Steel profile laser derusting and spraying integrated device with stepless speed control function

A technology of laser rust removal and steel profile, applied in the direction of spray device, auxiliary device, laser welding equipment, etc., can solve the problems of reducing the quality and efficiency of rust removal and spraying, difficulty in determining the movement speed, uneven rust removal, etc. The effect of comprehensive rust removal and spraying, improving quality and efficiency, and increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

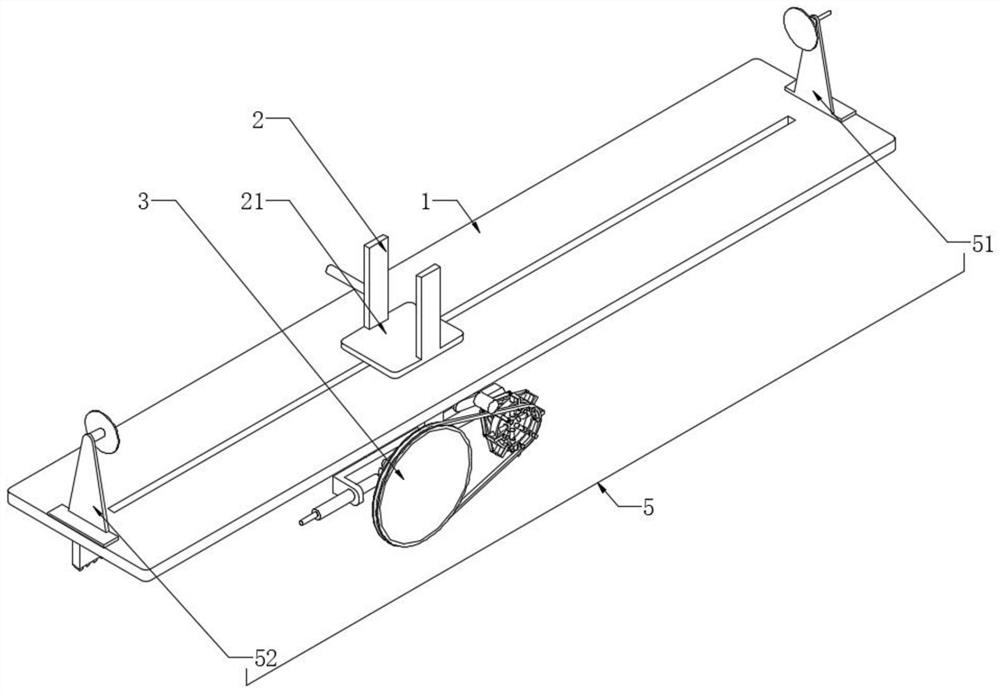

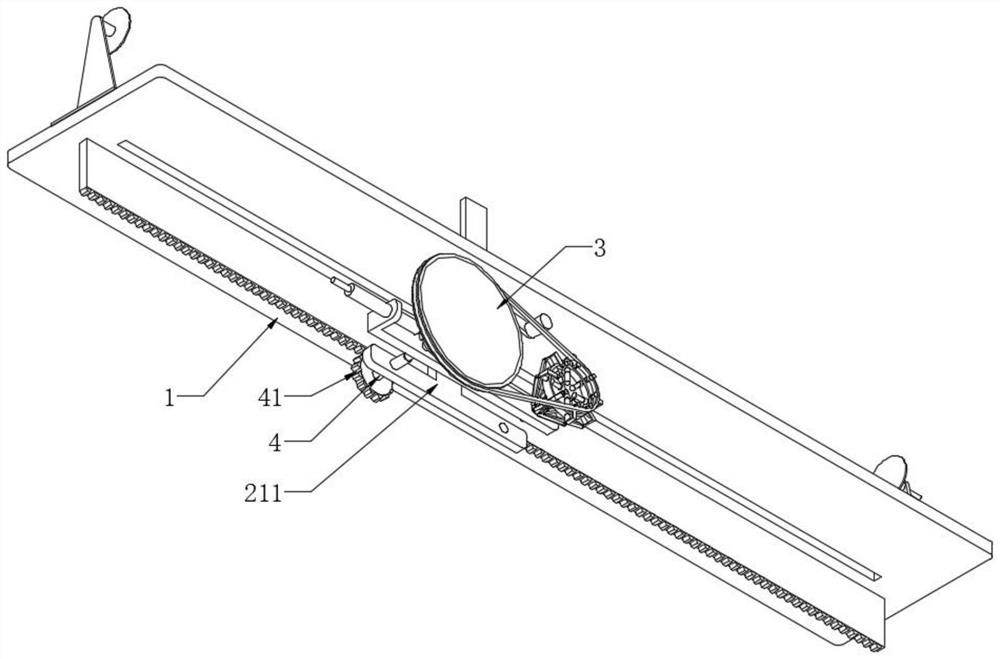

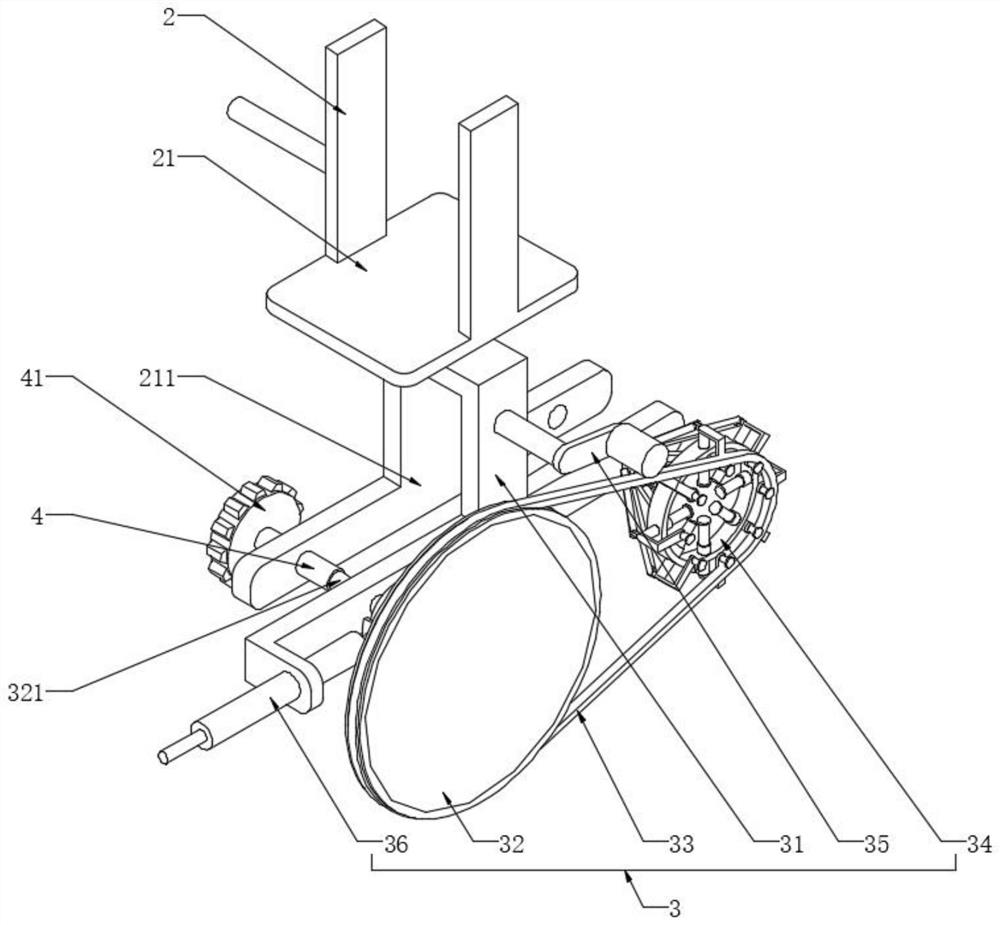

[0028] see Figure 1-4 , an integrated device for laser rust removal and spraying of steel profiles with stepless speed control, including a bearing positioning plate 1, a profile rust removal and spraying frame 2 and a centrifugal stepless speed controller 3, the bearing positioning plate 1 is used to support the profile The derusting spray frame 2 and the centrifugal stepless speed controller 3, the profile derusting spray frame 2 can be provided with the mounting plate of the laser derusting equipment and the spraying equipment, and the profile derusting spray frame 2 is provided with and bearing positioning plate 1. One side of the guide plate 21 that slides and fits, one side of the guide plate 21 is fixedly provided with a drive plate 211, the drive plate 211 is rotatably connected with a drive shaft 4, and one end of the drive shaft 4 is fixedly connected with the other end of the bearing positioning plate 1. The side meshing transmission gear 41 can install a rack mesh...

Embodiment 2

[0030] see image 3 and 5, and the difference from Embodiment 1 is that the centrifugal stepless speed controller 3 also includes a damping adjustment mechanism 36, and the fixed sleeve on the wheel shaft 321 is provided with a wear-resistant wheel 3211, and the damping adjustment mechanism 36 is arranged on the connecting frame 31 and is connected with the wear-resistant wheel 3211, wherein the damping adjustment mechanism 36 includes a fixed guide sleeve 361, a guide rod 362, a damping plate 363, an extrusion spring 364 and a screw rod 365, and one end of the guide rod 362 is sleeved in the fixed guide sleeve 361 and is a sliding fit. The other end of the guide rod 362 is fixedly connected to one side of the damping plate 363, the other side of the damping plate 363 is opposite to the outer peripheral wall of the wear wheel 3211, and one end of the screw rod 365 is screwed to the other end of the fixed guide sleeve 361. , the extrusion spring 364 is sleeved in the fixed gui...

Embodiment 3

[0032] see figure 1 , and the difference from Embodiment 1 is that the bearing positioning plate 1 is provided with a clamping turntable assembly 5, the clamping turntable assembly 5 includes a rotating baffle 51 and a clamping disk 52, and the clamping turntable assembly 5 is used to process the steel profile Clamping and positioning, and at the same time, it can be turned over to realize comprehensive derusting and spraying of steel profiles. The clamping action of the clamping disc 52 adopts a common screw rotation control clamping structure. At one end of the plate 1 , the clamping disc 52 is arranged at the other end of the bearing positioning plate 1 and is opposite to the rotating stopper 51 .

[0033] Working principle: when in use, place the load-bearing positioning plate 1 horizontally, then place the steel profile to be treated between the rotating baffle plate 51 and the clamping plate 52, and install laser derusting equipment and spraying equipment on the profile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com