A two-stage mobilenet-based defect detection method for bathroom ceramics

A technology for defect detection and ceramics, applied in neural learning methods, image analysis, image enhancement, etc., can solve the problems of detection speed requirements, detection accuracy requirements, etc., to meet the requirements of detection speed, good detection effect, and high detection speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Embodiment 1: A method for detecting defects of bathroom ceramics based on two-stage MobileNet in this embodiment includes the following steps:

[0019] Step 1: Build and train a defect localization network to obtain a trained defect localization network, including the following steps:

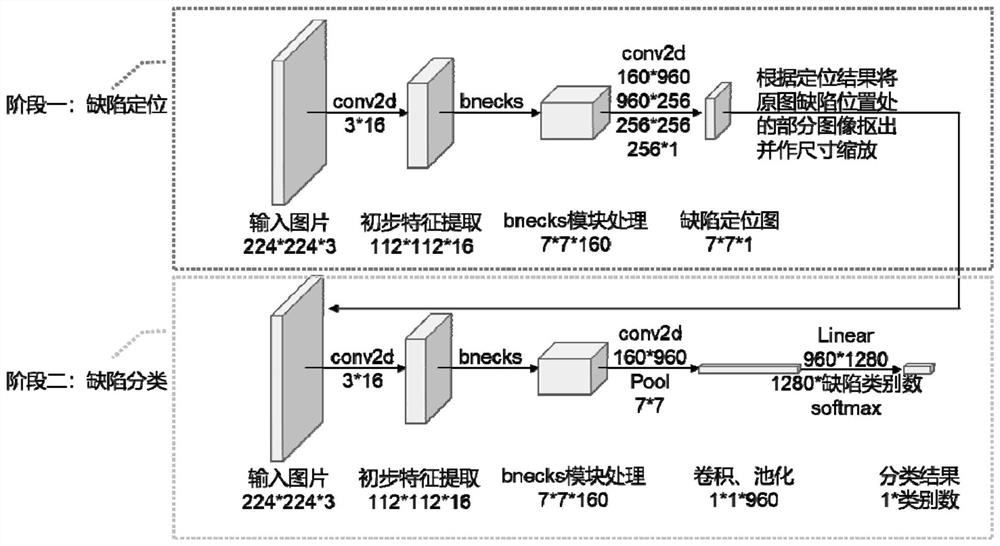

[0020] Step 11. Build a defect location network (such as figure 1 ):

[0021] The defect localization network includes: a front-stage feature extraction network and a three-layer convolutional network of the defect localization network;

[0022] The front-level feature extraction network of the defect localization network adopts the backbone network of MobileNetV3;

[0023] The backbone network of MobileNetV3 includes: a pilot convolution operation (3*16 convolution, data normalization, hswish activation), a bneck structure (including fifteen block components, each block component is composed of three layers of spinning cones. Shaped convolution operation module) and a tail convoluti...

Embodiment

[0058] In this embodiment, the defect samples collected at the production site of sanitary ceramics are used to test the effectiveness of the method. The defect types and the number of samples are shown in Table 1, and the size of the sample is 9.6 million pixels. During the testing process, 60% of the original data is used to construct the training set, and the remaining 40% of the original data is used as the test set. The calculation formula of the detection accuracy is as follows:

[0059]

[0060] The test results are shown in Table 2. The average detection frame rate reached 18FPS.

[0061] Table 1 Defect data statistics table

[0062]

[0063] Table 2 Defect detection accuracy statistics table

[0064]

[0065] It can be seen that for the defects of sanitary ceramics, the present invention not only has a high detection accuracy, but also has a detection speed that can meet the needs of the production site.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com