Laser welding production process for baking plate

A laser welding and production process technology, applied in the field of baking plates, can solve the problems affecting the integrity and aesthetics of the baking plate, irregular welding bead, easy to produce breakpoints, etc., to achieve beautiful appearance, neat and smooth welding bead, and increased precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with specific examples.

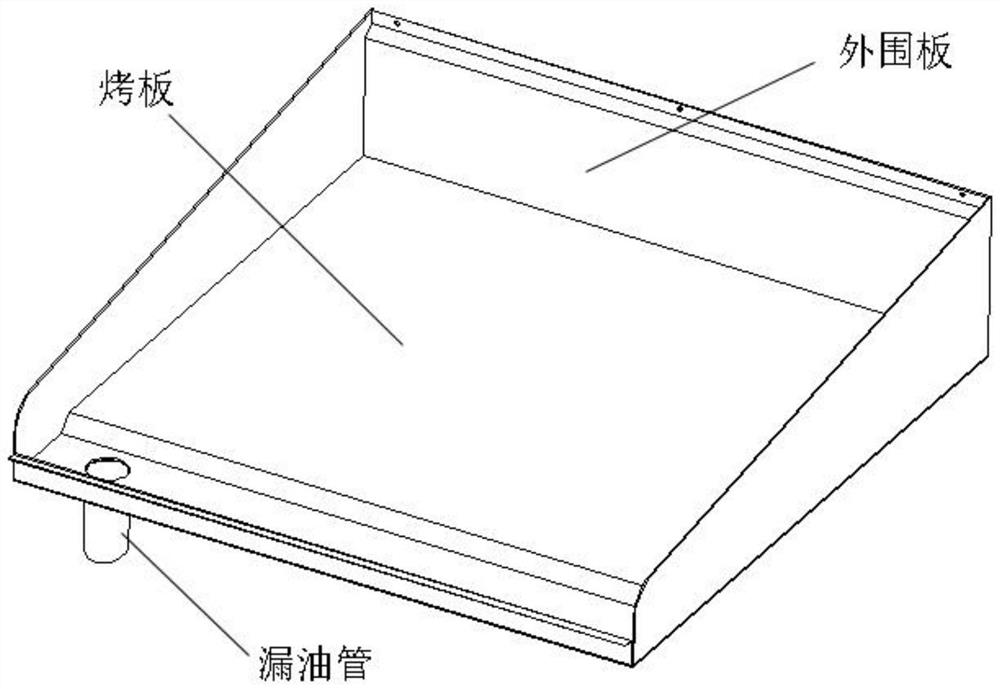

[0020] Such as figure 1 Shown, a kind of laser welding production technology of baked plate comprises the following steps:

[0021] Step 1: Plate selection. The baking plate is made of national standard 45# material with a thickness of 10-30MM. The peripheral plate is made of metal material with a thickness of 1-3mm. The material size is plus or minus 0.1mm. The oil leakage pipe is made of metal pipe.

[0022] Step 2: Cutting process, the baking sheet in step 1 is cut to the required size by gas cutting, then the surface is roughly ground by a grinder, the four sides are processed by a CNC flashing machine, and the back is chamfered by a chamfering machine deal with.

[0023] Step 3: Fine carving processing, put the baking plate in the flat state that has undergone rough grinding treatment in step 2 into the fine carving machine for plane slot milling, slope milling and oil leak hole milli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com