An electric heating structure for the rotor of a pyrolysis equipment

A technology of electric heating and electric heating elements, applied in the direction of ohmic resistance heating parts, heating elements, etc., can solve the problems of wire rotation or shaking, wire influence heat dissipation, and large safety hazards, so as to reduce the possibility of cable damage and facilitate Removal and installation, reduce the effect of cable damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

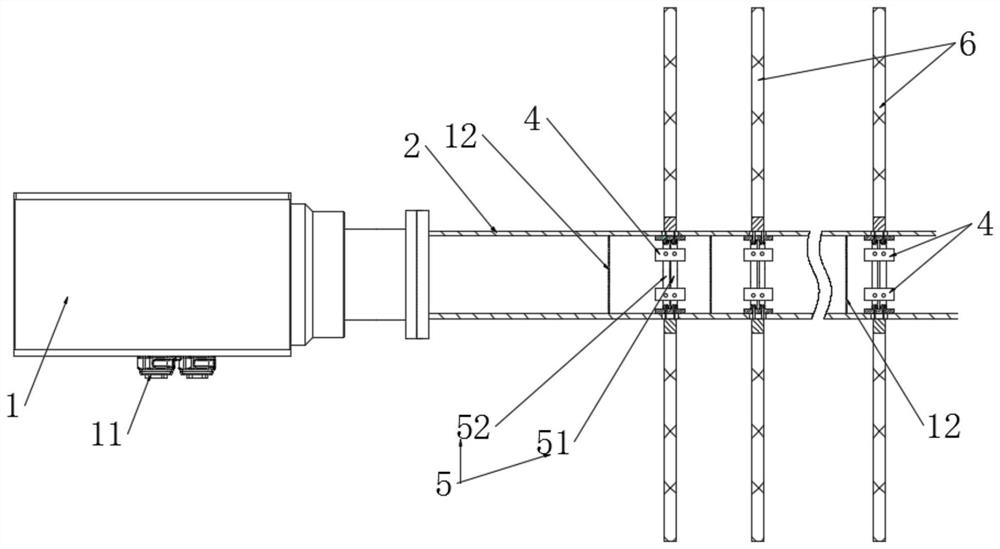

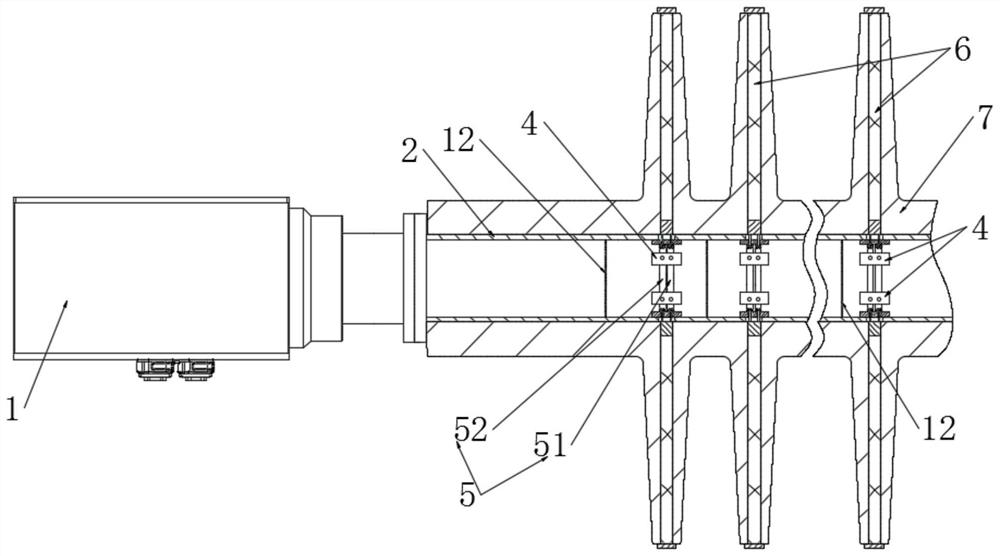

[0051] This embodiment provides an electric heating structure for the rotor of a pyrolysis equipment, see Figure 1-3 , including a rotor disc 7, the rotor disc 7 is distributed with several circles of electric heating zones in the axial direction, and a number of electric heating elements 6 are distributed in the circumferential direction of the electric heating zone, and one end of the electric heating element 6 is penetrated to the In the core hole of the rotor disc 7,

[0052] The electric heating structure further includes a hollow shaft 2, the hollow shaft 2 is arranged along the axial direction of the rotor disk 7, the outer wall of the hollow shaft 2 is adjacent to the inner wall of the core hole, and one end of the hollow shaft 2 is fixedly connected The rotating part of the slip ring box 1, the fixed part of the slip ring box 1 is connected to an external power supply, and a number of ring rows 5 are installed inside the hollow shaft 2 along its axial interval, and e...

Embodiment 2

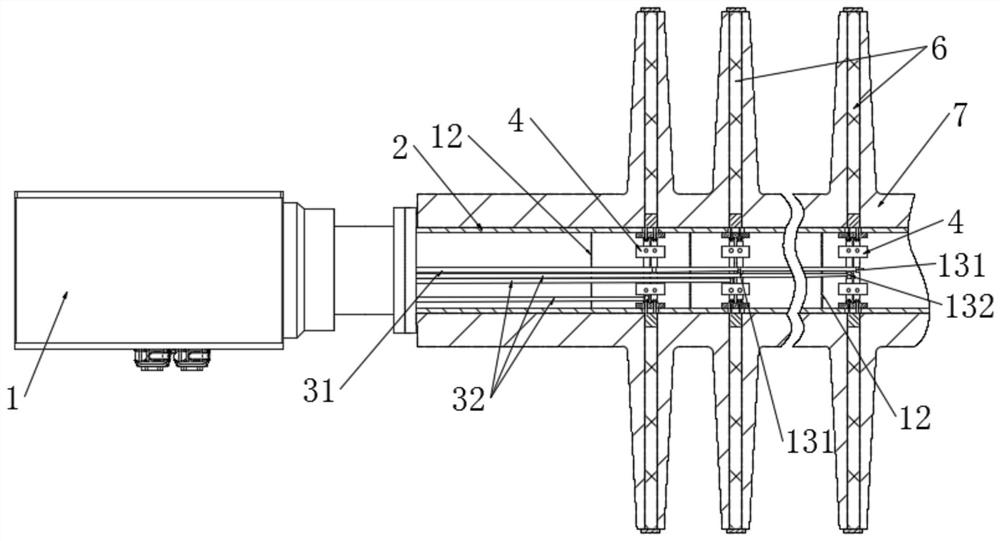

[0070] This embodiment provides an electric heating structure for the rotor of a pyrolysis equipment, which is different from Embodiment 1 in that, such as Figure 10 As shown, each of the neutral wire loops 51 is connected to the rotating part through a cable one 31 , and each live wire loop 52 is electrically connected to the rotating part through a cable two 32 .

[0071] In this solution, each ring row 5 needs to be connected with two cables, that is, the live wire ring 52 needs a cable 2 to 32 connection, and the neutral wire ring 51 needs a cable 1 to 31 connection. In this way, the communication of an external power source with the electric heating element 6 can also be achieved. By dislocating the cable one 31 connected to the neutral wire ring 51 and the cable two 32 connected to the live wire ring 52 in the hollow shaft 2, the installation space is provided, and the cable one 31 and the cable are lowered. Two 32 the possibility of mutual interference.

[0072] As a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com