Sludge discharge device for sewage treatment and use method

A sludge discharge device and sewage treatment technology, which is applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc., and can solve the problems of rust of equipment parts and large amount of sludge discharge. , to achieve the effect of prolonging service life, thorough sludge adsorption and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

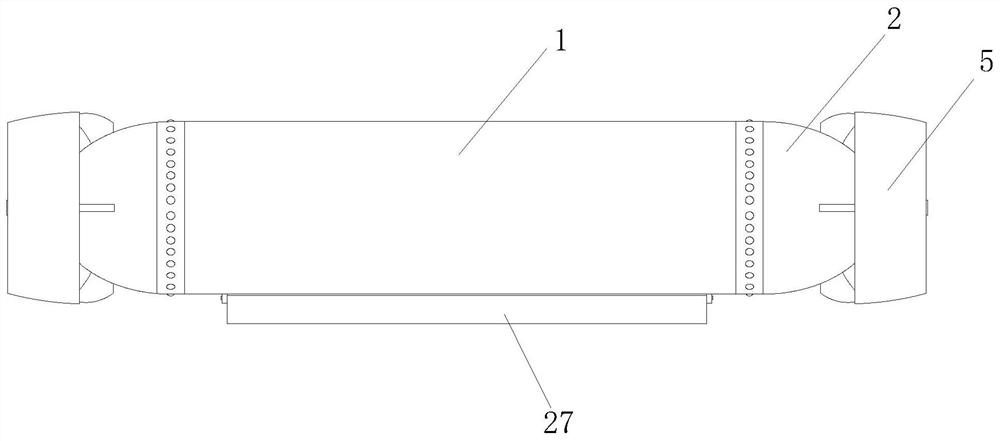

Embodiment 1

[0044] Embodiment one, according to Figure 1-Figure 6 , through the control of the control terminal 13, the water pump 15 is controlled to act, and at the same time, the first electric control valve 7, the second electric control valve 16 and the fourth electric control valve 20 are controlled to close, and the fifth electric control valve 31 and the third electric control valve 31 are opened. The valve 29 introduces the water above the sedimentation tank into the counterweight box 18 to make the tank 1 sink into the water. At the same time, the control terminal 13 starts the heating pipe 19 for heating. When the tank 1 is placed on the top of the sludge, the control terminal 13 controls to close The fifth electric control valve 31 and the third electric control valve 29 open the first electric control valve 7 and the fourth electric control valve 20, and start the sludge pump 6, and use the sludge pump 6 to pass the sludge at the bottom of the pool through the suction nozzle ...

Embodiment 2

[0045] Embodiment two, according to Figure 4 and Figure 7 , through the action of the output end of the electric cylinder 26, the baffle plate 27 is driven to swing, and through the swing of the baffle plate 27, the shifting block 28 is used to move, and the sludge is loosened with the relative movement of the shifting block 28, and then through the rotation of the paddle 4, water is realized. Downward stirring, through the strengthening of the stirring action and the swing of the toggle device 14, the sludge at the bottom is stirred to effectively deal with the stubborn contact between the sludge and the bottom of the tank, so that the sludge is more thoroughly adsorbed.

[0046] A method for using a sludge discharge device for sewage treatment, the steps of the method are as follows:

[0047] 1. Start the control terminal, put the tank in the water, control the water pump through the control terminal, close the first electric control valve 7, the second electric control v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com