Oil-water well outside-pipe fluid channeling distributed optical fiber detection simulation device and use method thereof

A technology of distributed optical fiber and simulation device, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc. It can solve the problems of lack of test sample data, difficult detection, and poor technology maturity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

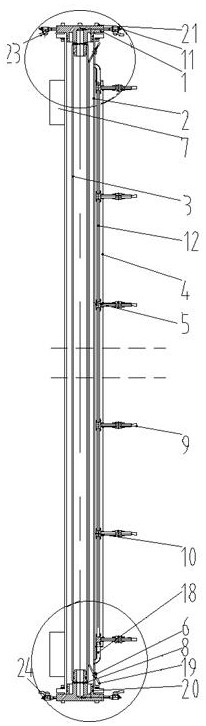

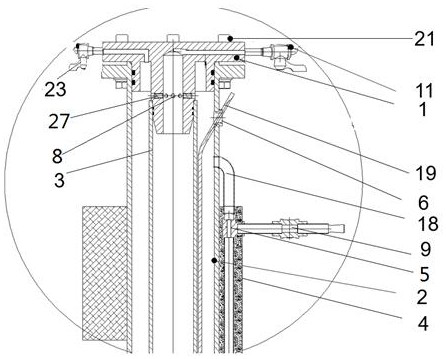

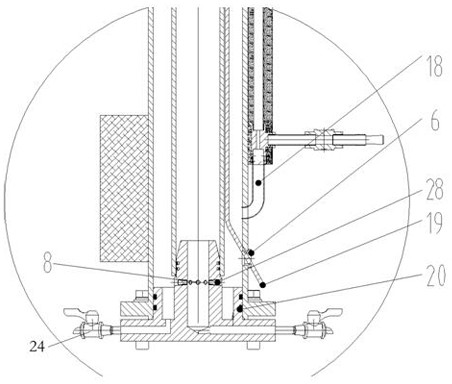

[0041] The wellbore simulator is provided with a simulated tubing 3, a simulated casing 2, a cement tank 4, a test fitting valve 9 and an elbow 18, and the two ends of the simulated tubing 3 and the simulated casing 2 are equipped with a flange 1 and a cement tank 4 Fixed on the outside of the simulation casing 2, the test pipe fitting valve 9 is installed on the cement tank 4 and communicated with the test pipeline 12 in the cement tank 4, the two ends of the cement tank 4 are equipped with elbows 18, and one end of the elbow 18 is connected to the simulation The oil casing annulus between the casing 2 and the simulated oil pipe 3 is connected, and the other end is connected with the test pipeline 12 in the cement tank 4. The flange 1 installed at both ends of the cement tank 4 is equipped with a flange capable of communicating with the simulated oil pipe 3. Oil pipe hydraulic control valve 11, oil jacket annulus inlet control valve 23 and oil jacket annulus outlet control val...

Embodiment 3

[0043] The test pipeline 12 installed in the cement tank 4 can be a metal straight pipe, bellows, high-pressure hose or variable diameter pipe; the distribution distance of the test pipe fitting valve 9 installed outside the cement tank 4 is equal to or greater than that of the optical fiber 19 in the cement tank 4. The length or detection accuracy of downhole sampling points. When on-site production adopts distributed acoustic wave sensing detection sensing technology, that is, DAS testing, the optical fiber 19 is lowered into the well with the oil pipe, and when the signal data detected by the optical fiber 19 in the lower well is consistent with the test sample data after the device test of the present invention , the actual channeling position and length in the well can be judged according to the actual penetration depth of the optical fiber 19.

Embodiment 4

[0045] The simulated casing 2 and the simulated oil pipe 3 can be 2m-3m casing nipples and tubing nipples, and the casing nipples and the tubing nipples are threadedly connected at both ends to the The casing nipple of the simulated casing 2 connected to the flange 1 is provided with an optical fiber through hole, and an optical fiber sealing head 6 is installed in the optical fiber through hole, and the optical fiber 19 is fixed on the outer wall of the simulated oil pipe 3 through an optical fiber clamp. The simulated casing 2 and the simulated oil pipe 3 are processed into casing nipples and tubing nipples to facilitate processing and transportation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com