Tool for precisely cutting bolted U-rib hand hole

A precision cutting, hand hole technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of cutting size and verticality out of tolerance, and achieve the effect of low tooling cost, guaranteeing stability, and guaranteeing use accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

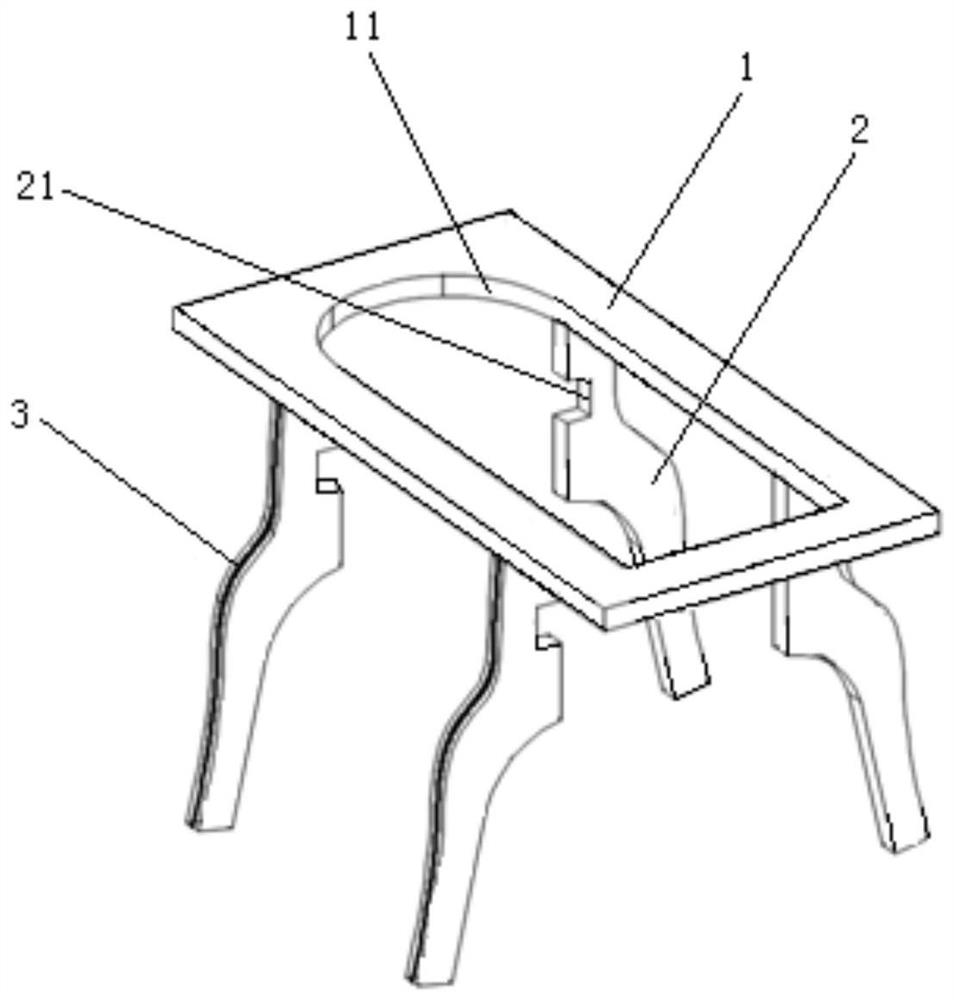

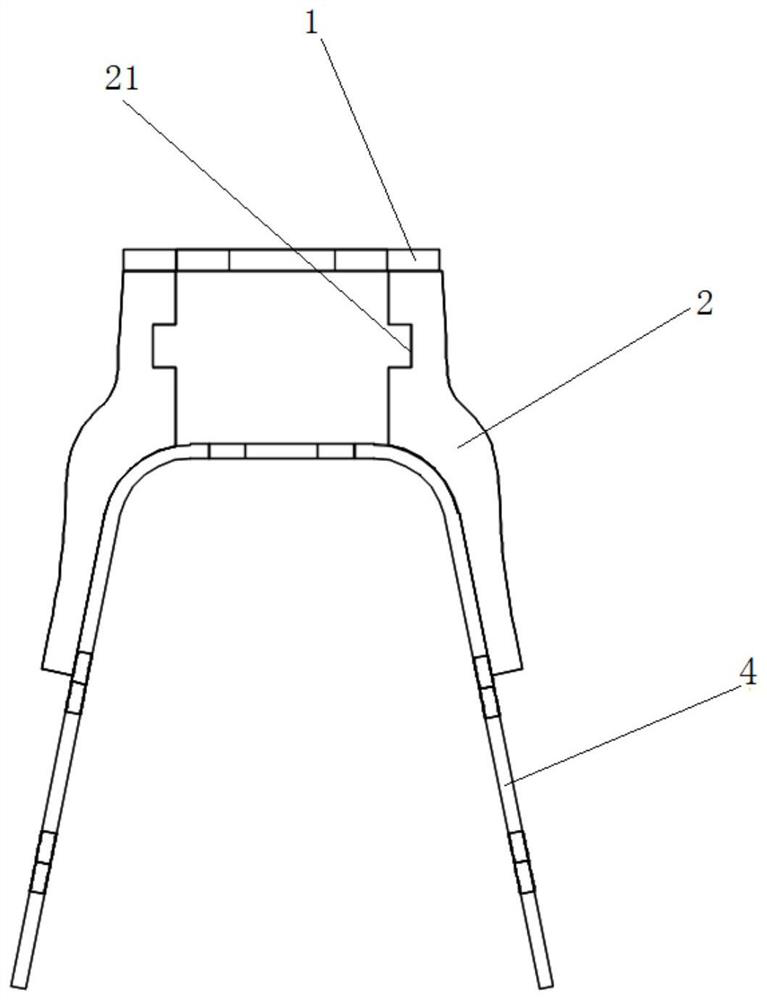

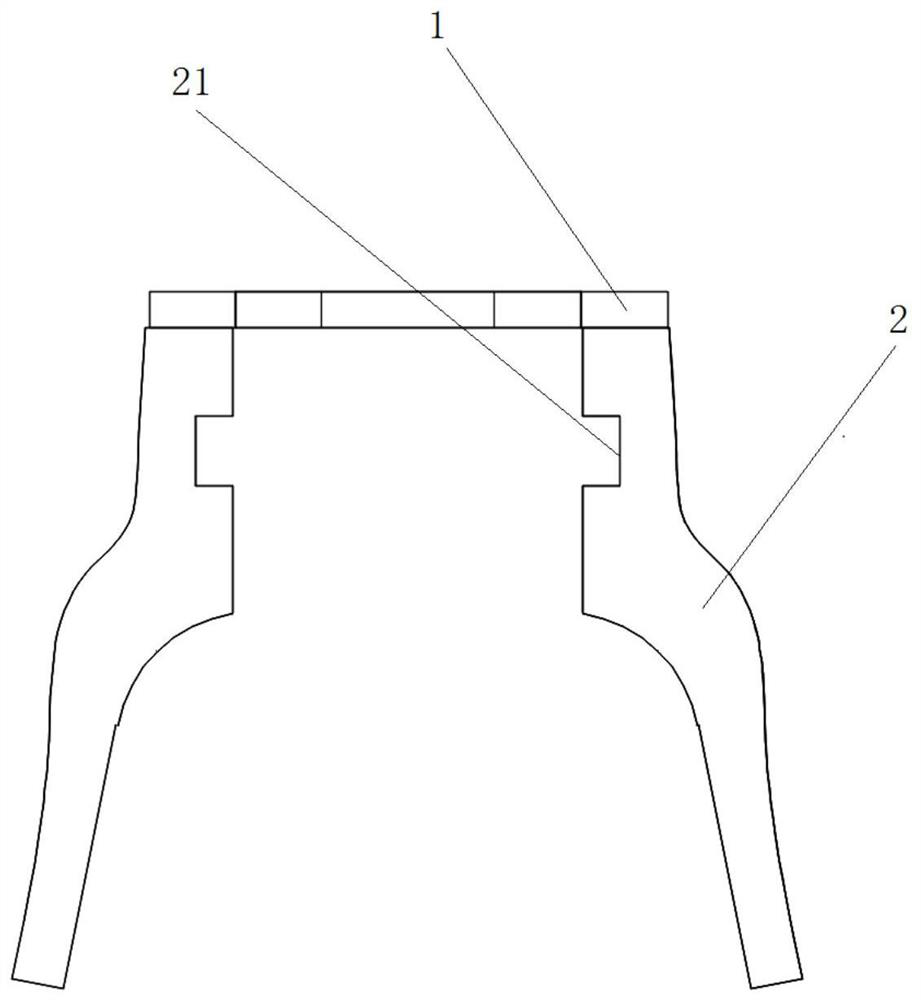

[0022] like Figures 1 to 6 As shown, the tooling of the present invention for bolting U-rib hand hole precision cutting includes a profiling model 1 and a support plate 2 .

[0023] The profiling sample 1 is a rectangular plate structure, which is arranged horizontally and kept parallel to the U rib 4 of the steel box girder plate unit; Through hole 11, and the inner hole wall at one end of the longitudinal direction of the profiling through hole 11 is a semicircle, and the inner contour of the profiling through hole 11 is on the same cutting plane as the U rib hand hole 41

[0024] There are four support plates 2, which are matched and symmetrically welded vertically on the left and right sides of the bottom of the profiling template 1 in groups of two. The side of each support plate 2 facing the U rib 4 of the steel box girder plate unit is an inner section, and each The side of the four supporting plates 2 facing away from the U rib 4 of the steel box girder plate unit is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com