Detection method of impurities in polydioxanone

A polydioxanone and detection method technology, applied in the field of analytical chemistry, can solve the problems of inapplicability to routine detection of production samples, high price and high cost of hexafluoroisopropanol, and avoid inaccurate and accurate test results Good effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

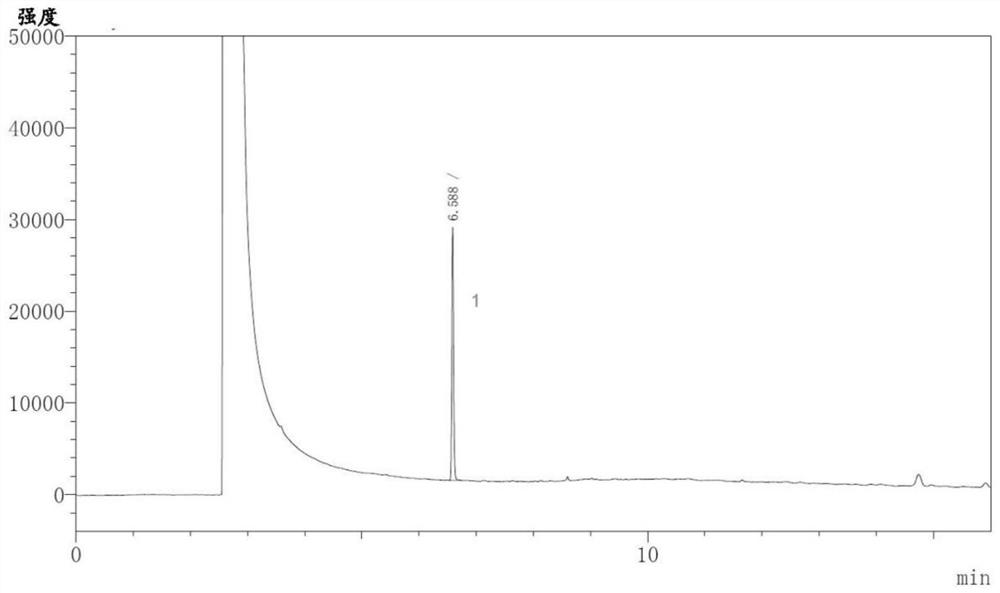

Embodiment 1

[0039] Since the amount of impurities remaining in the polydioxanone is very little or not, in order to verify that the detection method of the present invention can effectively detect possible trace impurities, a known amount of impurities was added to the test sample as an additive. Standard test sample, by comparing the detected content of each impurity in the spiked test sample and the known addition amount, calculate the recovery rate, and verify the accuracy of this detection method. Meanwhile, in this embodiment, the detection results of the method of the present invention and the original method are compared to verify the consistency of the detection results of the two methods.

[0040] Polydioxanone sample: provided by Liaoning Yuanda Nuokang Biopharmaceutical Co., Ltd.

[0041] Instrument: Shimadzu gas chromatograph (GC-2010plus, workstation: GC Solution).

[0042]Chromatographic conditions: capillary column (30×0.25mm, 1.4μm) with 6% cyanopropylbenzene+94% methyl p...

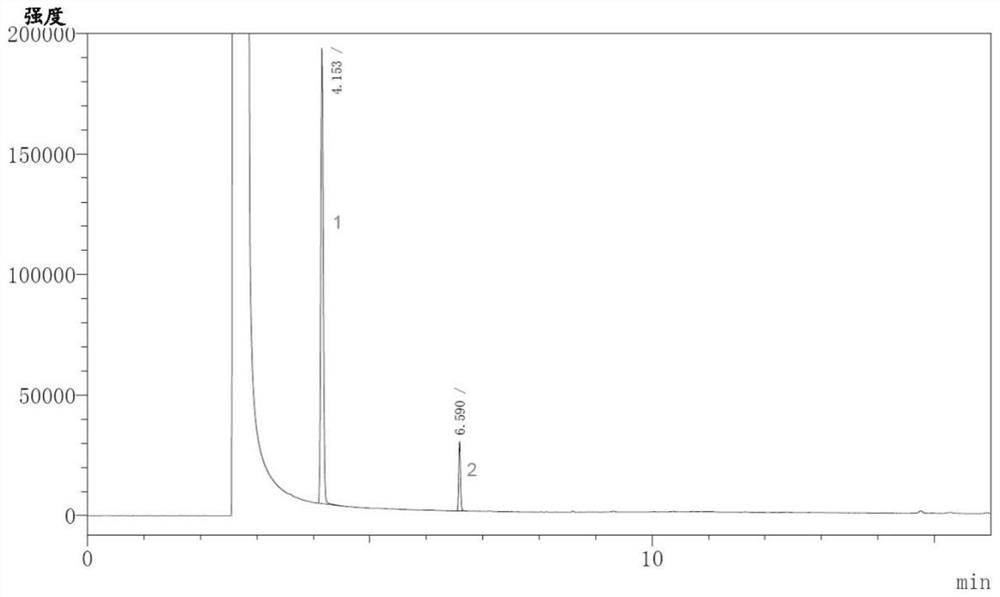

Embodiment 2

[0069] Polydioxanone sample: provided by Liaoning Yuanda Nuokang Biopharmaceutical Co., Ltd.

[0070] Instrument: Shimadzu gas chromatograph (GC-2010plus, workstation: GC Solution).

[0071] Chromatographic conditions: capillary column (30×0.25mm, 1.4μm) with 6% cyanopropylbenzene+94% methyl polysiloxane as stationary phase; the column temperature is programmed temperature: the initial column temperature is 40°C, and kept for 5min , the heating rate was 40°C / min, raised to 200°C, and held for 7min; the inlet temperature was 250°C; the hydrogen flame ionization detector was used, and the detector temperature was 260°C; the injection method was direct injection, and the split ratio was 20 : 1, injection volume: 1 μL; carrier gas is nitrogen, column flow: 1.45 mL / min.

[0072] (1) Preparation of the extraction solvent containing the internal standard: take n-hexane, accurately weigh it, dissolve it with propanol and dilute it into a solution containing 0.1 mg of n-hexane per 1 m...

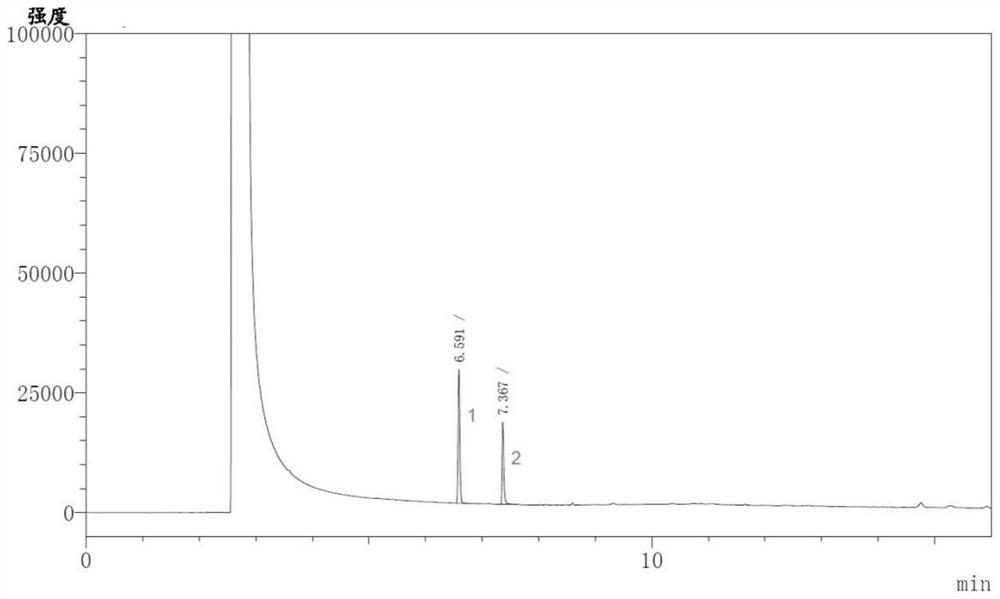

Embodiment 3

[0083] Polydioxanone sample: provided by Liaoning Yuanda Nuokang Biopharmaceutical Co., Ltd.

[0084] Instrument: Shimadzu gas chromatograph (GC-2010plus, workstation: GC Solution).

[0085] Chromatographic conditions: capillary column (30×0.25mm, 1.4μm) with 6% cyanopropylbenzene+94% methyl polysiloxane as stationary phase; the column temperature is programmed temperature: the initial column temperature is 40°C, and kept for 5min , the heating rate was 40°C / min, raised to 200°C, and held for 7min; the inlet temperature was 250°C; the hydrogen flame ionization detector was used, and the detector temperature was 260°C; the injection method was direct injection, and the split ratio was 20 : 1, injection volume: 1 μL; carrier gas is nitrogen, column flow: 1.45 mL / min.

[0086] (1) Preparation of extraction solvent containing internal standard: take n-hexane, accurately weigh, dissolve with ethanol / isopropanol (V / V=1 / 1) and dilute to a solution containing 0.1 mg of n-hexane per 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com