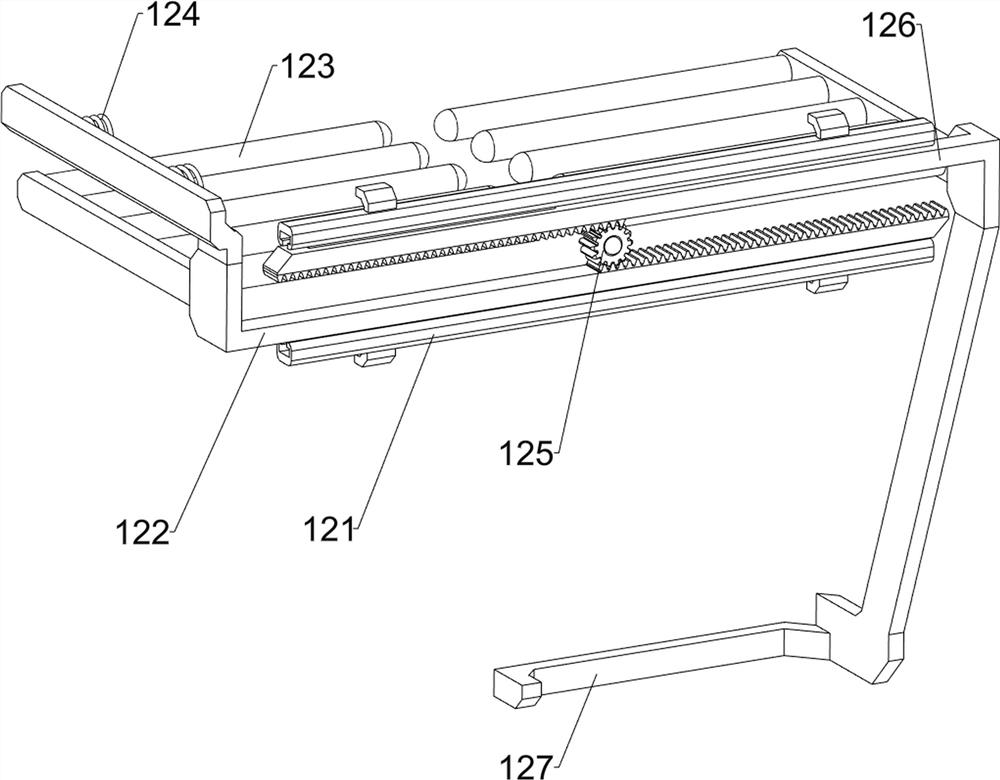

[0035] On the basis of Example 1, such as figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, a feeding mechanism 11 is also included, and the feeding mechanism 11 includes a second mounting frame 111, a storage box 112, a second block 113, a partition 114, a second return spring 115, a second connecting seat 116, a trigger Rod 117 and connecting frame 118, bottom plate 1 top left side is provided with second installation frame 111, and the second installation frame 111 top is provided with material storage box 112, and the bottom and top of described material storage box 112 are openings and are arranged, and material storage Both the front and rear sides of the bottom of the box 112 are symmetrically provided with second clamping blocks 113, and the two adjacent second clamping blocks 113 are slidingly provided with partitions 114, and the partitions 114 are symmetrically provided with second return springs. 115, the front and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com