Measurement adjusting mechanism of jet machining precision equipment

A technology of adjustment mechanism and precision equipment, applied in metal processing equipment, abrasive jet machine tools, measuring devices, etc., can solve the problems of ensuring polishing quality, large deviation between measurement and processing, and insufficient measurement accuracy, and improve processing quality and efficiency. , good reliability, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

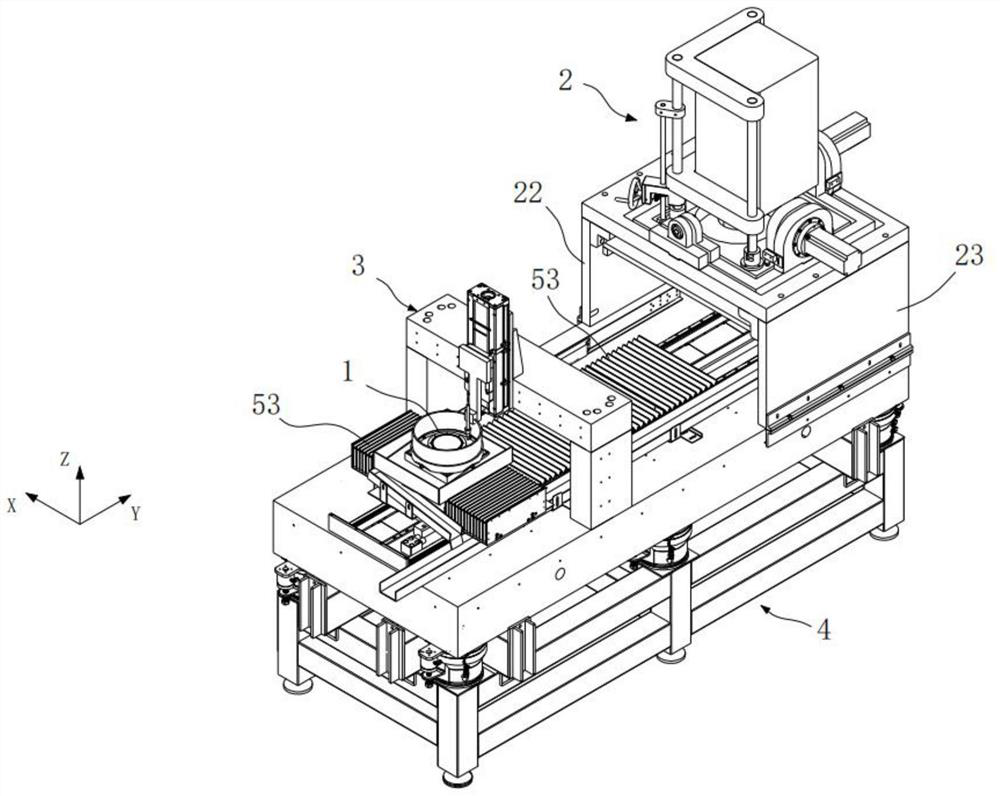

[0022] see figure 1 As shown, a spray processing precision equipment includes a workbench 1 for loading workpieces, a measurement and adjustment mechanism 2 for measuring workpieces, a spray mechanism 3 for spray processing workpieces according to the detection results, and a movement mechanism 4. The workbench 1, the measurement adjustment mechanism 2 and the injection mechanism 3 are all arranged on the movement mechanism 4 and integrated into one body. The movement mechanism 4 can respectively drive the workbench 1 to move back and forth to the bottom of the measurement adjustment mechanism 2 and the injection mechanism 3. The invention also includes a host computer, which is respectively connected with the measurement and adjustment mechanism 2, the injection mechanism 3 and the movement mechanism 4.

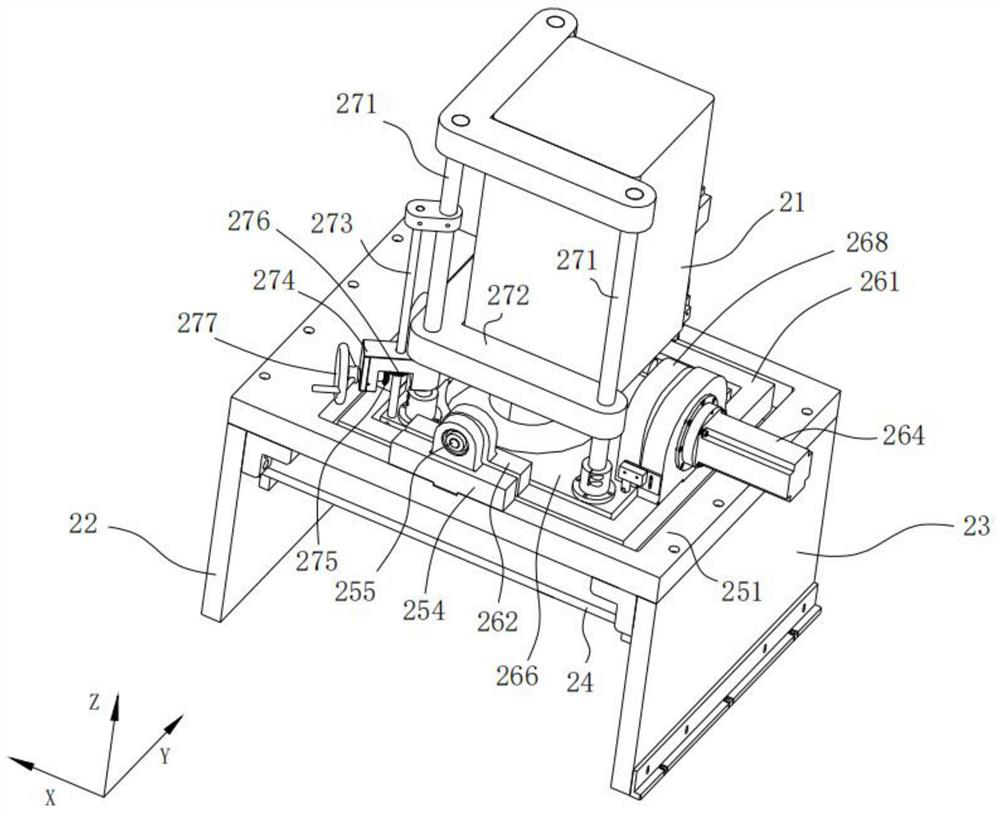

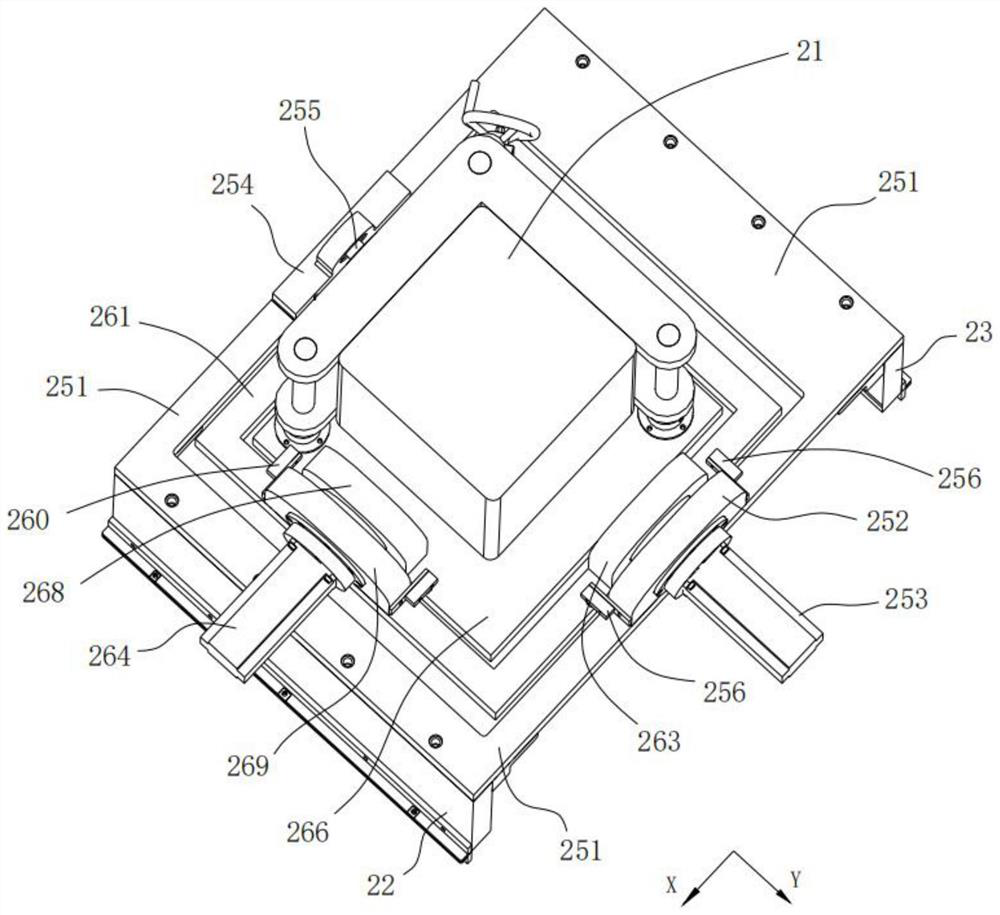

[0023] The measurement adjustment mechanism 2 claimed in the present invention, see Figure 2 to Figure 4 As shown, the measurement adjustment mechanism 2 includes a laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com