Surface difference measuring device for excavator outer part and measuring method

A technology for measuring equipment and exterior parts, applied in the field of excavator exterior parts measuring systems, can solve the problems of small span, high price, inability to measure quickly and accurately, and achieve the effects of improving test accuracy and reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

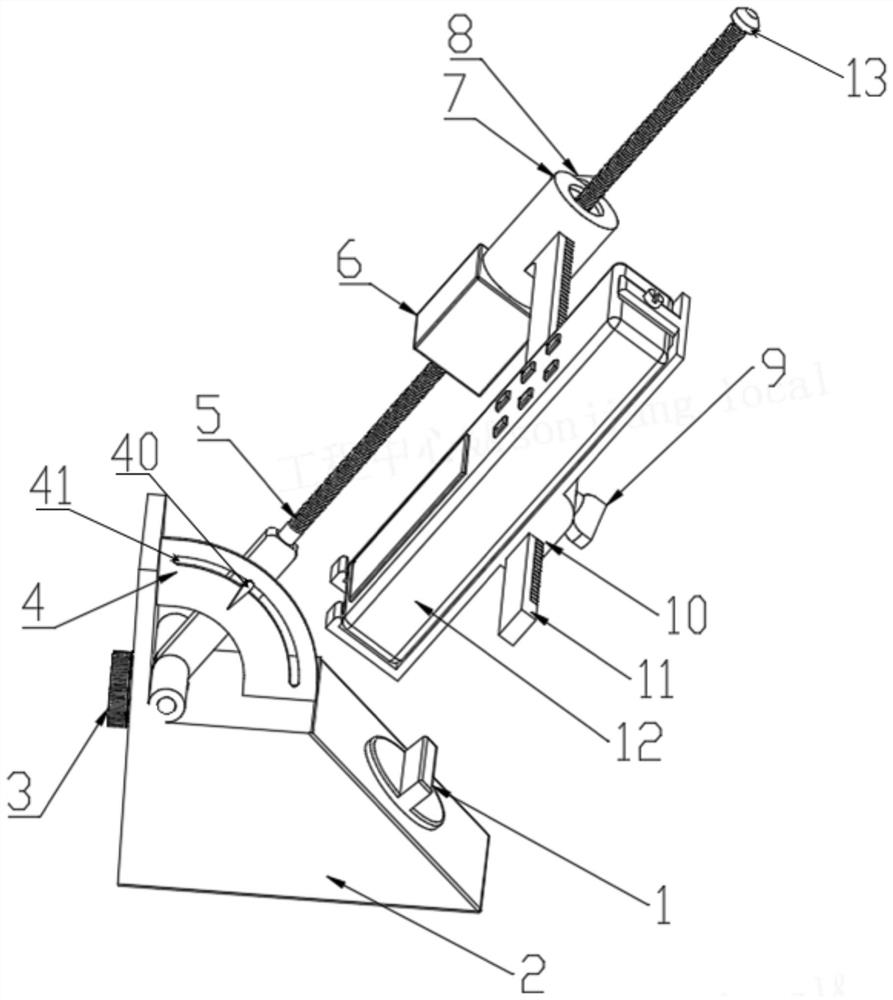

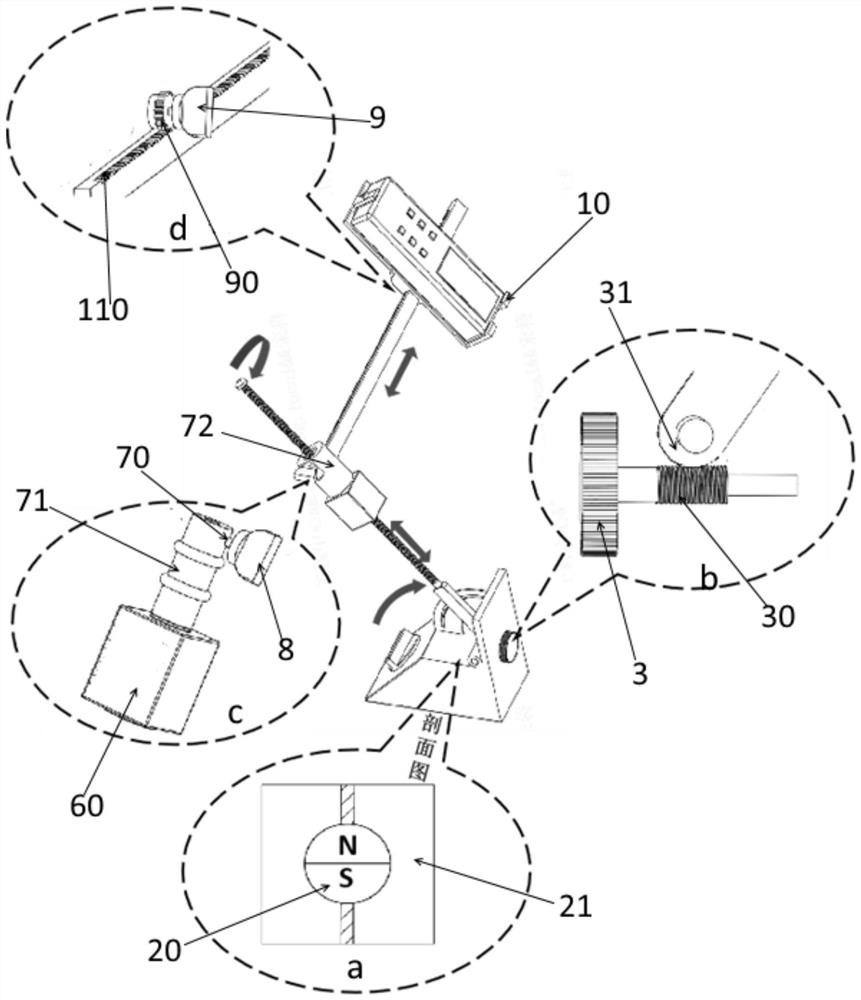

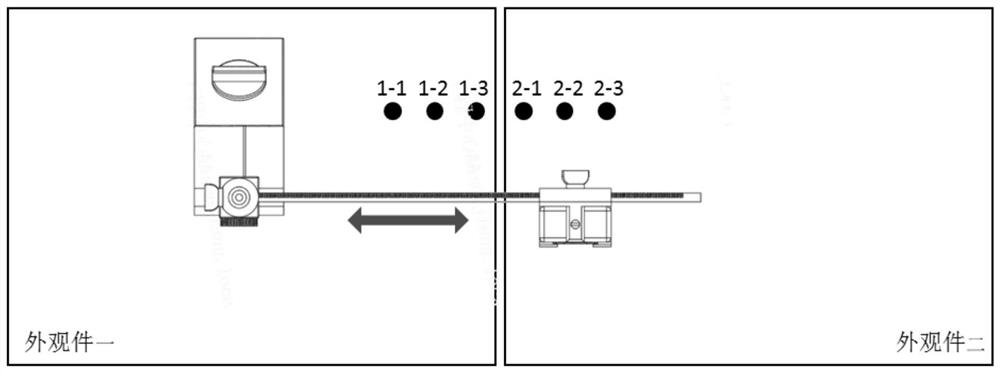

[0033] to combine Figure 1 to Figure 2 The surface difference measuring equipment for the exterior part of the excavator shown includes: a magnetic control switch 1, a magnetic base body 2, a magnet 20, a magnetic force regulating mechanism 21, a first knob 3, a worm 30, a column turbine 31, and an angle indicating dial 4 , pointer 40, curved slide rail 41, column 5, integrated control module 6, motor 60, bearing mechanism 7, screw rod 70, bearing inner ring 71, bearing outer ring 72, second knob 8, third knob 9, gear 90 , bracket 10, beam 11, rack 110, laser range finder 12, limit block 13.

[0034] Wherein, the magnetic base body 2 includes: a magnetic control switch 1 , a magnet 20 , and a magnetic force regulating mechanism 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com